AI Appearance Defect Detection Solution for Ceramic Tiles

Common defects in ceramic tile production lines:

Including powder balls, corner cracks, glaze dripping, graph breakage, ink dripping, dirt, edge cracks, missing corners, brick slag, white edges, etc…

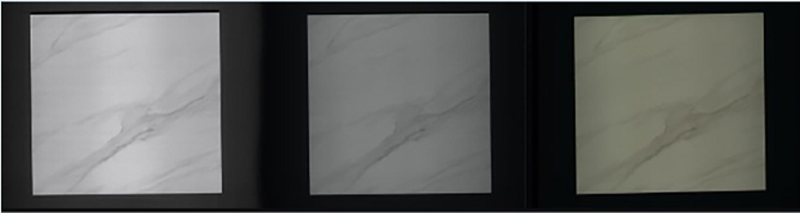

For some defects, three pictures were taken at specific angles for each brick. The shooting conditions for these three pictures are as follows: Pic 1. Black and white picture with low angle lighting, Pic 2. Black and white picture with high angle lighting, Pic 3. Color picture

Difficulties in AI surface defect detection for ceramic tiles:

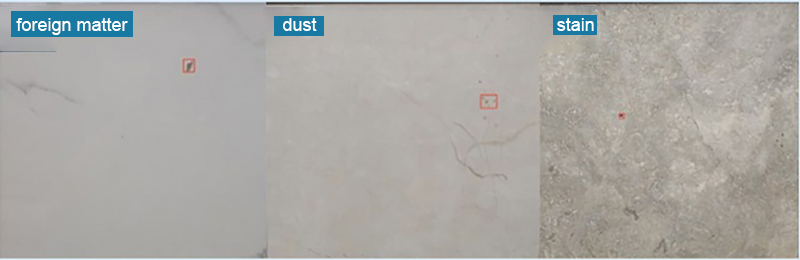

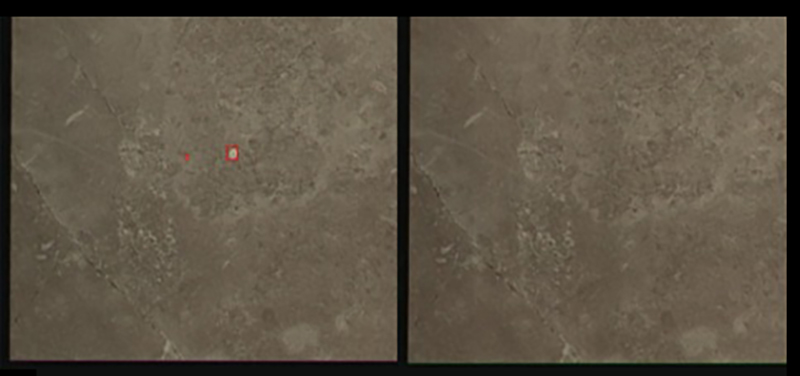

- There are some extremely small defects, only a few pixels.

- The defect characteristics are similar to complex patterns on ceramic tiles.

As shown below:

Ceramic tile AI appearance defect detection small defects

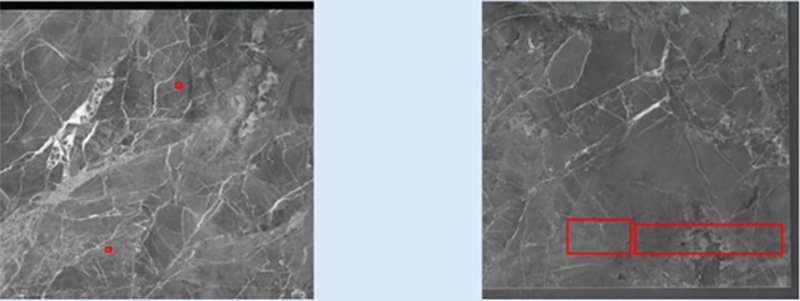

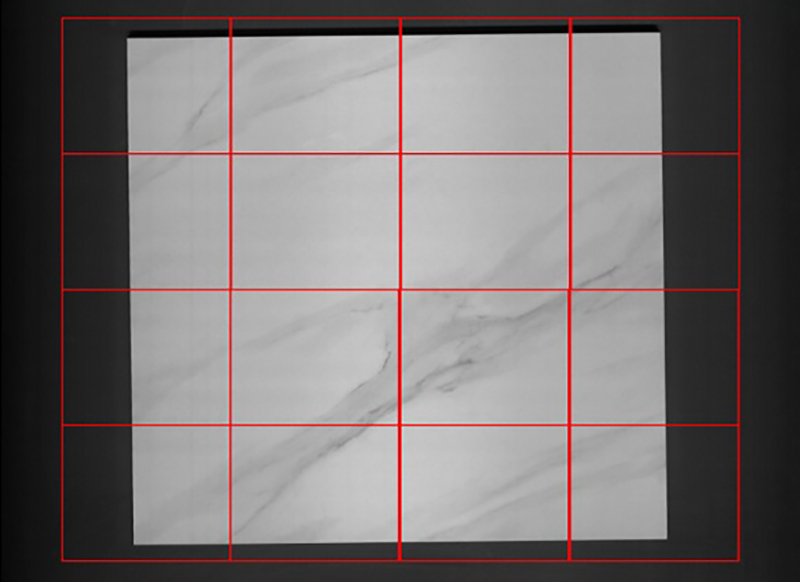

Solution: Perform image segmentation (as shown below)

Disadvantages: Too many segments, recognition speed is slow by about 2-3 seconds

Solution:

- To solve the problem that the complex patterns and defective features of tiles are similar, the Al algorithm is adjusted to increase the samples of complex and defective tiles.

Disadvantages: It is necessary to collect patterns of complex tiles, such as defective pictures, flawless pictures (samples with consistent patterns and flawless colors) and annotated data.

- In the case of fewer samples, defects of other patterns can be transplanted through Photoshop.

Disadvantages: slightly time consuming

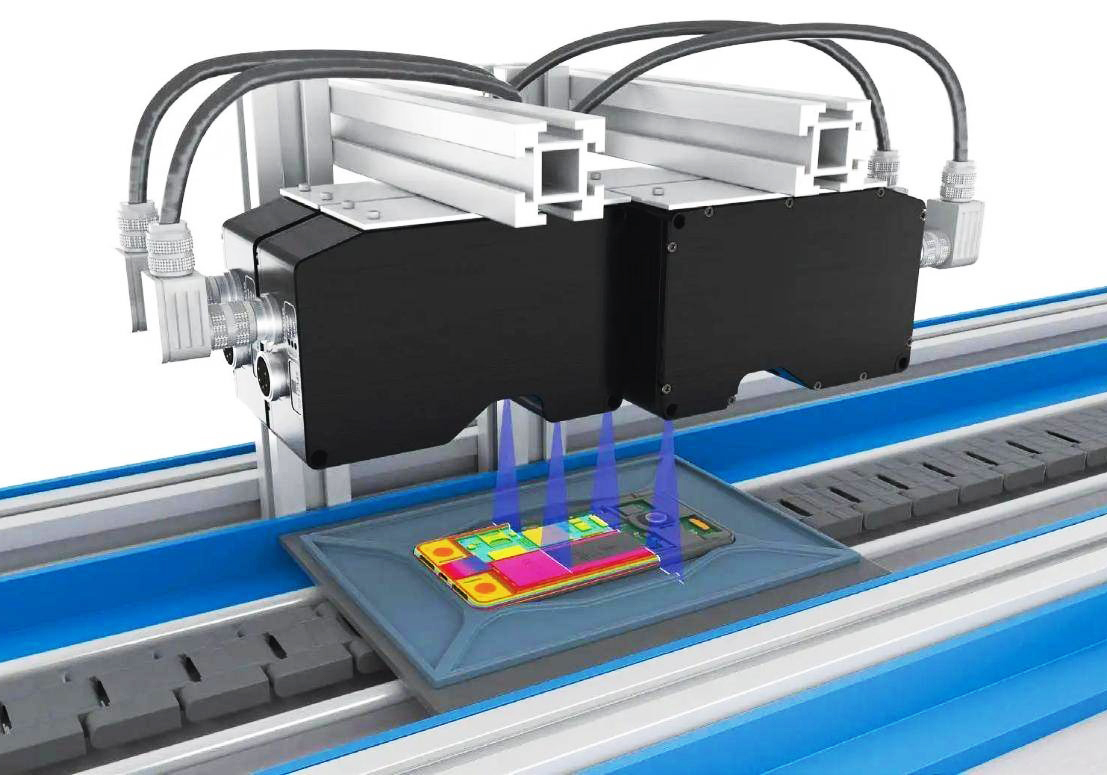

The AI detection system we developed based on deep learning technology can do more, such as: detection of packaging industry, 3C and semiconductor industry, hardware industry, etc.

In the field of machine vision, we have been overcoming difficulties and working on cutting-edge technologies. Some subtle defects, problems that traditional vision cannot do, and problems that the human eye cannot judge at the moment, our AI detection system can completely solve these problems.