The importance of bearing hardware in various applications is significant. Bearings are essential components for the smooth and efficient operation of machinery, equipment and devices.

The following is a detailed record of the bearing accessories machine vision inspection.

Inspection content and requirements

| No. | Position | Method | Detectibility | Remark |

| 1 | Plating fouling | 360° detection | YES | 360° lens only sees features > 5cm², no color differences detected. |

| 2 | Plating slag | 360° detection | YES | |

| 3 | Corrosion | NO | ||

| 4 | Burr | Top backlight detection | YES | Slot burr undetectable |

| 5 | Foreign matter | Top backlight detection | YES | |

| 6 | Color changing | NO |

Note: Precision hardware fittings detecting equipment automatically detect items, all need to be clearly visible under the image to be detected.

Detection efficiency: the number of detection per minute is not less than 200 pieces (depending on the product feeding speed).

Sample image:

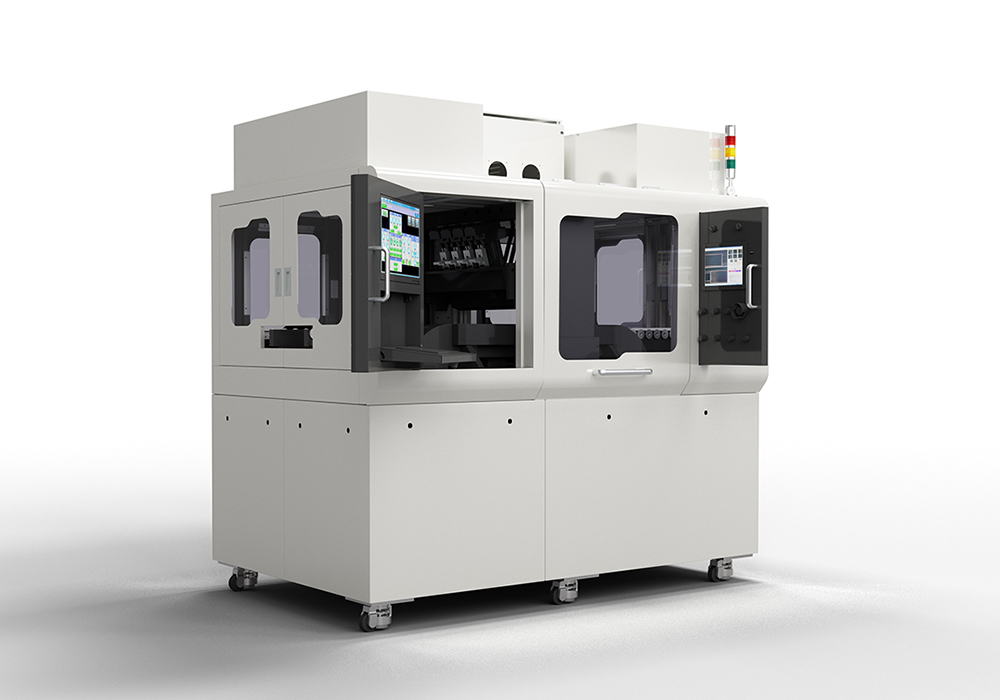

Machine structure

Precision hardware fittings detecting equipment composition and main institutions Equipment Model: YTD-T300 Non-standard custom machine, Overall dimensions: 900*800*1850mm, partial parts list as follows:

| No. | Name | Model | Quantity | Remark | |

| 1 | Visual inspection software | Intsoft customized | 1 set | Data can be upload | |

| 2 | Industrial computer | Intsoft customized | 1 set | ||

| 3 | Monitor | PHILIPS 19 “LCD monitor | 1 set | ||

| 4 | Industrial camera | Barsler industrial camera | 3 sets | ||

| 5 | Servo Module for Camera Adjustment | Intsoft customized | 3 sets | ||

| 6 | Industrial lens | FA High Definition Optical Industrial Lens | 1 sets | ||

| 7 | Industrial lens | 360° detectable industrial camera | 2 sets | ||

| 8 | Light source | Customized optical adaptive light source | 1 sets | ||

| 9 | Inspection Platform | Professional Optical Glass Carrier | 1 set | ||

| 10 | Servo Motor | Panasonic | 1 set | ||

| 11 | Control System | Intsoft customized | 1 set | ||

| 12 | PLC motion collaboration | Panasonic | 1 set | ||

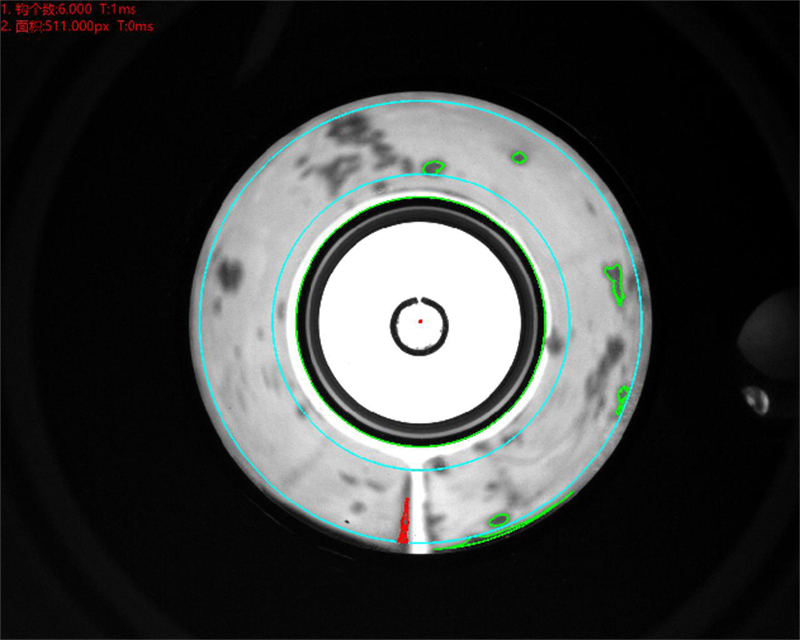

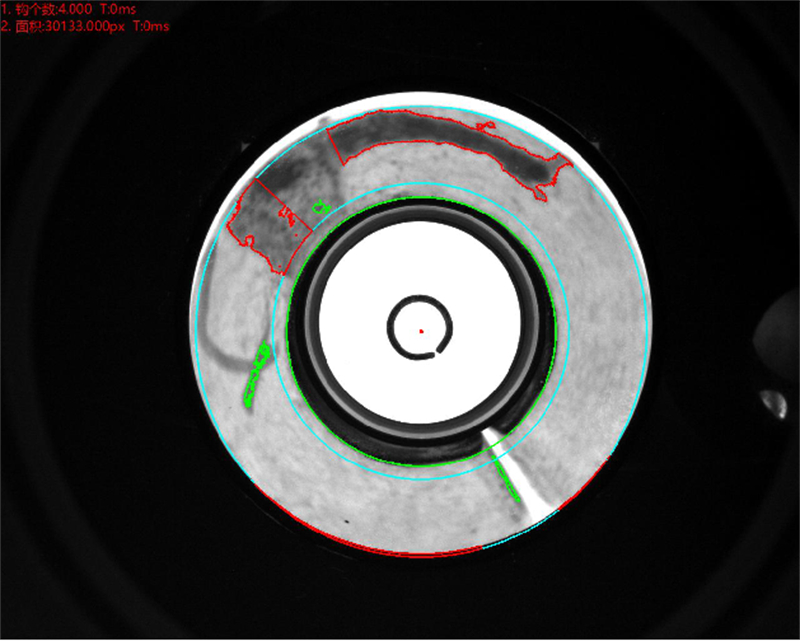

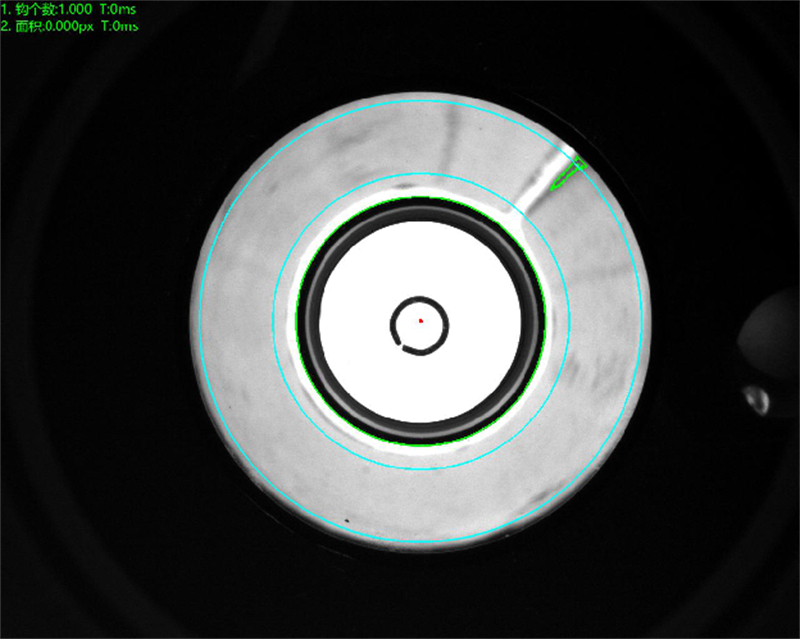

Image of bearing fitting under inspection

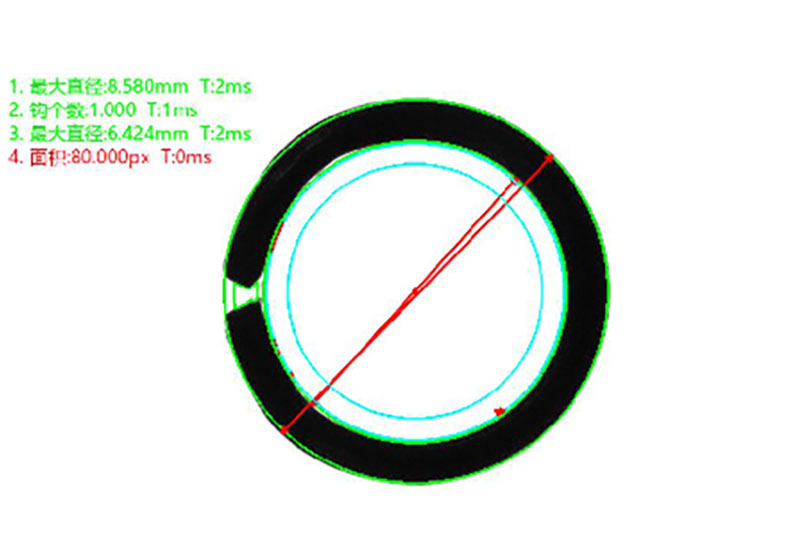

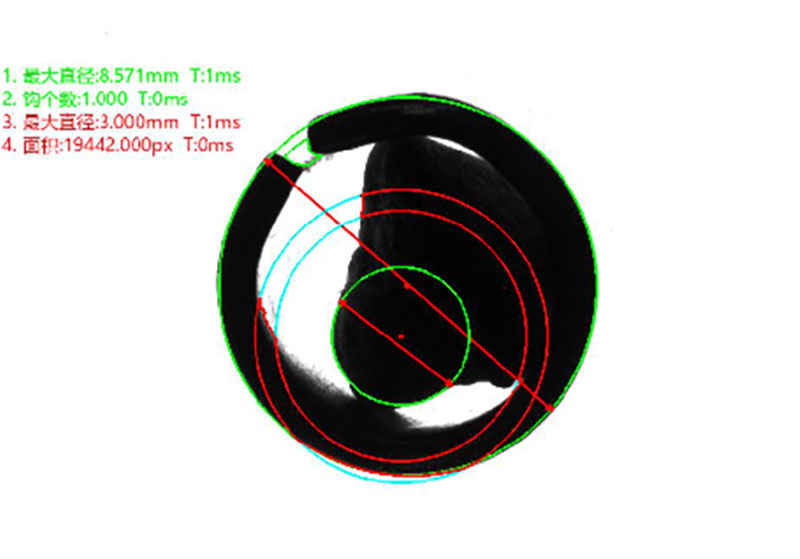

Top side detection

Top backlight detection original image:

Top backlight detection good product analysis image:

Top backlight detection defective product analysis image: NG, cause of defect: inside diameter burr —

Top backlight detection defective product analysis image: NG, cause of defect: foreign matter —

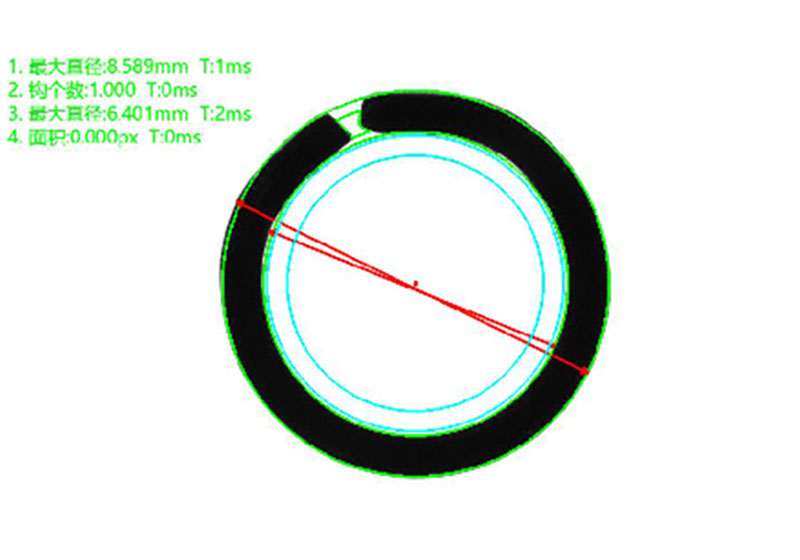

Outer diameter detection

Outer diameter 360° detection original image:

Outer diameter 360° detection defective product image: NG, Cause of defect: Plating fouling —

Outer diameter 360° detection defective product image: NG, Cause of defect: Plating fouling —

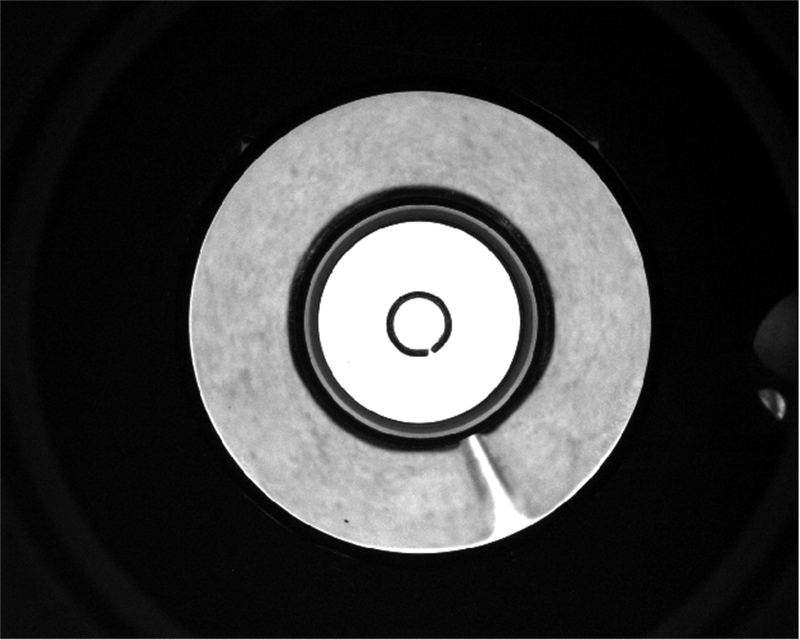

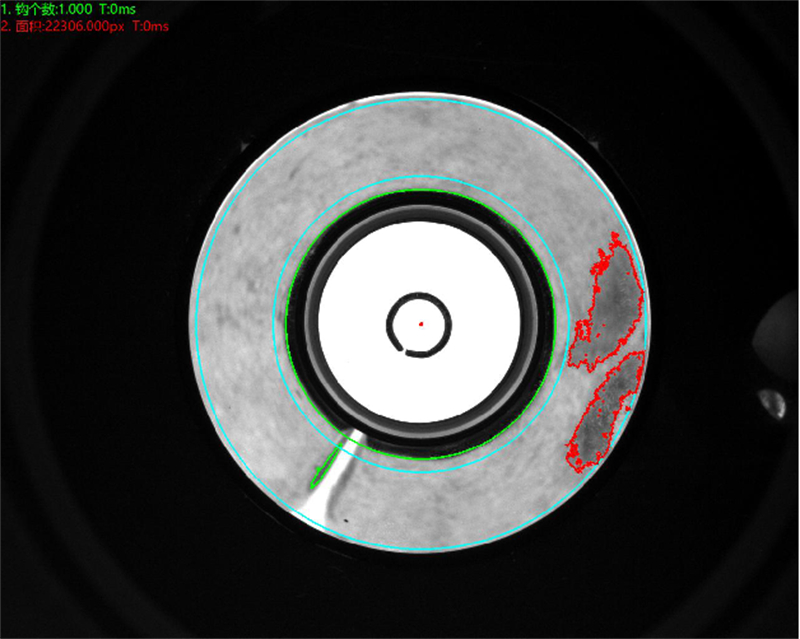

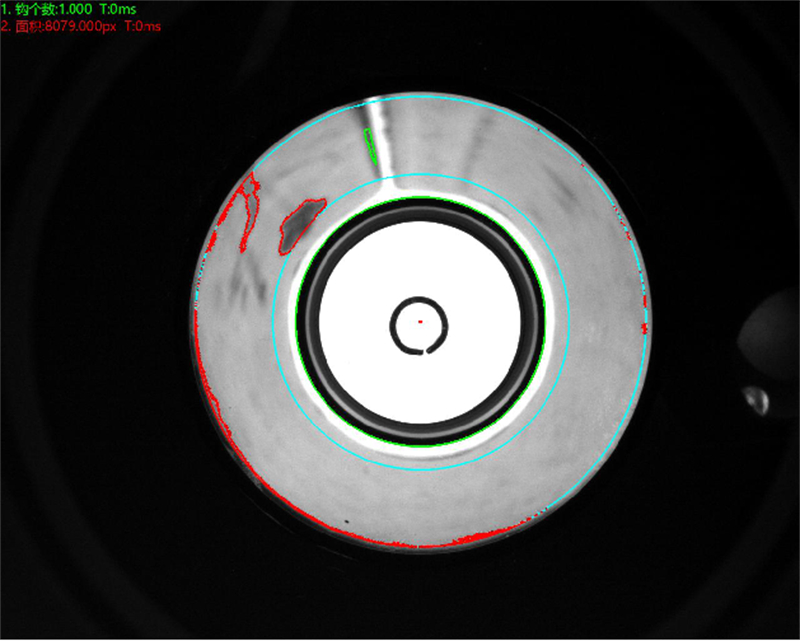

Inner diameter detection

Inner diameter 360° detection good product image: OK

Inner diameter 360° detection defective product image: NG, Cause of defect: Plating fouling —

Inner diameter 360° detection defective product image: NG, Cause of defect: Plating slag —