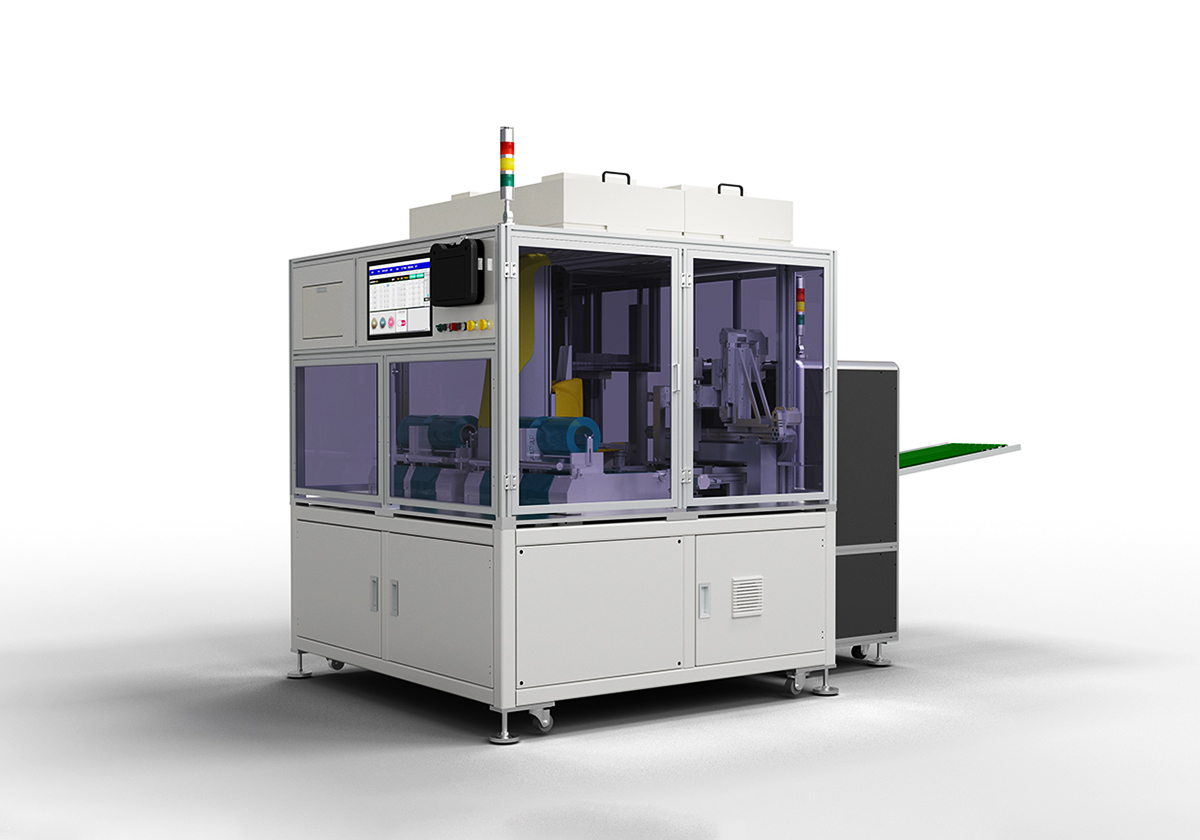

This light guide plate (LGP) defect detection equipment integrates a horizontal four-joint robot, automatic cleaning machine, laminating device and advanced CCD AI software. It can scan the LGP surface comprehensively and accurately locate various defects including white spots, scratches and stains. The horizontal four-joint robot has flexible movement and precise positioning, and cooperates with the intelligent analysis of CCD detection software to greatly improve detection efficiency and provide manufacturers with reliable quality assurance.

Unveiling the Importance of LGP Quality

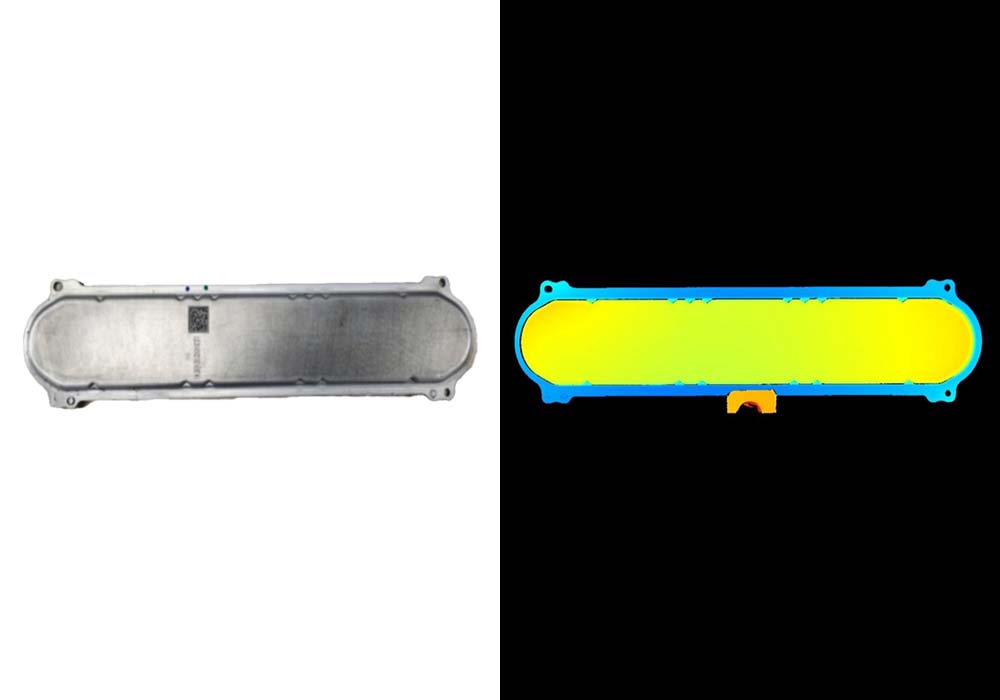

The light guide plate is responsible for distributing the light emitted by the backlight evenly across the display panel. Any imperfections or defects in the LGP can lead to uneven brightness, color inconsistencies, and other visual artifacts that severely compromise the overall image quality. Therefore, comprehensive inspection and testing of LGPs has become a crucial step in the manufacturing process.

Introducing LGP detection equipment

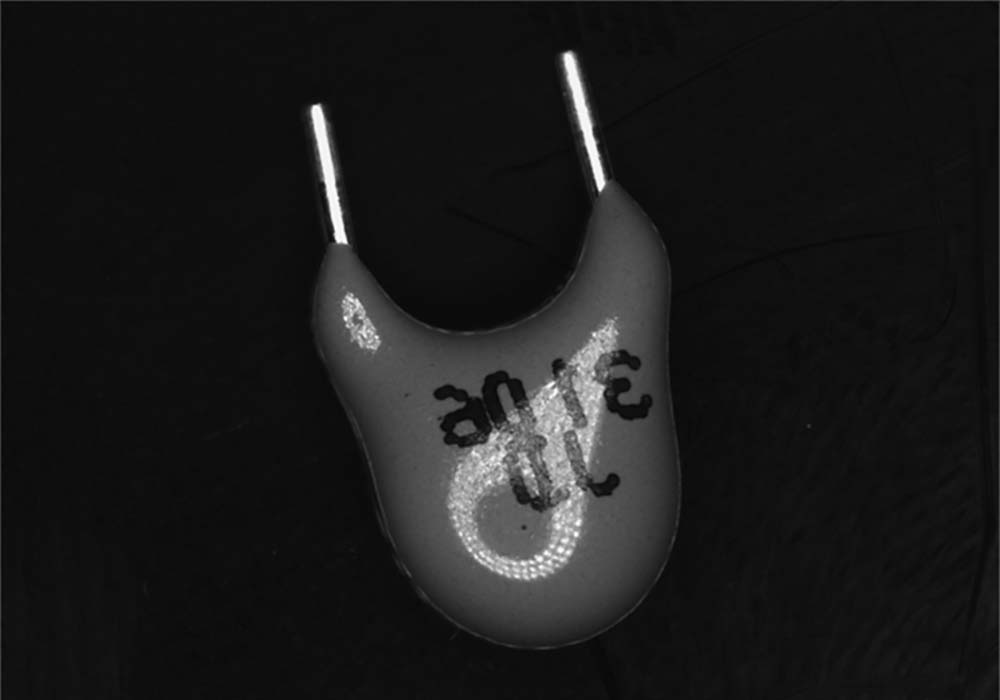

Our state-of-the-art LGP detection equipment is designed to thoroughly analyze and evaluate the quality of light guide plates with unparalleled precision. These advanced systems leverage a combination of cutting-edge technologies, including high-resolution cameras, advanced optical sensors, and sophisticated image processing algorithms to detect even the most subtle defects.

Comprehensive Inspection Capabilities

LGP detection equipment is capable of performing a wide range of inspections, including surface irregularities, thickness variations, optical transmittance, and luminance uniformity. By accurately measuring these critical parameters, our solutions enable manufacturers to ensure consistent quality and performance of their light guide plates, ultimately enhancing the visual experience for end users.

Parameter

| Items | Parameter |

| Dimension | 1720*1500*2100(L*W*H) |

| Weight | 800KG |

| Working condition | Voltage 220v/ Power 3KW/Temperature under 50℃ |

| Working environment | Dust-free, humidit 20%-80% |

| Inspectable size of product | Max 203mm |

| Inspect speed | Based on specific parameters of the product |

Streamlined workflow and efficiency

Designed with efficiency in mind, LGP detection equipment seamlessly integrates into production lines, enabling real-time monitoring and automated defect detection. This not only streamlines the quality control process, but also minimizes production downtime and enhances overall manufacturing productivity.

Driving Innovation in Display Technology

As the display industry continues to push the boundaries of innovation, the role of LGP detection equipment becomes increasingly vital. By empowering manufacturers to maintain the highest standards of quality, our solutions contribute to the development of next-generation display technologies that captivate and engage audiences around the world.

Experience the difference our LGP detection equipment can make. Elevate your display production to new heights and deliver unparalleled visual experiences with our cutting-edge solutions.