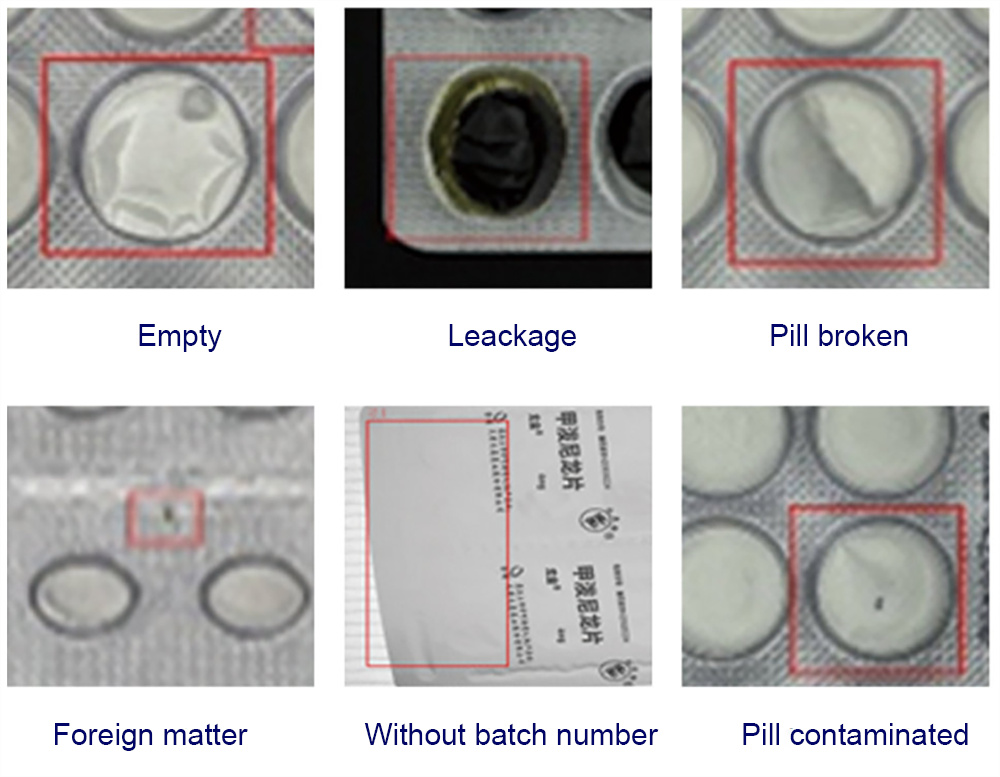

At present, the main defects of the aluminum foil blister are hollow reticulation, cracks, foreign matter in the blister plate, stacked pieces, empty bubbles, fragments, repetition of product batch number printing, missing printing, broken frame, leakage of metal edges of the aluminum foil, and other defects. Most defects are caused by unstable processes.

Common defects and defect manager

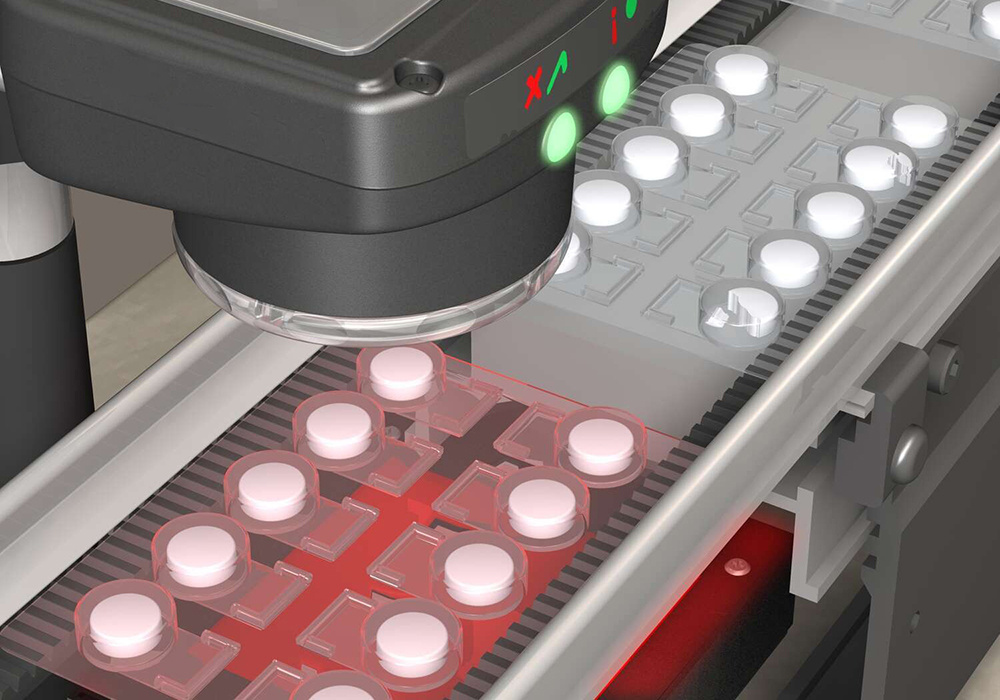

1. Appearance detection

Visual inspection equipment using Intsoft’s own algorithm allows a complete inspection of the product. The equipment has a defective product record function that can record information about defects in the batch of products and facilitate data traceability. Through the line array camera to recognize defects such as bumps, scratches, black spots, etc., then the machine will be trained and improve the recognition ability, so that the accuracy and detection efficiency are greatly improved.

2. Dimension measurement

Abnormal sizes of tablets and packages often occur during the production process. Through the industrial camera, this machine detects tablets and packages to determine if they are the same as the preset size. If an abnormal product size is detected, it will be recorded and the corresponding signal will be output as set.

3. Character recognized

Aluminum blister packages are printed with the date, lot number and other information after the tablets are wrapped. Due to production errors, there are occasional defects such as missed prints, printing errors, blurred fonts, and incorrect print positions. When the tablet passes through the machine’s OCR industrial camera, the fonts on the package are recognized and compared with the correct fonts prepared in advance, and specific algorithms and settings are used to judge it and perform the corresponding operations.

4. Sorting

After loading the robotic arm, the machine will issue the appropriate instructions to the robotic arm according to the judgment of the inspected product, and the tablets entering the operating area of the robotic arm will be sorted into the designated area.