Tablet Defect Detection

tablet defect detection is a key part of the tablet production process, and its detection results directly affect the quality of drugs. Common manual inspection methods: high cost, low efficiency, prone to error detection and missing detection, etc., can not meet the requirements of modern enterprises on product quality. Machine vision inspection is widely used in the pharmaceutical industry due to its high degree of automation, low cost, high efficiency and other characteristics.

Machine vision detection program

The following case is from Intsoft Tech’s sharing, which talks about the captured image and software processing of the tablet defect detection solution. The images captured by the industrial camera are sequentially processed by intelligent vision software to identify defective and dirty tablets through absolute difference operation, hit-or-miss operation, binary chipping detection, and image preprocessing.

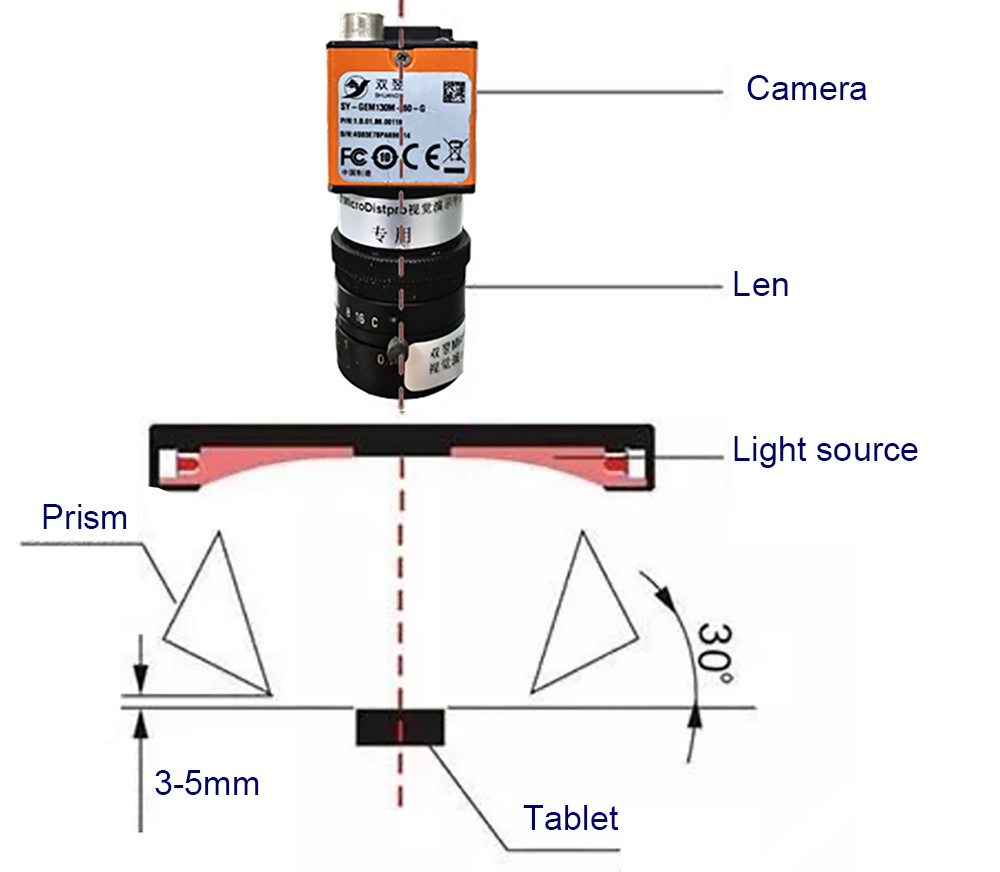

Visual Inspection Hardware System

Because the tablet surface is curved, detection requires uniform light across the entire field of view and the ability to detect dirt and defects on the tablet surface. A symmetrical, spherically distributed shadowless light source is used. This light source uses a special diffuse plate to scatter light in different directions, forming a gradual spherical distribution, so that the reflected intensity of the entire spherical target with different slopes is consistent.

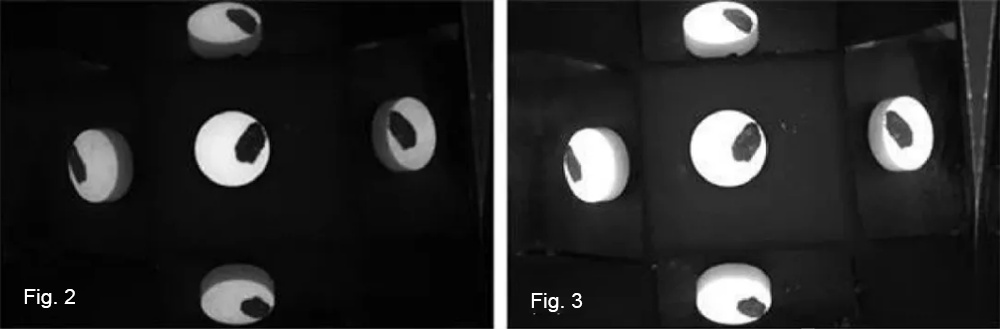

Because of the need to detect all surfaces of the tablet, the detection uses a prism module to cooperate with the light, through the split exposure to detect the defects of the front and the side, so as to obtain a 360 ° all-around image information of the apusule.

Image processing through software

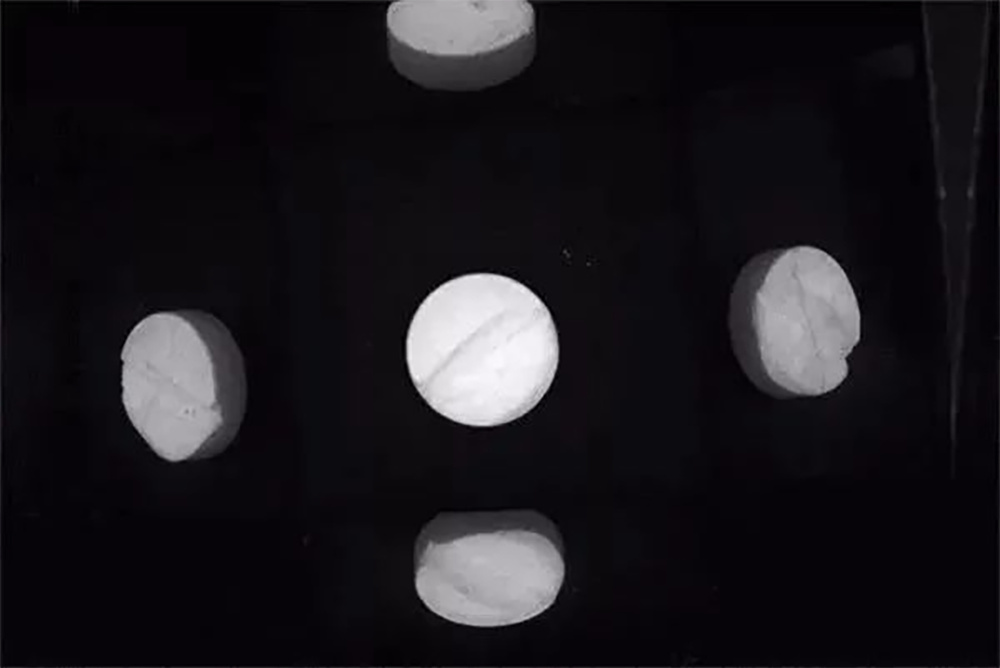

Detection of defects on the front side of the tablet

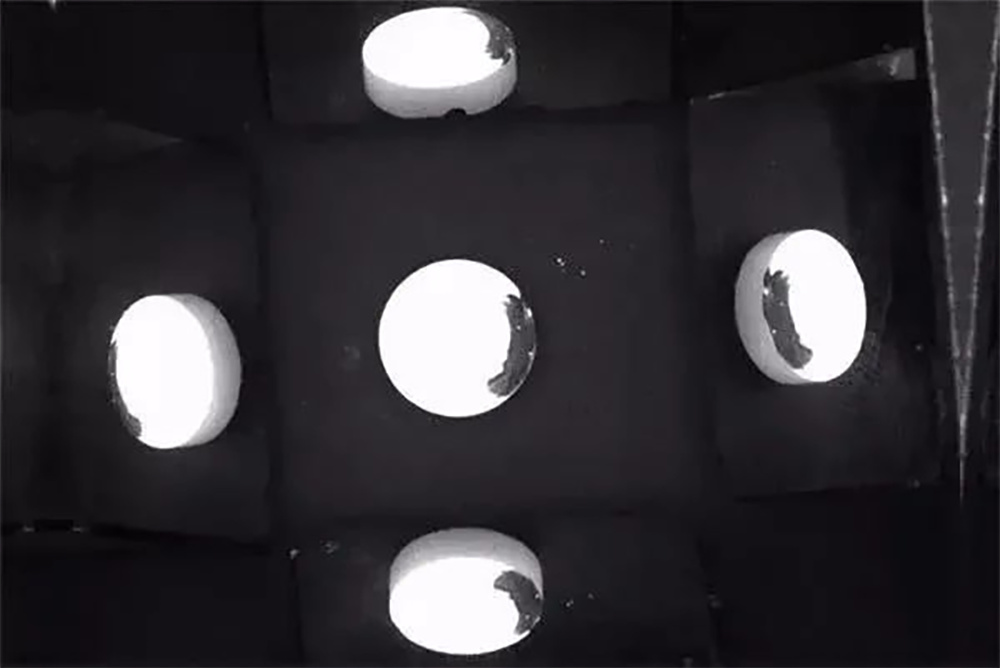

As shown in Fig 4, the image is acquired using low exposure, which retains more frontal details.

Fig 4:

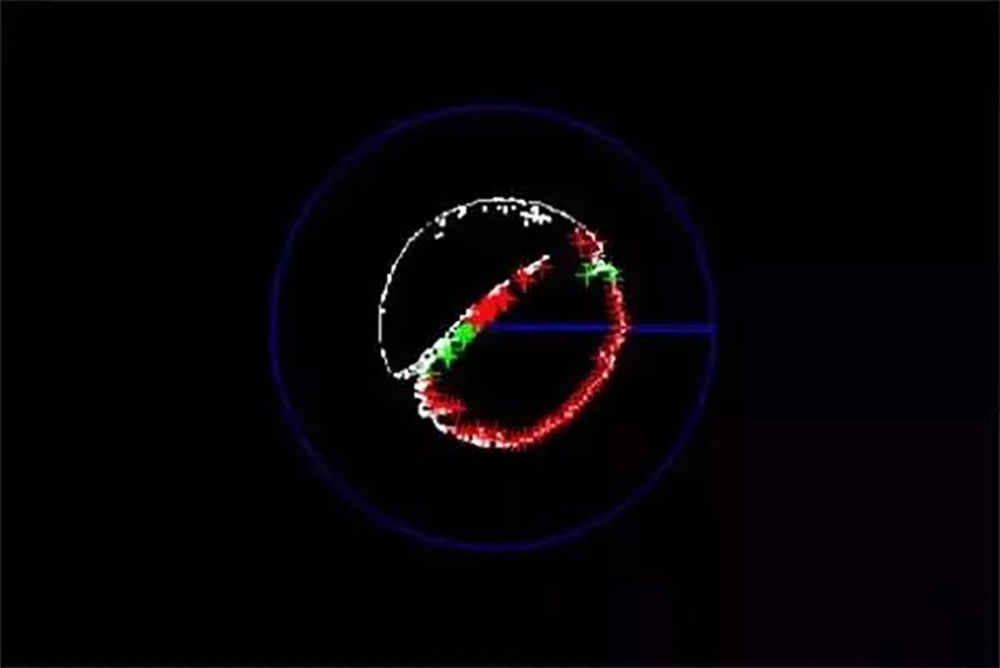

First, the image is modified using vision software. Absolute difference operation is performed on the image to enhance contrast between the edge of the pill and the defect, and then hit or miss operation is used to further expand and highlight the defect and edge contrast, and then obvious features are extracted by binarization. Finally, the chipping edge detection is used to calculate the degree of irradiation of the edge defect, which can identify whether there is a defect on the front side of the pill, and the final effect is shown in Fig. 5.

Detection of stain on the surface of the tablet

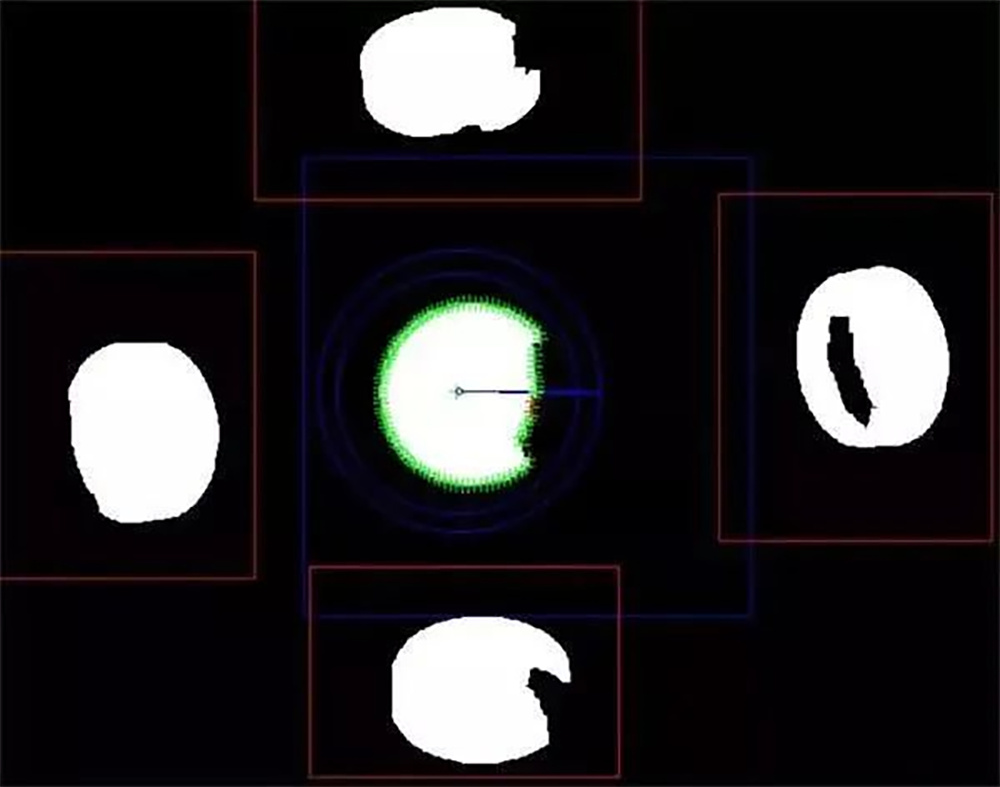

As shown in Fig. 6, the image is acquired with high exposure, the details are filtered, the contours are more obvious, and the sides become clearer for detecting front and side dirt and defects.

Fig6:

Using image preprocessing in vision software, the binarization operation highlights stains, compares them with pre-built templates, detects their integrity, and limits detection accuracy by limiting template matching.

Machine vision inspection is highly efficient, highly accurate, real-time, and can adapt to harsh inspection environments to achieve the goal of zero-defect production.

Benefit

Machine vision defect detection overcome the impact of traditional manual detection subjectivity, to meet the detection requirements of mass tablet production, while improving product quality, reducing production costs, reducing labor intensity of manual labor, with greater economic and social benefits.