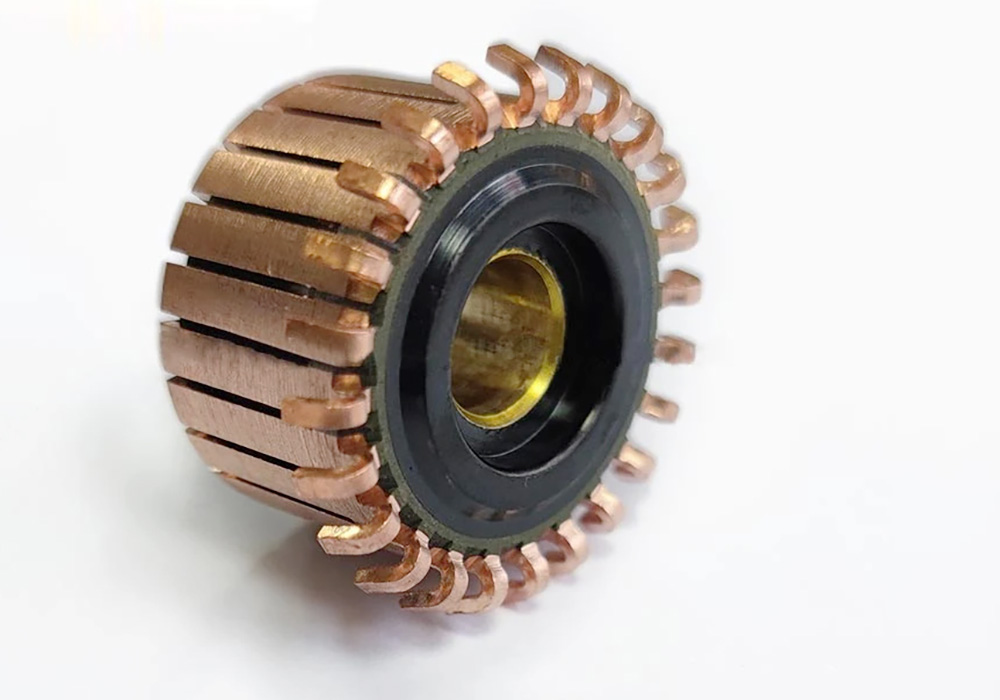

The motor commutator can realize the bi-directional rotation of the motor, which is suitable for occasions that need to change the steering of the motor frequently. At the same time, the commutator can also control the motor speed, making the motor run more smoothly. The disadvantage is that the commutator’s life is relatively short and needs to be replaced frequently. Commutators are widely used in a variety of DC motors, including household appliances, industrial production equipment, automotive motors and so on.

The quality of this fragile part, which is at the heart of the machine – the “motor” – must be strictly checked to ensure that the already fragile characteristics are not subject to additional defects!

Our inspection solution

After our experimental comparison, we found that in the visual inspection scheme, the use of dual telecentric lenses with backlight or parallel light projection techniques, while using the detection of circumferential dimensions, can be very good to achieve the bad judgment of the shape contour.

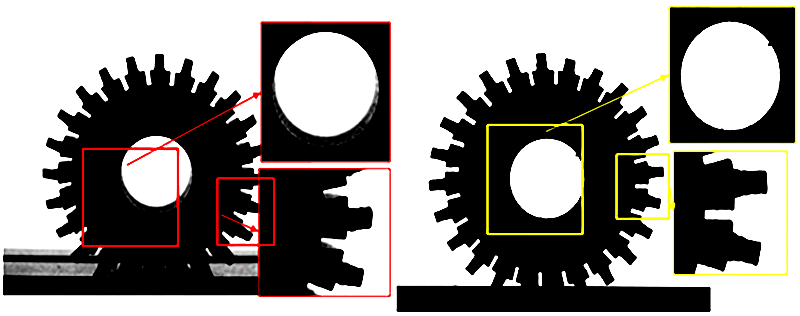

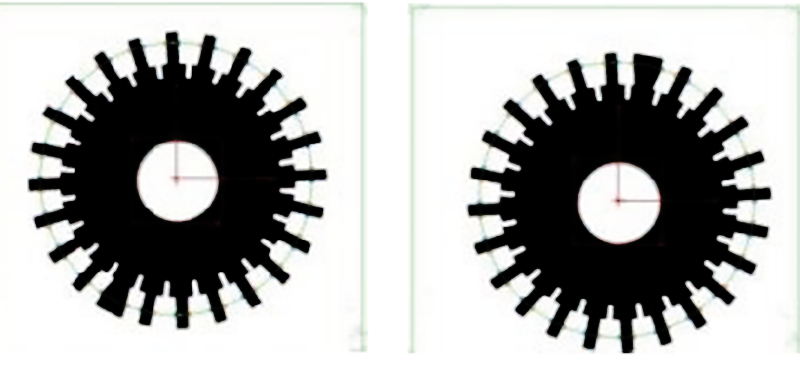

The following images show the actual results taken with the optical system consisting of a normal lens and a dual telecentric lens, respectively:

This program we use a set of BTOS double telecentric system, from the figure we can see, double telecentric optical system of the full projection shooting effect, no vertical and horizontal parallax, completely solved the parallax problem due to the thickness of the sample. At the same time, it can also effectively avoid the effect of various miscellaneous reflections, greatly improve the sharpness of the edge of the picture, and completely solve the problem of metal edge reflections.

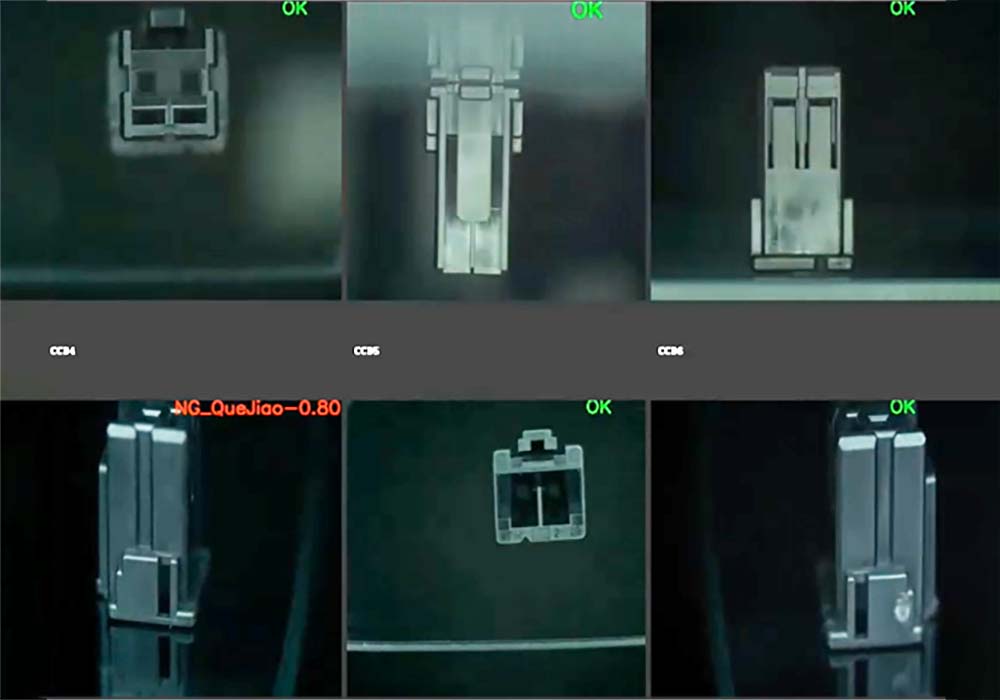

In the inspection, we use Intsoft Technology’s intelligent vision measurement software, which can provide a variety of positioning functions, to realize that the workpiece can be placed at random and can accurately detect its size. With the dual telecentric system “zero distortion” of the excellent characteristics of the system, it can greatly reduce distortion to bring the impact of measurement accuracy.

Intsoft Technology has been engaged in the machine vision industry for many years, and its products cover a wide range of fields such as image acquisition equipment, dual telecentric product equipment, intelligent vision inspection system equipment and school education equipment, which are highly recognized by customers in the industry. If your production line needs vision inspection technology, do not hesitate to contact us. We will give you professional advice, so that you can realize automated production.