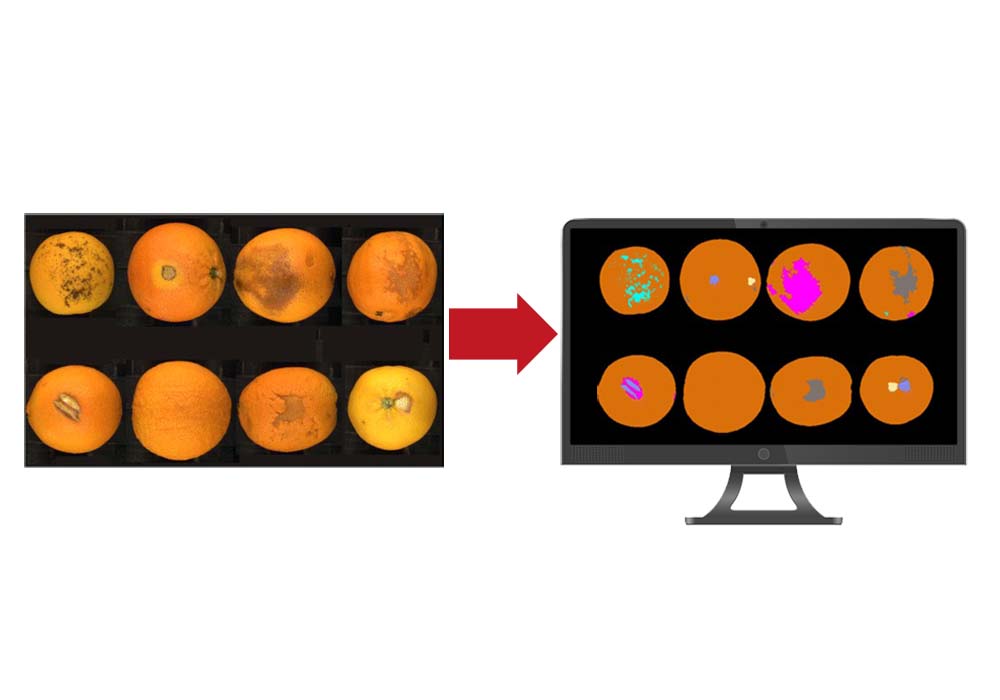

Imagine that your orange farm has just picked a lot of oranges of varying quality. You need to sort these oranges into different piles according to specific attributes and sell them at different prices. What would you do? The traditional way is to hire some workers to inspect oranges one by one, put rotten oranges in one pile, and good oranges in another pile. In a good pile of oranges, pick the small ones into one pile and the big ones into another. But it’s too time-consuming and laborious. If there are multiple subdivision conditions based on appearance, the workload is enormous. I think you need to hire more people to do that. Is there a better way? Of course there is. Use machine vision to do these repetitive tasks. Through the machine vision system, we only need to set the classification conditions, and the machine can help us to inspect and sort oranges, and it will not get tired, work 24/7, and the error rate is much lower than manual visual inspection.