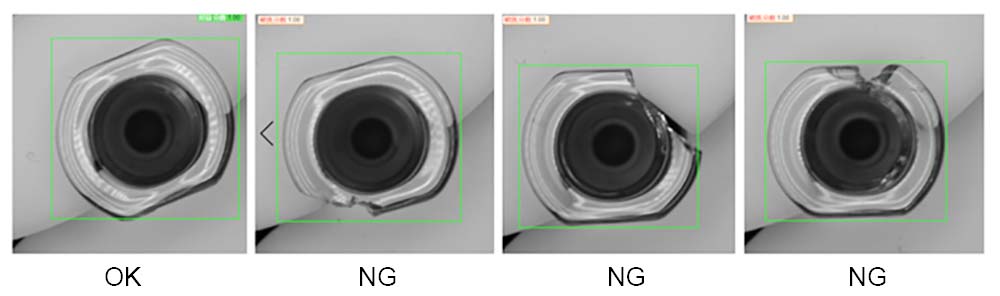

The computer determines whether the liquid contains foreign matter, whether the bottle has appearance defects and other defects according to the software algorithm. If foreign matter or defects are identified, the software will send instructions to sort defective products out of the conveyor belt through PLC control, and if they are qualified products, they will enter the next stage of the process.

Detailed inspection requirements:

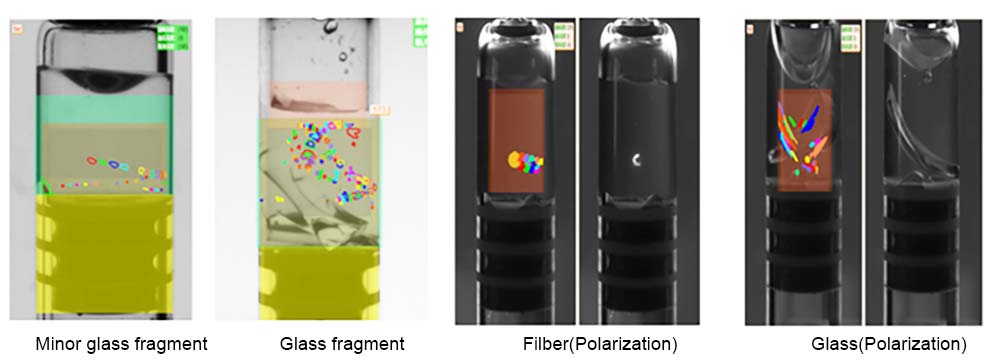

Inspect foreign matter in liquid medicine to determine whether there is foreign matter such as glass and cilia;

Inspect the surface of the container for foreign matter to determine whether there is foreign matter on the flange, rubber plug, needle cover, outer surface of the bottle body, and side of the rubber plug.

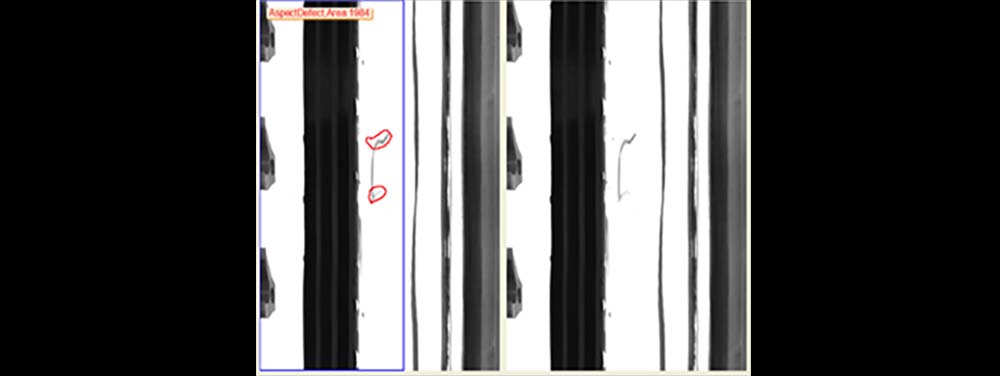

Inspect the glass container surface for defects in the outer surface of the glass container and the outer surface of the rubber plug.

Inspection difficulties:

1. There are many parts to be inspected,including needle cap, rubber stopper, upper part of bottle, lower part of bottle, liquid and other part

2. The layout of the inspection station is compact, and the inspection needs to be completed in a compact space.

3. High requirements for inspection accuracy and stability, and strict requirements for the fault tolerance of drug testing.

4. Both the bottle body and the rubber stopper are arc-shaped, and it is difficult to take pictures of defects.

5. There is a lot of interference in foreign materrecognition, and there are many environmental interferences, such as bubbles, reflection of light.

6. High requirements for inspection speed and efficiency directly affect production capacity.

Solution

1. Specific configuration: acA1300-200um*16-20pcs. Use 16-20 cameras to take pictures and analyze images of different parts.

2. Multi-station photography and multi-image analysis ensure complete visual analysis of objects.

3. Use multiple cameras to extract images of surface cracks, rubber plug appearance, etc. Based on advanced visual algorithms and deep learning algorithms, analyze and identify whether it is damaged or dirty.

4. High-speed continuous multi-shot, using multi-image comparison to identify foreign matters. Use AI algorithms to learn bubble movement trajectory, use shapes to distinguish bubbles and tiny glass fragments, and detect the amount of medicinal liquid and foreign matter (such as glass, metal objects, white spots, black blocks, color blocks, cilia, hair and other foreign objects).

Configuration features:

Multiple camera systems can take photos in a comprehensive and multi-station manner, which is more accurate, comprehensive and efficient than taking photos with a single camera. At the same time, this solution solves the difficulty of stable coordinated transmission of multiple cameras on the USB 3.0 interface.

Solution Advantages

1. The stable combination of Basler multiple cameras can fully meet the customer’s multi-part inspection needs and continuously and effectively output high-quality images. At the same time, the compact Basler camera structure can adapt well to narrow installation spaces.

2. Basler line scan cameras can more fully display arc surface defects and solve the problem of photographing defects on the outer surface of the arc.

3. With TRUKING’s mature visual algorithm and advanced AI algorithm, the light inspection machine can fully cope with different inspection contents, eliminate external interference, and improve inspection accuracy.

4. The automatic light inspection machine replaces the traditional manual visual inspection, which greatly plays the advantages of inspection efficiency and accuracy.