In the ever-evolving world of manufacturing, vision systems have emerged as a transformative technology, revolutionizing the way production processes are performed. These advanced systems leverage the power of machine vision, combining high-resolution cameras, sophisticated algorithms, and data-driven analytics to deliver unprecedented levels of efficiency, quality, and automation.

Here’s how vision systems are transforming the manufacturing landscape:

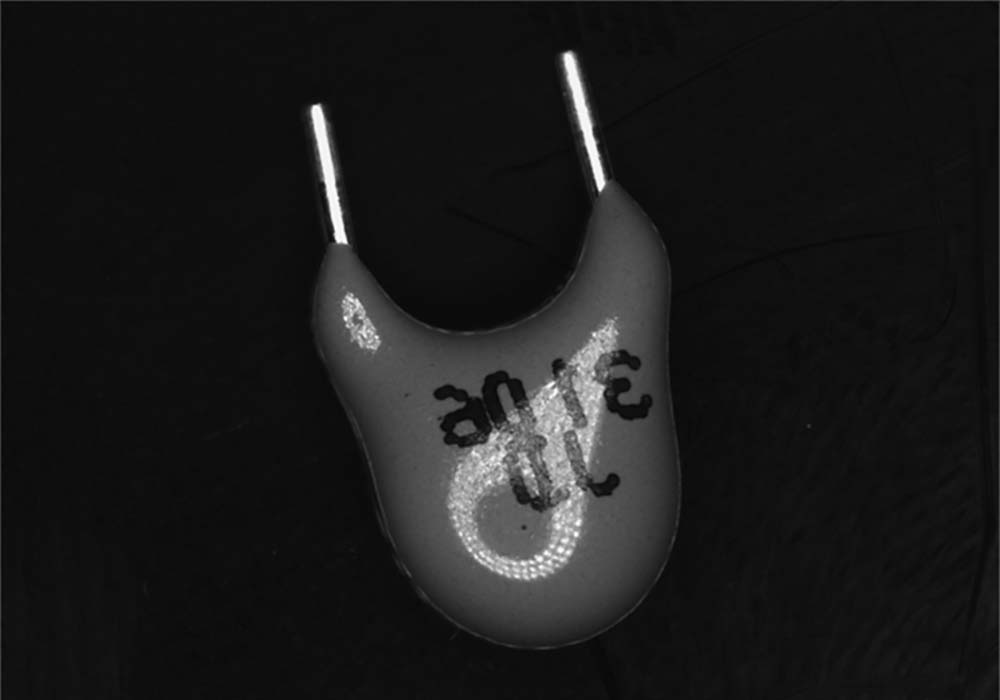

Automated inspection and quality control:

Vision systems excel in real-time defect detection and dimensional measurement across the entire production line. By analyzing high-quality images captured by cameras, these systems can identify a wide range of defects, such as scratches, dents, missing components, or non-conformities, with remarkable accuracy. This automation of the inspection process not only enhances quality assurance, but also reduces the need for manual intervention, resulting in significant time and cost savings.

Intelligent sorting and handling:

Vision systems can be integrated with robotic systems to automate the handling and sorting of manufactured parts. By precisely identifying the location, orientation, and unique characteristics of each component, these systems can guide robotic arms to pick, place, and sort parts with speed and accuracy. This integration of vision and robotics revolutionizes material handling, improving productivity, consistency, and reducing the risk of human error.

Process Monitoring and Optimization:

Vision systems generate vast amounts of production data, which can be leveraged to optimize manufacturing workflows. By analyzing factors such as cycle times, equipment performance, and product quality trends, these systems can identify bottlenecks, predict maintenance requirements, and provide actionable insights to enhance overall equipment effectiveness (OEE) and minimize downtime.

Predictive Maintenance:

Vision systems with advanced analytics capabilities can perform predictive maintenance by detecting early signs of equipment wear or impending failures. By continuously monitoring the condition of machinery and components, these systems can alert operators to potential problems, enabling proactive maintenance and reducing the risk of unplanned downtime.

Adaptive and flexible production:

Vision systems can adapt to changing production requirements, enabling manufacturers to quickly respond to market demands and product changes. By providing real-time feedback and adaptability, these systems can facilitate the production of customized or customized products without compromising efficiency or quality.