Visual inspection items: upper and lower end faces of double-layer metal rings, 360-degree inspection of the outside and inside, shrinkage porosity, debonding at the opening, missing parts of the edge, defects of the flash-plated end face, insufficient roundness of outer circle holes and other defects.

Workflow:

- Enter basic product information, model OK products, collect images for preprocessing, extract key feature points of images that meet algorithm requirements, and establish image data sets.

- Four cameras are installed in fixed positions. When the product reaches the inspection position, a trigger signal will be generated immediately. The camera collects images and uploads them to the database.

- The collected images are processed by Intsoft Technology’s intelligent image processing algorithm to judge good/bad products, and the interface outputs inspection information in real time. If the product is detected to be inconsistent with the preset data, the NG/OK signal is output.

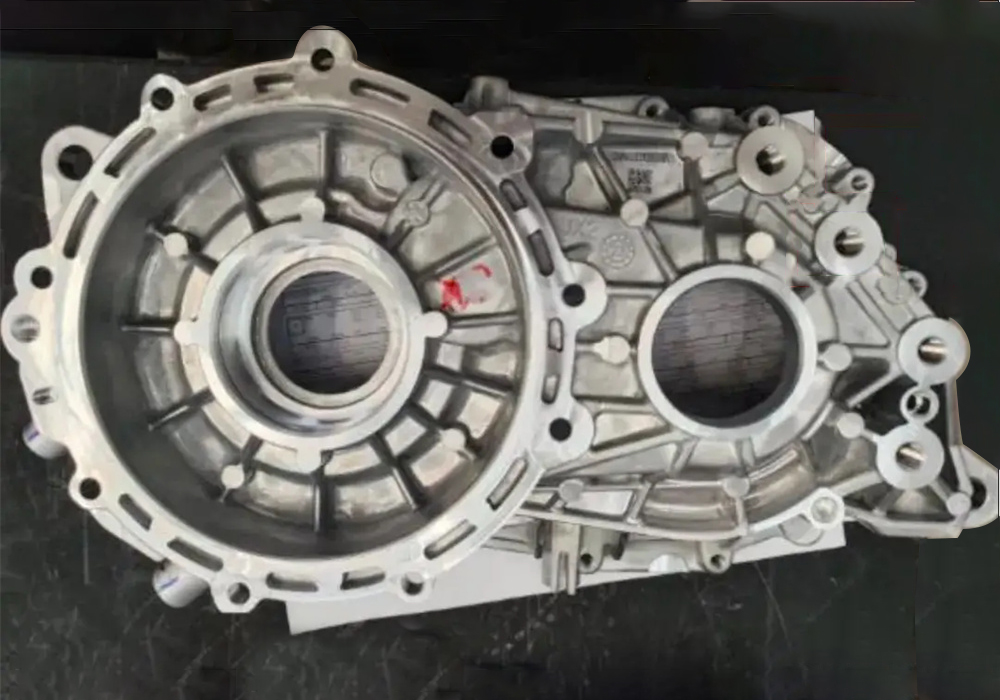

Image acquisition:

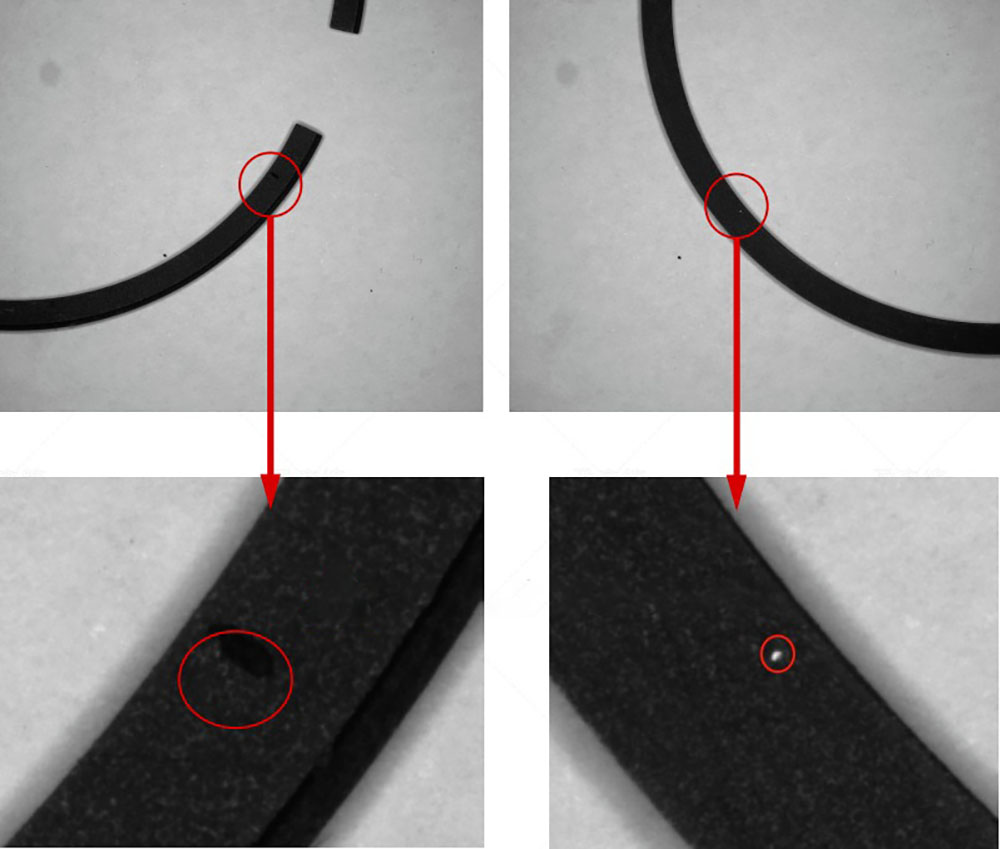

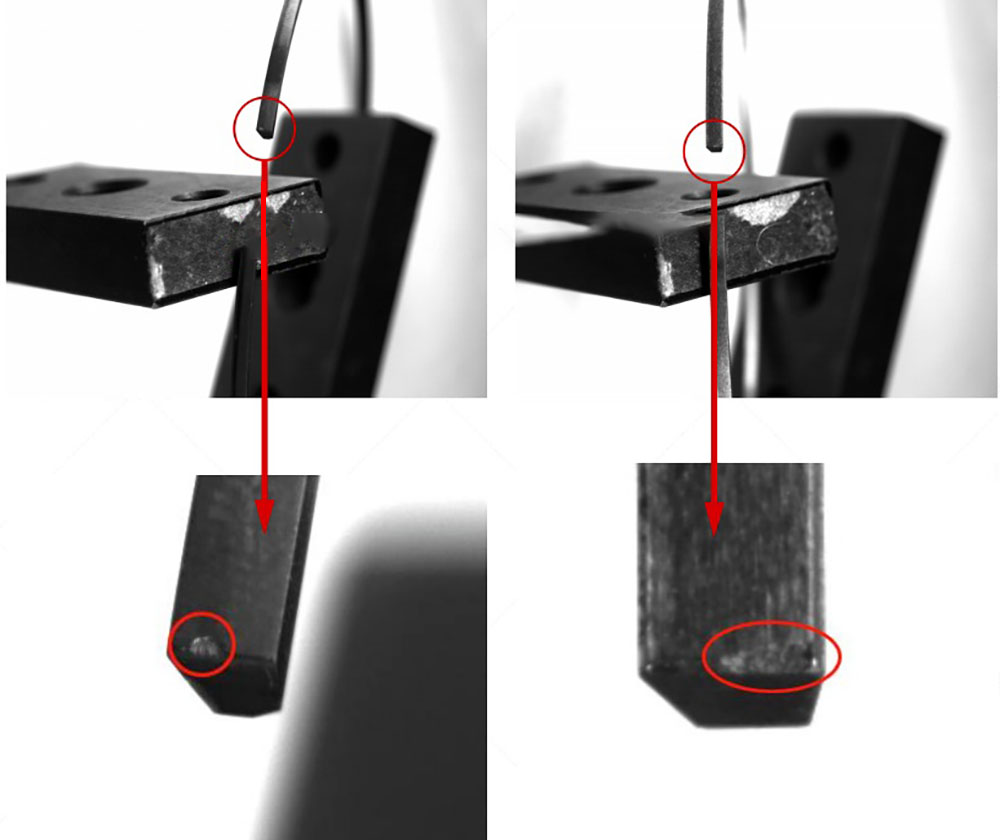

Shrinkage porosity on end surface:

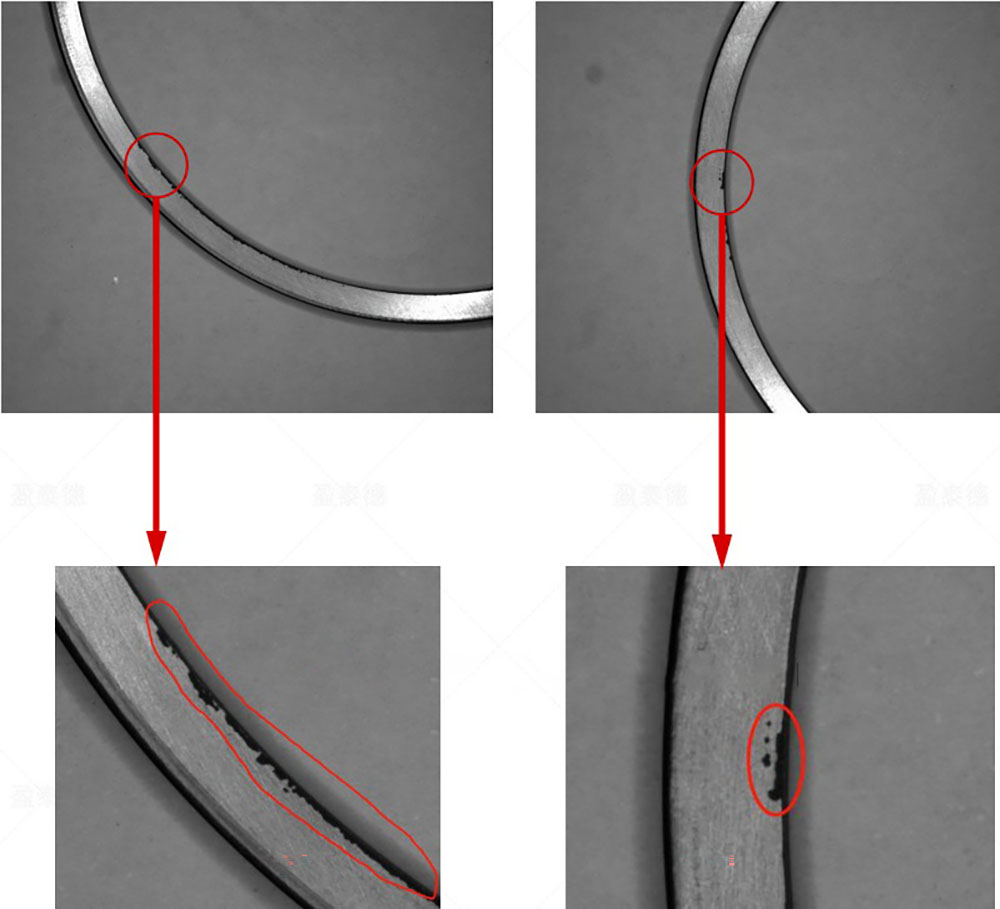

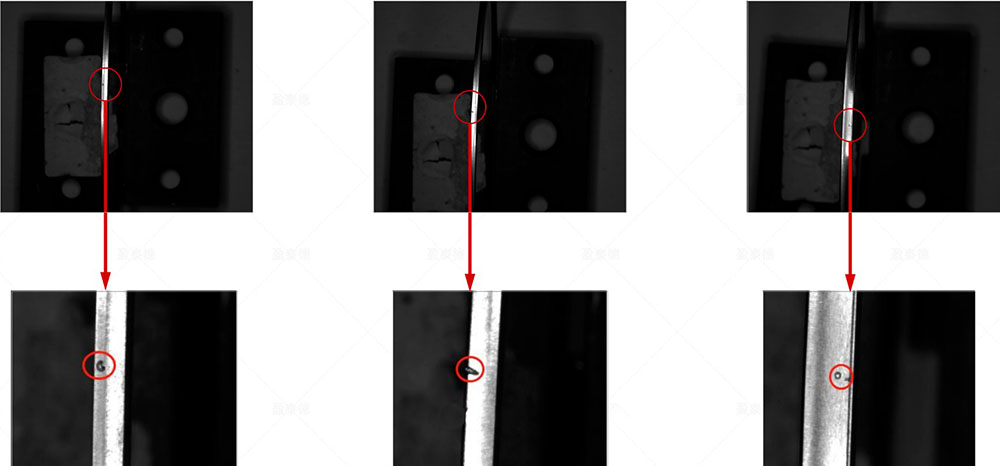

opening is separated:

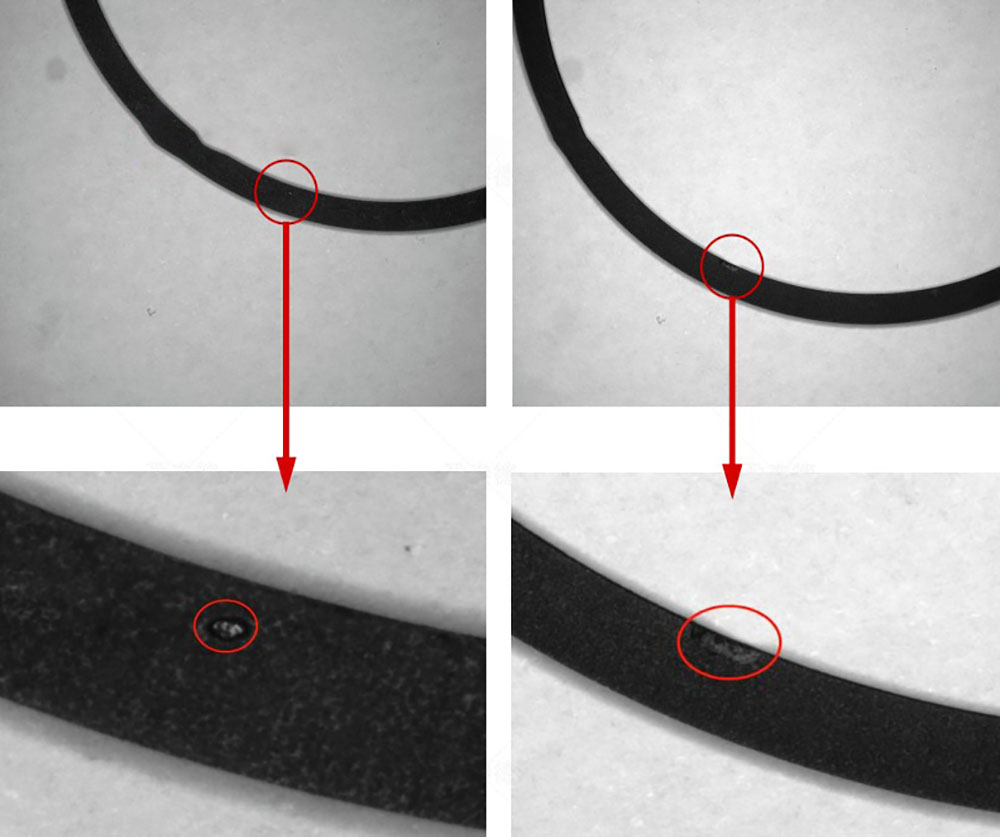

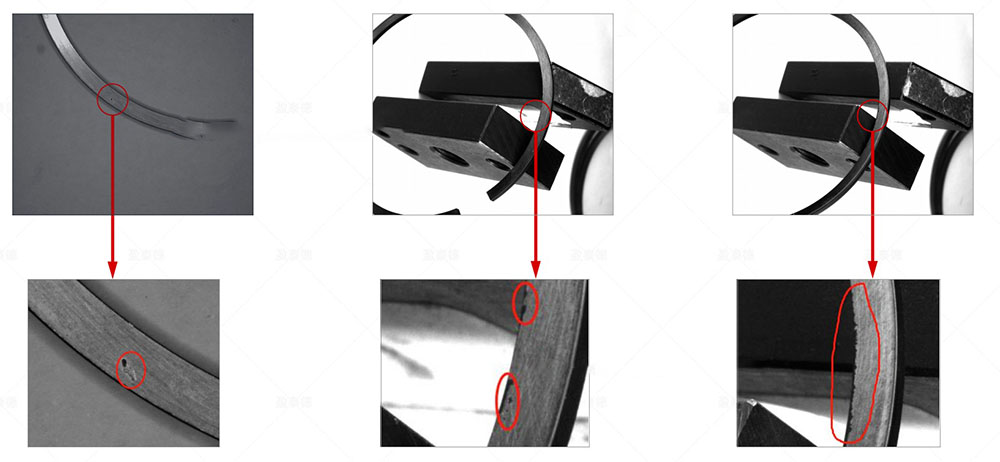

Missing parts of the edge:

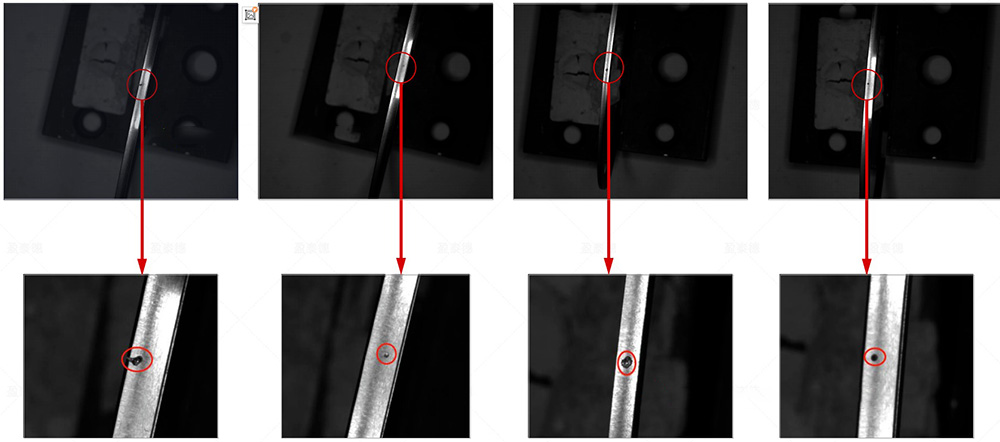

Flash plating missing:

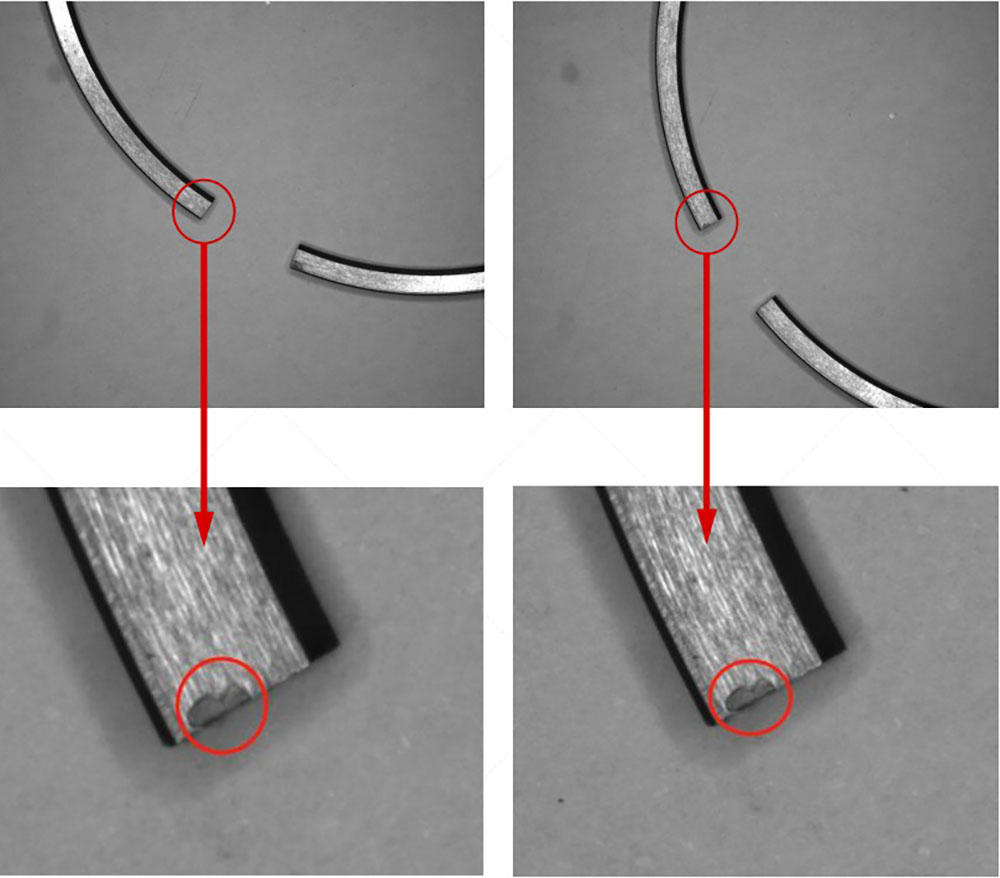

Outer circle has cavities:

In the solution above, the visual system needs to cooperate with the PLC controller to complete the photo taking and system detection operations, and transmit the results to the PLC controller.

System functions:

- When the system detects a defect, it outputs an alarm signal.

- Real-time information display and record detection information.

- Provide special tools such as system parameter adjustment and image saving. The system interface is friendly, operable and intuitive.

- In order to ensure data security, the system is equipped with permission management. Only administrators with permission can modify the corresponding system parameters.

- According to the selected product inspection items, matching the inspection program, the inspection area can be adjusted according to the actual situation.

- The inspection history records can be automatically counted, saved, queried, called and other functions.