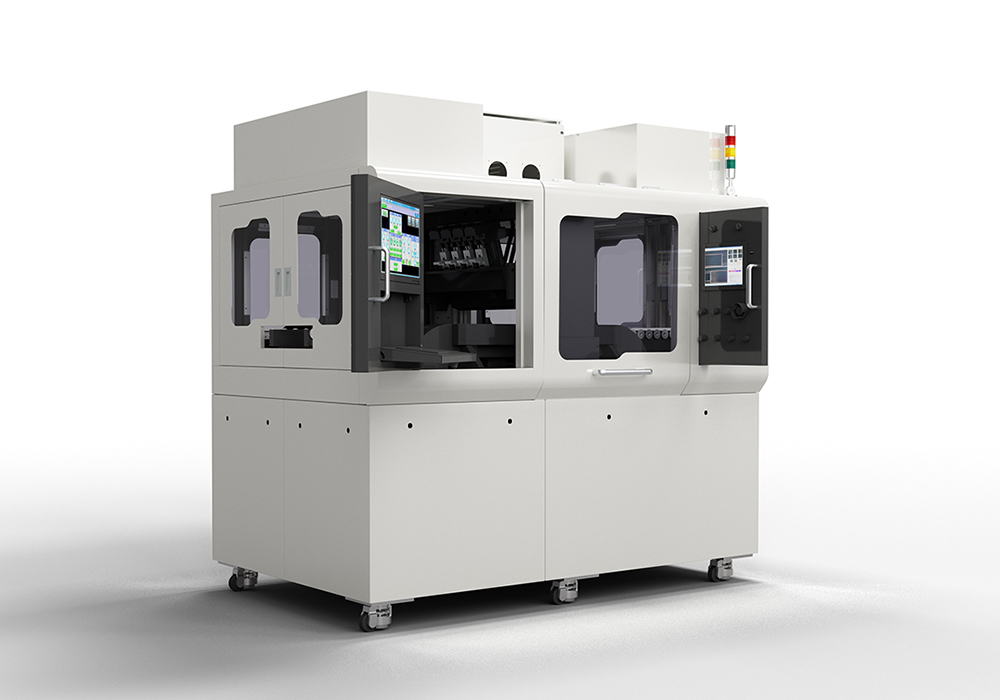

This advanced glass appearance inspection equipment is engineered with a modular design, allowing flexible configuration and scalability. It integrates a variety of imaging techniques and multi-channel image analysis technologies to provide comprehensive coverage during inspections. By leveraging sophisticated AI algorithms, the system achieves high-speed and reliable defect detection, which is critical to maintaining high-quality standards in glass production.

One of the distinguishing features of this equipment is its ability to detect defects not only on the front surface, but also on the back and side edges of the glass. This in-depth inspection capability ensures that no flaws go unnoticed, significantly enhancing the quality control process. As a result, manufacturers can reduce their investment in labour costs, as the need for extensive manual inspections is minimized.

The system addresses several common challenges in the inspection process, such as the high labour costs associated with traditional methods, the complexity of inspecting glass surfaces, and the variability in inspection yields. By automating the inspection process, this equipment helps streamline operations and reduce human error, leading to more consistent results.

In addition, the implementation of this technology not only improves the overall quality of products, but also enhances production efficiency. With faster detection times and more accurate assessments, manufacturers can increase throughput while ensuring that only defect-free glass products reach the market. In summary, this glass appearance inspection equipment represents a significant advance in quality assurance, combining cutting-edge technology with practical solutions to enhance productivity and reduce costs in the manufacturing sector.