Email:

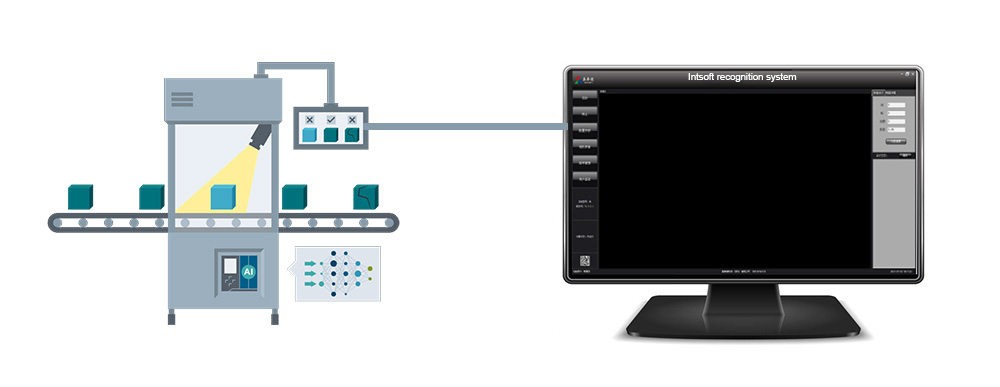

Machine vision inspection is a very wide range of applications. It can be introduced to a variety of production operations in the production line to reduce production costs and improve product quality, so that your products or other operations achieve a pass rate of 99.9%. As a software system for machine vision inspection, Visual Inspection System provides a series of core functions such as algorithms, programs, etc. for machine vision inspection.

No matter what industry you are in, if there are repetitive steps in the production process, we can integrate our technology into your production operations to make it more automated and intelligent. Let the machine plus eyes and brain, freeing up manpower, let the machine do this heavy and repetitive work.

Since the establishment of 2017, we have focused on developing intelligent manufacturing equipment for the production of enterprises, including software systems for detection, statistics, sorting, monitoring, etc. that need to be implemented in production, and hardware such as whole production lines or special customized functions such as inspection machines. In short, we have powerful technology that can make your production work smarter.

If you are already familiar with machine vision inspection, you can learn about

1. Correct defect categorization

Intsoft-AI vision inspection system series, using artificial intelligence technology, self-learns for user-defined defect categories, accurately classifies defects according to the more subtle differences in defect categories, and achieves reliable classification of different defects detected.Intsoft-AI’s defect classification function greatly enhances the whole process of quality monitoring, product grading, and process improvement.

2. Machine vision intelligent defect database

We can establish a defect database, and contain defect images and defect location and all defect characteristics of a comprehensive defect database, in addition to improving defect detection and classification.

3. Intelligent output in detection results

We can be prompted by external alarm lights or other external alarm devices, and users can view them through tables, graphs and other ways. Machine intelligence software can automatically analyze this part of the data for statistics, and generate the relevant trend curve and chart.

4. Easy to use interface

System Main Interface

Model Management System Interface

Equipment Failure Alarm System Interface

Parameter Setting System Interface

Intsoft Technology developed a series of smart inspection systems, include tablet visual inspection system for pharmaceutical industry, fruit sorting system for agriculture, shoes and 3C electronic components inspection system for manufacturing, etc.