LCD screens are composed of several layers, including the liquid crystal layer, polarizers, color filters, and thin film transistors. Defects can occur in any of these layers during the manufacturing process, which can lead to problems such as dead pixels, color variations, and uneven luminance.

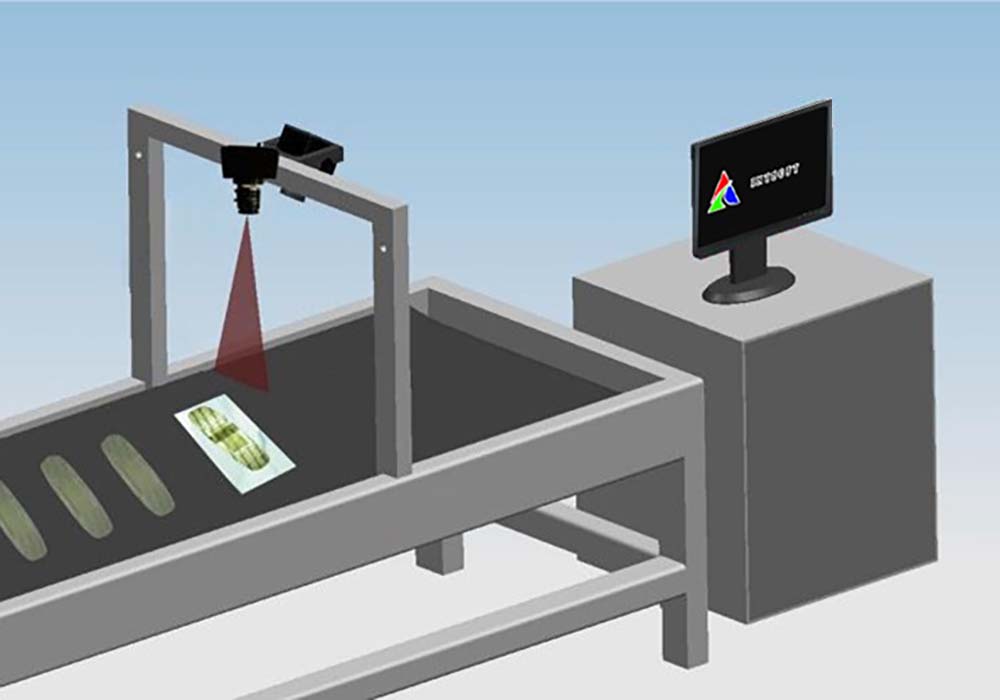

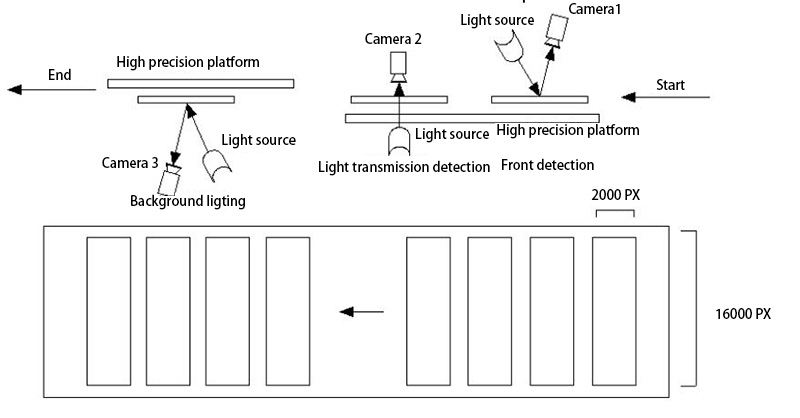

Machine vision systems can be used to automate the inspection of LCD panels and detect these types of defects. The typical approach involves using high-resolution cameras to capture images of the LCD panel, which are then analyzed using computer vision algorithms.

Machine vision detection diagram:

Follwing is Intsoft Technology machine vision defect detection case study, for archiving and sharing.

Detection Purpose:

For LCD screen smudge scratch quality inspection, alternative to the original manual inspection method for LCD screen quality inspection, to determine whether the surface of the LCD screen has a foreign matter, scratches, different colors, bulge, dents, pinholes, burrs, bright spots.

Detection Method:

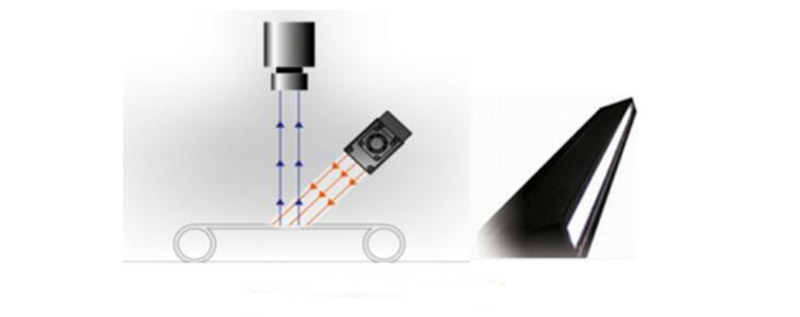

As shown in Figure 1, a line array camera is used to set up the LCD screen on the motion platform for quality inspection to detect foreign objects, scratches, different colors, bumps, dents, pinholes, burrs, and bright spots on the LCD screen.

Machine vision inspection process design:

1. Open the product to 180° and place the LCD screen horizontally on the carrier table.

2. The carrier table moves and the camera starts to collect images.

3. After the collection is completed, reset the carrier table.

4. Detection software: Analyze the quality of LCD screens.

5. Based on the analysis results to give the product an OK, NG judgment.

6. Operator: According to the results of the above detection, proceed with the bin operation or re-inspection operation.

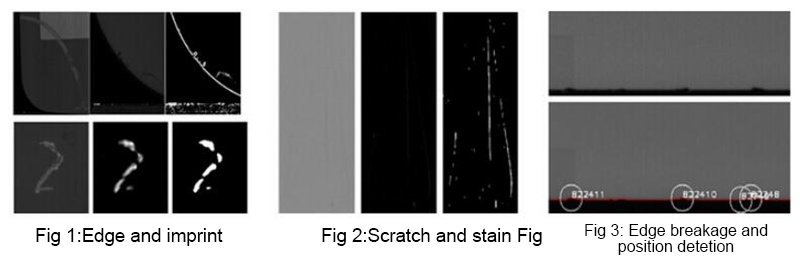

Principle of Visual Inspection Algorithm for LCD Screen Scratches and Stains.

Defective type

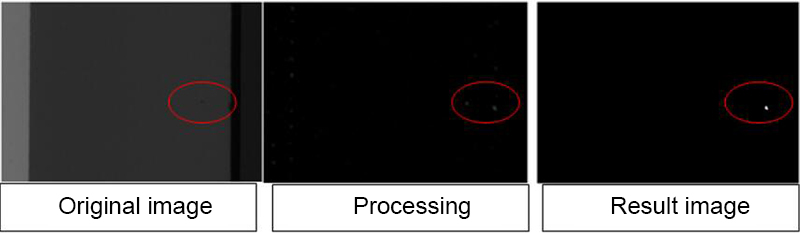

1. Visual Detection Abnormalities – Black Spots

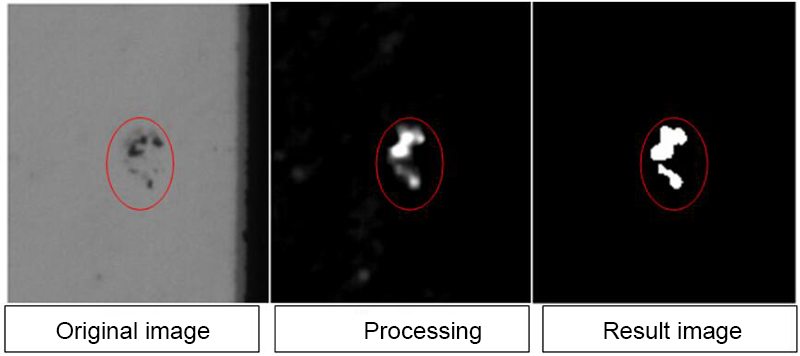

2. Visual Detection Abnormalities – Foreign matter

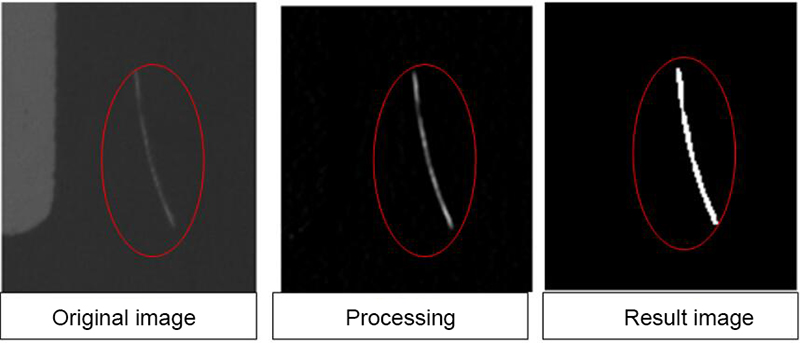

3. Visual Detection Abnormalities – Scratch

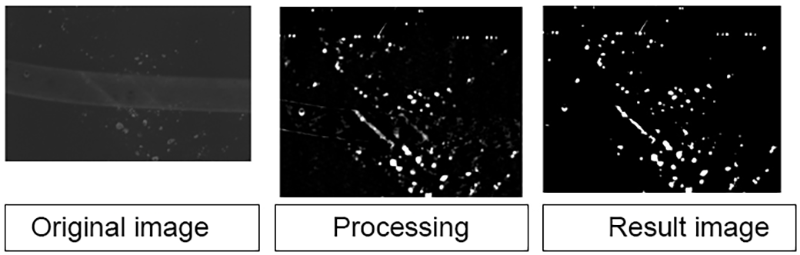

4. Visual Detection Abnormalities – Bubble

5. Visual Detection Abnormalities – Foreign matter

Conclusion

Scratches, smudges, edges, marks, chipping defect localization detection, contour tracing and analysis, 3 pixel depth detectable