The Y-shaped 3-way splitter for air conditioners is used to redistribute airflow, dividing the airflow of the air conditioner into two equal paths to supply different spaces. A qualified splitter should have smooth, rounded bends to reduce friction and turbulence, minimize wind resistance, and make airflow flow smoother.

Factory detection of these key components is also taken very seriously by air conditioner manufacturers. The following is the specific procedure for detecting these 3-way splitter with our equipment.

Inspection requirements:

Appearance inspection of products with maximum dimensions of 20mm length 20mm width, 5mm thick.

| No. | Position | Method | Detectability |

| 1 | Surface defect | Positive light detected | Yes |

| 2 | Bottom defect | Positive light detected | Yes |

Note: Precision hardware fittings detecting equipment automatically detect items, all need to be clearly visible under the image to be detected.

Detection efficiency: the number of detections per minute is not less than 120 pieces (depending on the product feeding speed).

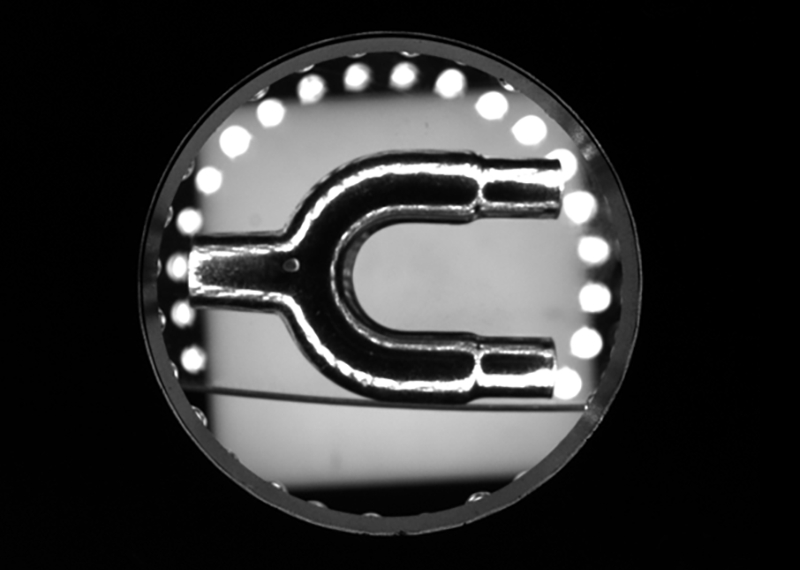

Sample image:

Machine structure

Precision hardware fittings detecting equipment composition and main institutions Equipment Model: YTD-T300 Non-standard custom machine, Overall dimensions: 900*800*1850mm, partial parts list as follows:

| No. | Name | Model | Quantity | Remark | |

| 1 | Visual inspection software | Intsoft customized | 1 set | Data can be upload | |

| 2 | Industrial computer | Intsoft customized | 1 set | ||

| 3 | Monitor | PHILIPS 19 “LCD monitor | 1 set | ||

| 4 | Industrial camera | Barsler industrial camera | 2 sets | ||

| 5 | Servo Module for Camera Adjustment | Intsoft customized | 2 sets | ||

| 6 | Industrial lens | FA High Definition Optical Industrial Lens | 2 sets | ||

| 7 | Light source | Customized optical adaptive light source | 2 sets | ||

| 8 | Inspection Platform | Professional Optical Glass Carrier | 1 set | ||

| 9 | Servo Motor | Panasonic | 1 set | ||

| 10 | Control System | Intsoft customized | 1 set | ||

| 11 | PLC motion collaboration | Panasonic | 1 set | ||

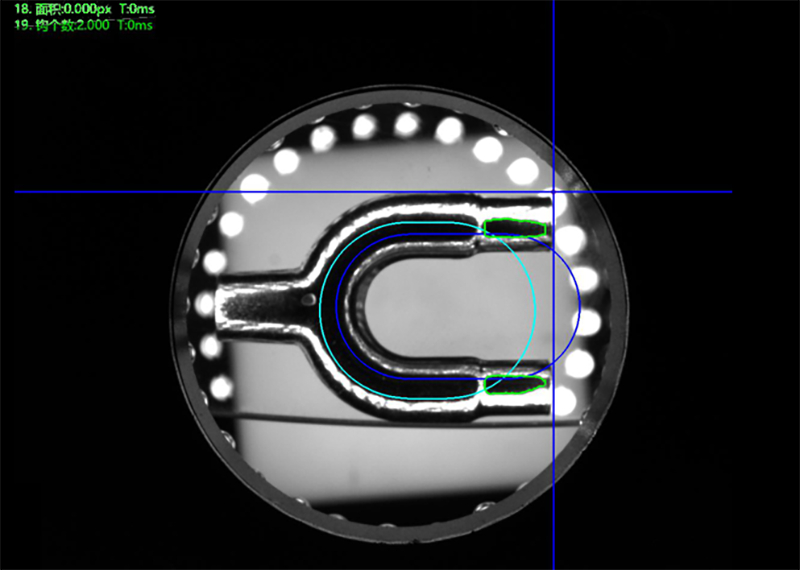

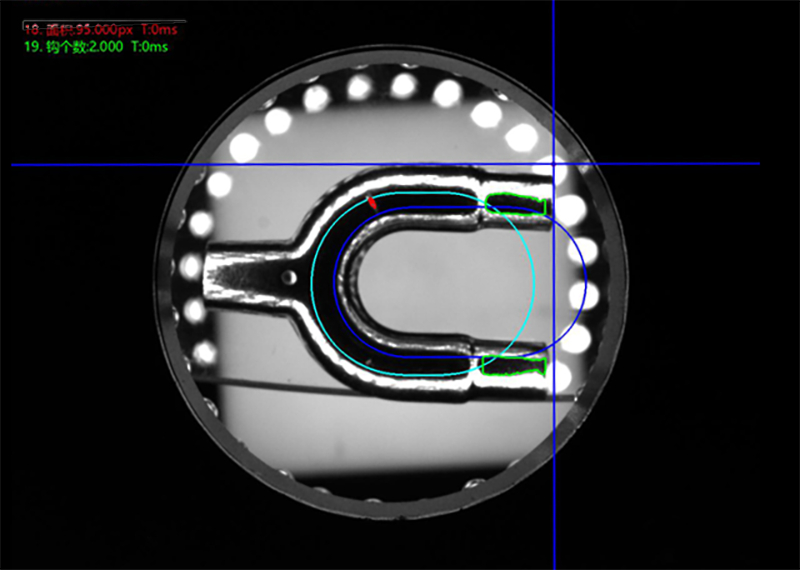

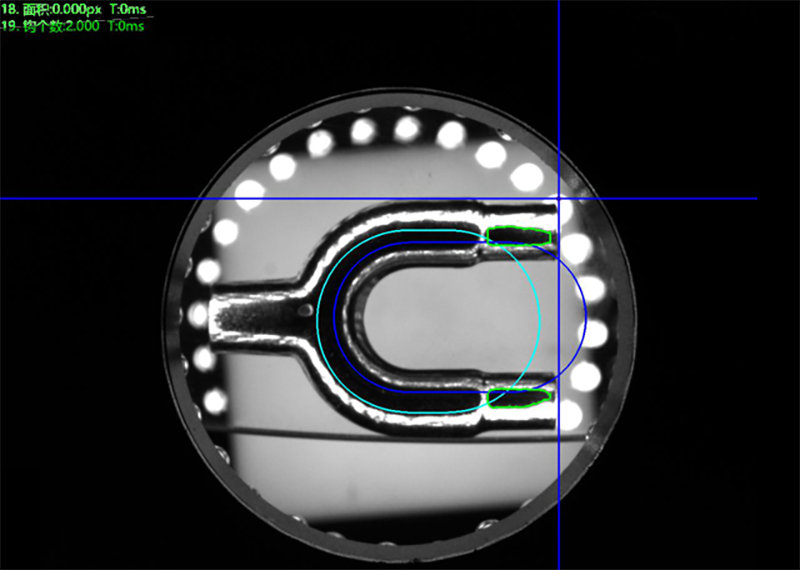

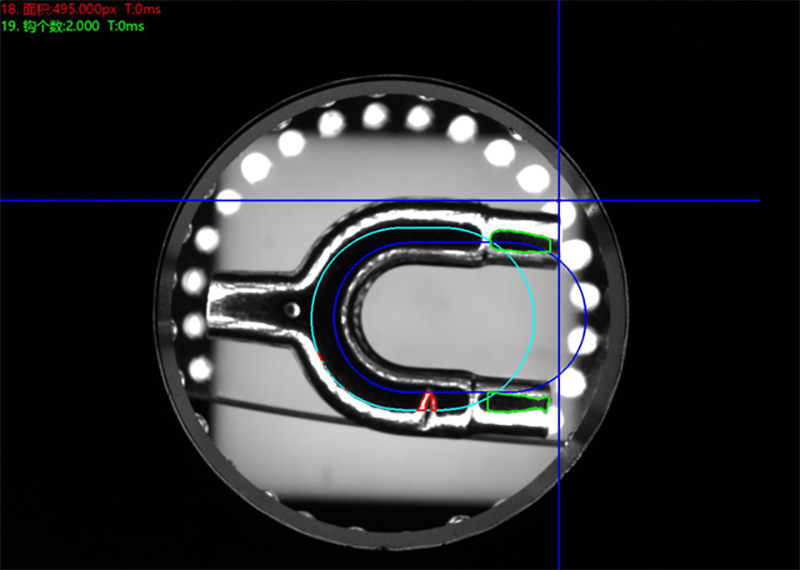

Detected splitter Image

Bottom inspection

Bottom positive light original image

Bottom positive light good product analysis image

Bottom positive light defective product analysis image, Cause of defective: Scratch

Top inspection

Top positive light good product analysis image

Top positive light defective product analysis image, Cause of defective: Scratch

Machine vision inspection equipment installation requirements

Equipment placed in the inspection area: the installation of Intsoft Technology vision inspection system of the overall inspection equipment, needs to ensure that there is enough space to install the equipment.

Ambient temperature: 0-50 degrees Celsius

Air humidity: 90% RH or less;

Electronic interference: Provide a place with less electronic interference for the equipment.

Power supply: AC 220V, 50Hz, power consumption <1KVA.