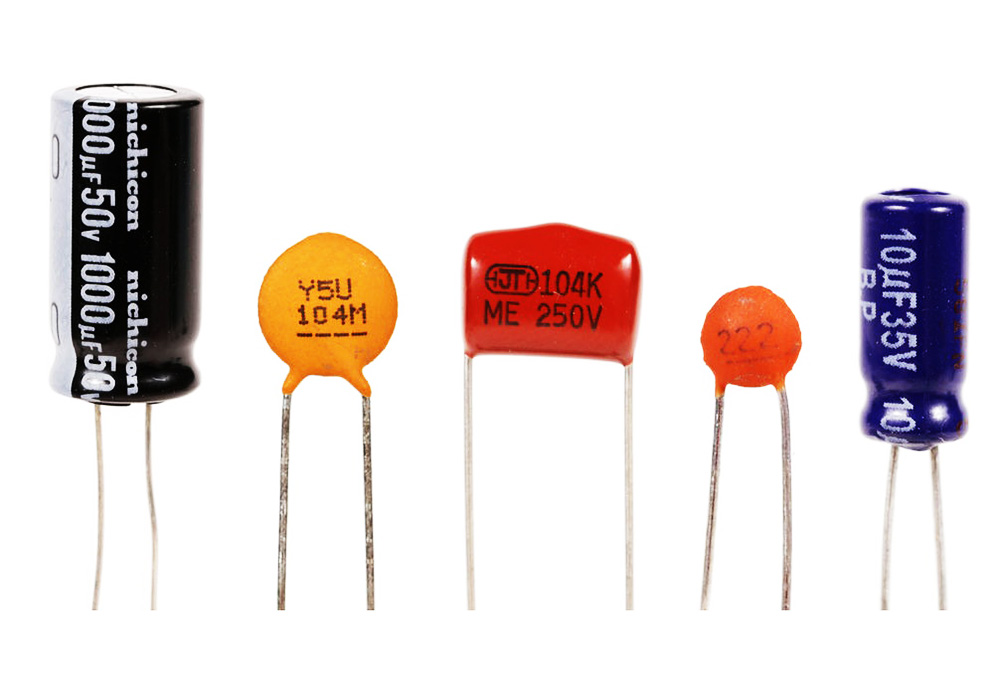

Capacitor is a small part, but has a large market, whether it is a small 3C consumer electronics products, or household appliances, all need to use capacitors. Capacitor quality control, related to the use of capacitors to the quality of each electronic device, for the production of electronic devices for the enterprise, capacitors before factory detection is crucial.

Capacitors in the production process, if the product is detected manually, then the need for labor is also greater. There are pain points such as missed detection, incorrect detection, low speed, etc. After all, the human eye will always have fatigue.

In response to this situation, Intsoft Technology in-depth understanding of the process needs of the industry, combined with our many years of machine vision inspection technology precipitation, research out of capacitor appearance defect detection equipment.

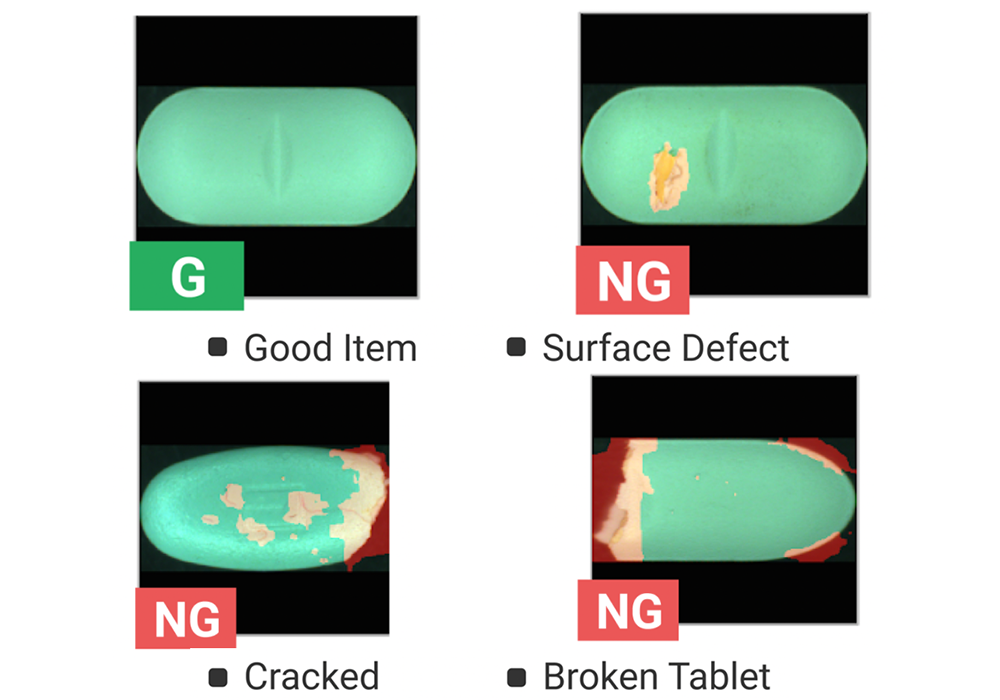

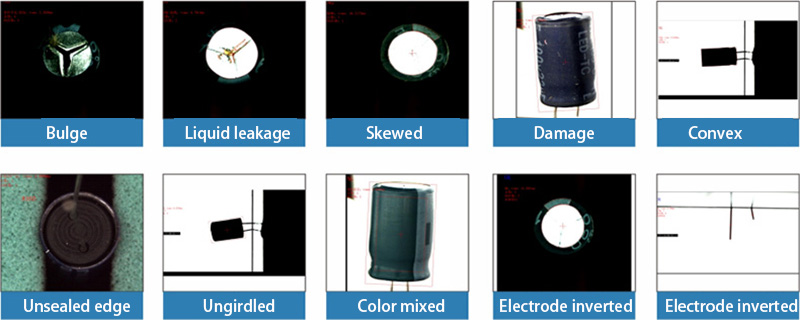

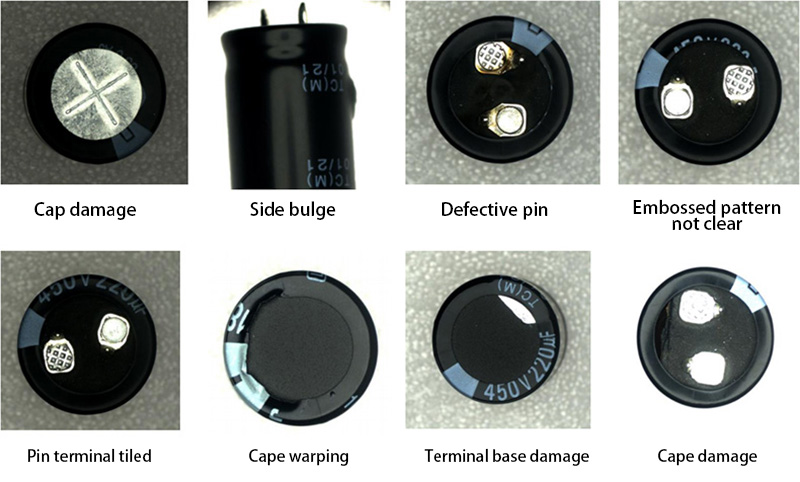

Defective product

Principle of appearance detection equipment for capacitors

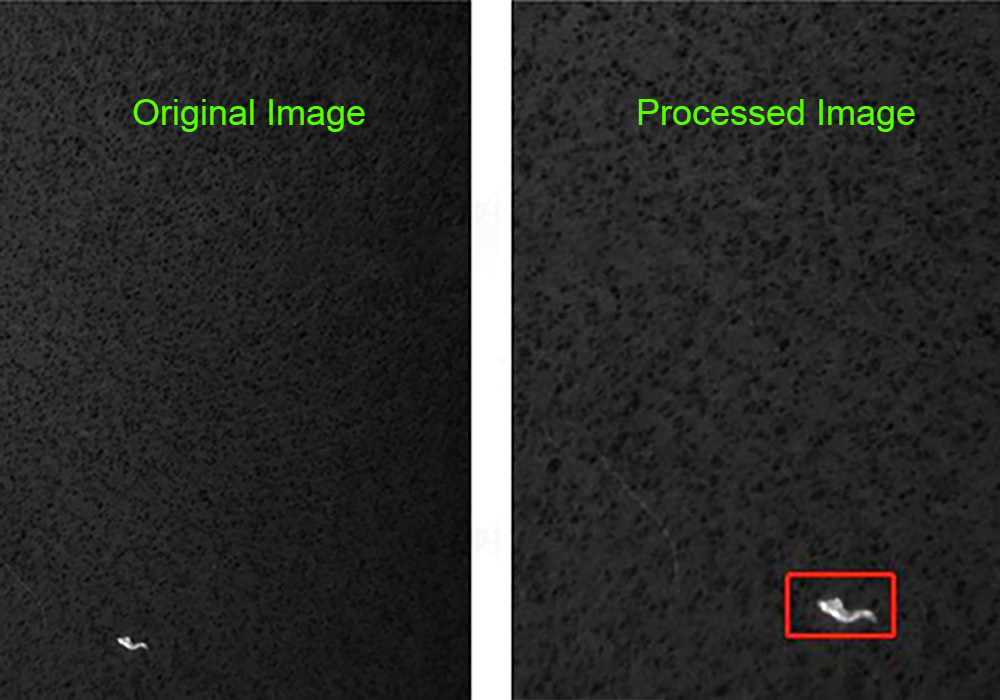

Capacitor appearance detection equipment, which is based on machine vision system detection equipment, is also automated detection equipment. Capacitance inspection equipment is the principle of the use of visual inspection system, through the CCD industrial camera will be taken into the target into image signals, transmitted to the special image processing system, according to the distribution of pixels and brightness and other information, converted into digital signals. The imaging system performs various operations on these signals to extract the characteristics of the target, and then based on the results of the judgment, the equipment operation on site is controlled to perform visual inspection, dimension measurement, defect detection and system positioning.

It can replace traditional manual inspection and realize on-line high-speed automated inspection of the appearance of industrial products.

Through the capacitive appearance detection equipment, we can realize various defects in high-speed detection of capacitive appearance, such as color changes, unclear printing and other detection.

Advantage of intsoft capacitor appearance machine vision detection equipment

Accuracy and consistency: Machine vision systems can inspect capacitors with a high degree of accuracy and repeatability, identifying even minor defects that may be missed by the human eye.

Speed and Throughput: Automated machine vision inspections can be performed much faster than manual visual inspections, allowing for higher throughput and shorter production cycles.

24/7 Operation: Machine vision systems can operate continuously without fatigue or distraction factors that can impact human inspectors during long shifts.

Data Capture and Analytics: Vision systems capture detailed inspection data that can be analyzed to identify trends, optimize processes, and improve quality control.

Flexibility: Machine vision solutions can be programmed to inspect a wide variety of capacitor sizes, shapes, and styles, adapting to changing production requirements.

Traceability: Comprehensive inspection records are automatically generated, providing full traceability for quality assurance and compliance purposes.

Cost savings: Automating visual inspection can significantly reduce labor costs and improve productivity, leading to overall reductions in manufacturing costs.

Proactive Maintenance: Some machine vision systems can detect subtle changes in capacitor appearance that may indicate the need for equipment maintenance or adjustments, enabling proactive interventions.