As a popular fast food, quality control of instant noodles is particularly important. Common defects of instant noodles are as follows:

1. Shape defects: such as wrinkles, deformation, breakage, etc., which affect appearance.

2. Color defects: such as fading and uneven color caused by overcooking.

3. Impurity detection: such as the mixing of foreign matter such as hair and plastic, which affects health and safety.

4. Dimensional deviation: such as length, width, and roundness do not meet the standards and are difficult to put into the packaging bag

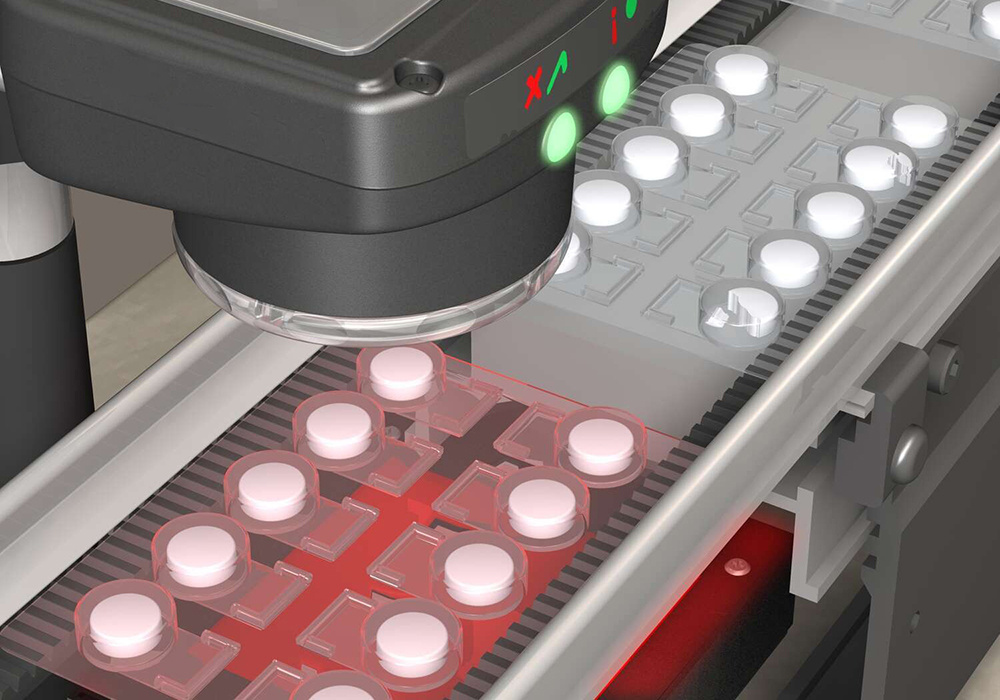

In order to avoid quality problems with instant noodles and damage the health of the vast number of people who eat them, defect detection of instant noodles is a key point in production. Through machine vision technology, companies can quickly and accurately inspect the appearance of instant noodles. At the same time, the inspection system can also generate detailed defect data and use it as data for AI deep learning to further improve the speed and accuracy of subsequent product inspections.

Following is the case study video shared from Intsoft Tech

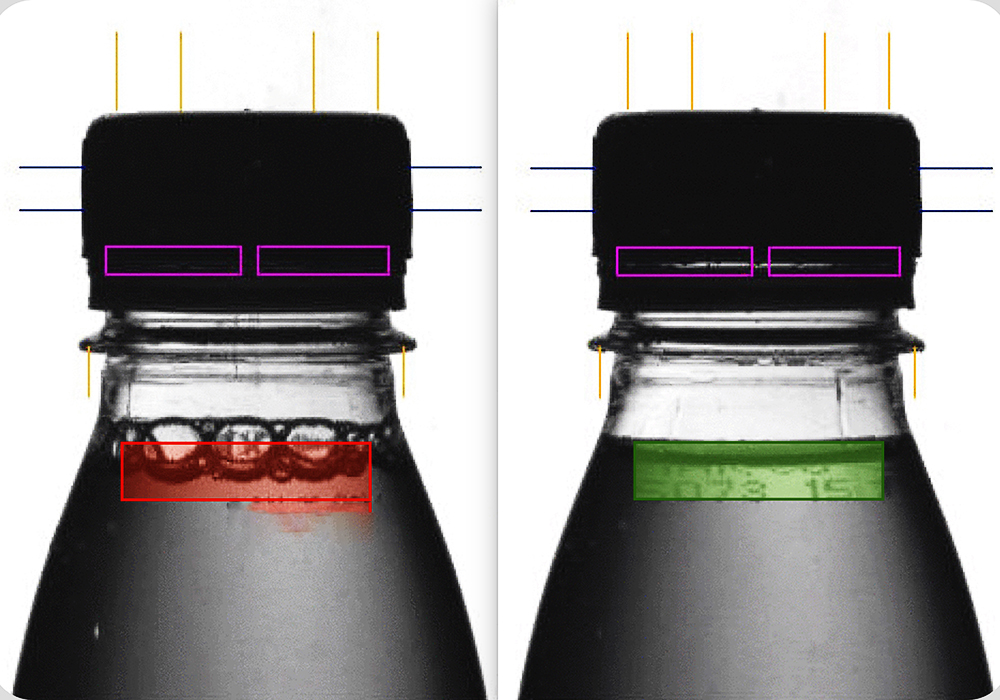

Different properties of instant noodle pieces can be detected, such as whether the pasta pieces are raw or cooked:

Normal detection speed, hundreds of pieces can be detected per minite:

Intsoft Tech’s intelligent defect detection system based on deep learning has established an accurate recognition model for various defects through training with a large number of instant noodles samples. Through high-speed scanning by industrial cameras, the information of each instant noodle on the surface of the instant noodles piece can be captured and compared with the trained standard model to instantly determine whether the product has deformation, color difference, impurities and other problems. Compared to traditional programming methods, deep learning algorithms can learn autonomously and continuously optimize recognition capabilities, greatly improving detection accuracy and adaptability.