Carbon fiber felt has many excellent properties, such as light weight, high specific strength, good electrical conductivity, fast penetration speed, uniform fiber distribution, special corrosion resistance, high temperature resistance, fatigue resistance, thermal conductivity and far infrared radiation. It can be widely used in chemical anticorrosion, aviation, aerospace, sports equipment and other fields. It has been widely used in building structure reinforcement, adsorption purification, thermal insulation materials, and automobile manufacturing.

Since carbon filber is often used in aviation, construction, anti-corrosion engineering, etc., if there is a quality problem, it will have a great impact. Therefore, carbon felt must also undergo strict testing before leaving the factory.

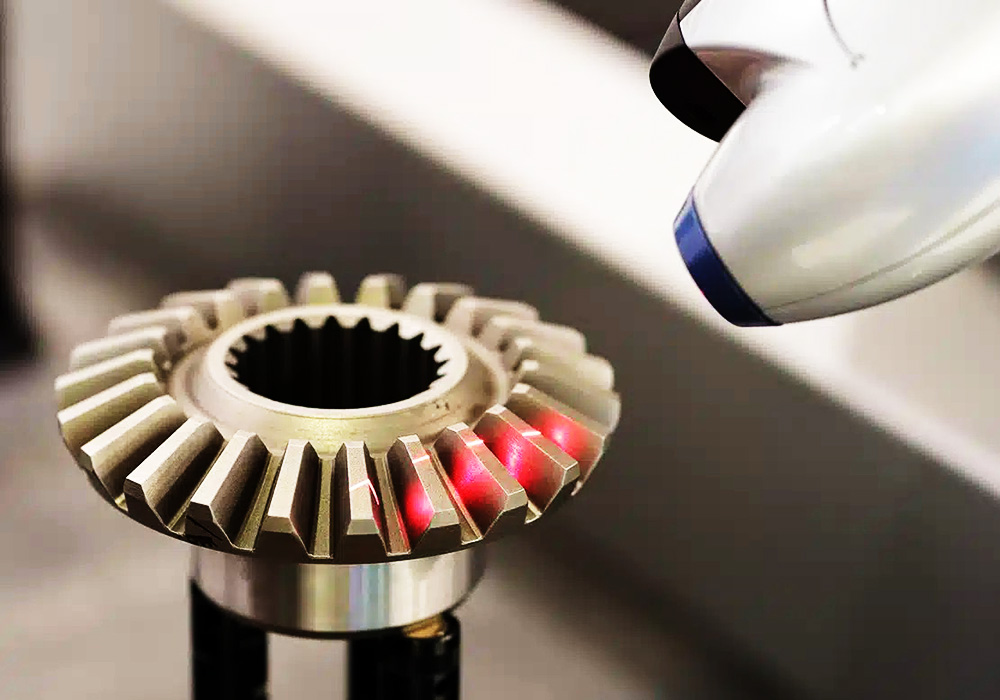

The following is the working process for carbon defect detection equipment designed by Intsoft Technology for customers.

Visual inspection items:

Coil and sheet: Visual hardware and software are universal

Workflow:

- Enter basic product information, take OK products for modeling, and set test data.

- Install the camera at a fixed position, and the product moves with the test platform. When it reaches the position of the photoelectric sensor, a trigger signal will be generated immediately, and the camera will take pictures and upload them to the database.

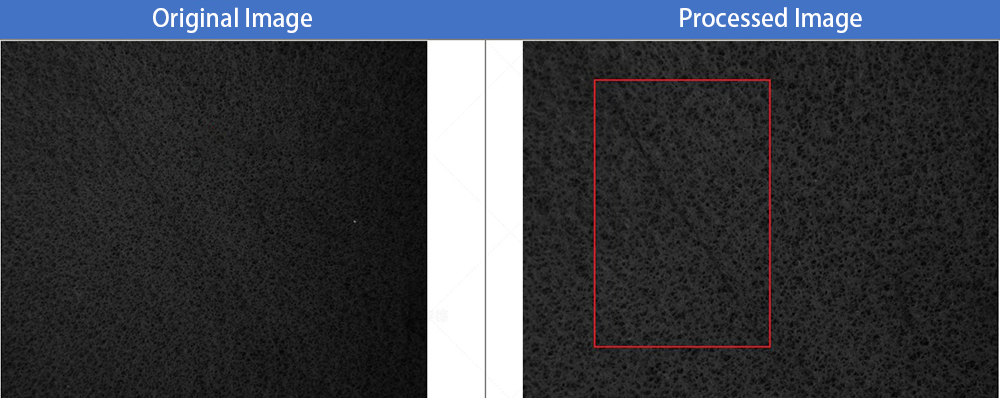

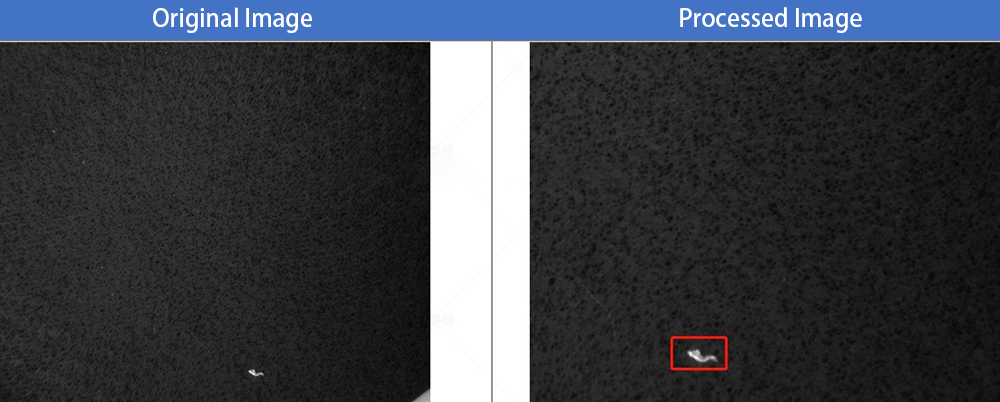

- After receiving the image information, Intsoft Technology visual recognition system will perform a series of processing, analysis, and good/bad product judgments, and the interface will output the test information in real time. If the product is detected to be inconsistent with the preset data, an NG signal will be output; if the test is OK, the product will enter the next process according to the customer’s requirements.

- According to the preset parameters, product test judgments are made, and test parameters can be set in different areas to flexibly respond to different test requirements of different areas of the same product.

Process

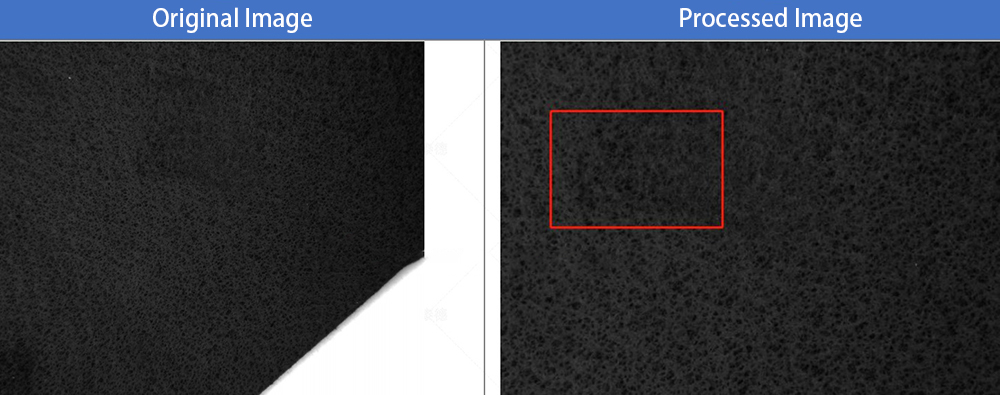

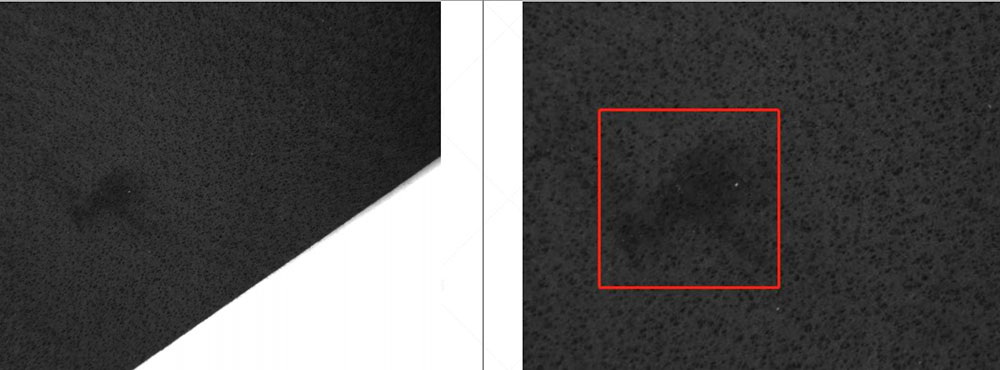

Scratches: They are all black, so it is difficult to extract these defects. AI is needed.

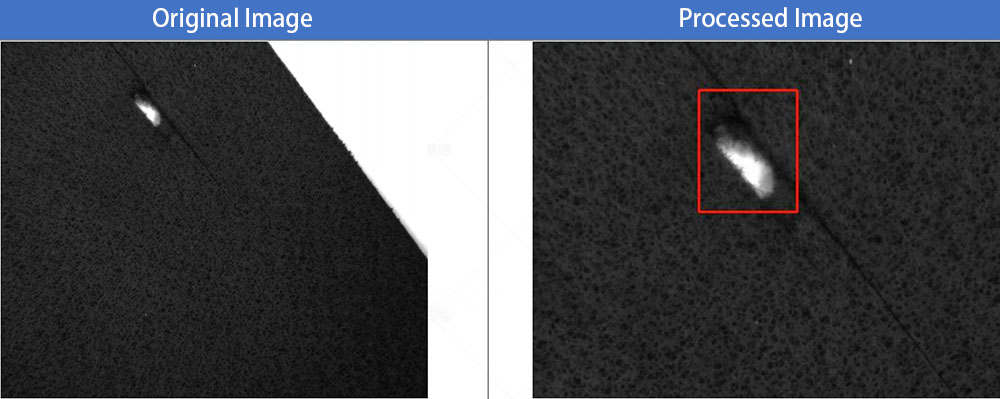

Foreign matter

Dirt: They are all black, so it is difficult to extract this type of defect, AI is needed

Broken hole

System functions:

- 1. When the system detects a defect, it outputs an alarm signal.

- 2. Real-time information display and record detection information.

- 3. Provide special tools such as system parameter adjustment and image saving. The system interface is friendly, operable and intuitive.

- 4. In order to ensure the security of data, the system is equipped with permission management. Only administrators with permission can modify the corresponding system parameters.

- 5. According to the selected product inspection items, matching the inspection program, the inspection area can be adjusted according to the actual situation.

- 6. The inspection history records can be automatically counted, saved, queried, called and other functions.