The automation rate in the automotive industry is very high. The automation rate of ordinary car companies has reached more than 80%. The automation rate of new energy vehicles such as Tesla and Xiaomi SU7 is as high as more than 95%. Machine vision technology plays a vital role in the automated production of automobiles. It can fully realize the intelligent detection of various parts and components of automobiles, including automatic inspection of appearance, size, defects, etc., timely discover quality problems in the production process, and continuously optimize the production process through data feedback to ensure that each product meets strict quality standards.

The following briefly introduces 28 types of automotive parts inspection cases to take a peek at how defect detection is achieved in the process of automotive manufacturing automation.

1. Various inspections of operation panels

Inspection of button assembly errors and LCD display defects on operation panels. Conventional visual systems inspect the area and general graphic shapes of various marks, but there are cases where multiple cameras are required due to shape misdetection and insufficient recognition accuracy for large panel detection.

As long as the contour shape search function is used, it is possible to identify the contour information of the mark and achieve higher precision inspection. In addition, by using a high-pixel camera with a maximum pixel size of 21 million, even for large panels, a single camera can be used to uniformly inspect multiple locations with high precision.

2. Detection of poor bundling and welding of motor wires

Detection of poor bundling and welding of motor wires. It is difficult to distinguish the colors of wires, terminals, and solder using the visual system of a black and white camera.

We can accurately realize the wire extraction processing that was unstable in the past. Stable detection can be achieved even if the surrounding lighting brightness and workpiece glossiness change.

3. Detecting assembly errors in injectors

Detect assembly errors of various components in injectors by measuring external diameters and distinguishing colors. Conventional vision systems can cause errors due to false edge detection. Black and white cameras also have difficulty distinguishing component colors.

We can rely on unique edge detection algorithms to achieve stable detection and prevent misjudgments. The trend edge function that automatically determines the maximum and minimum diameters can also reduce setting times. Because it also supports color cameras, it can also distinguish components by color.

4. Identify the types of seat belt hardware

Detect subtle shape differences of seat belt hardware and identify the types. In traditional visual identification, if the production volume increases, a large number of inspection hours will be added, and the risk of missed inspection will also increase accordingly.

After introducing the machine vision system, full automatic inspection is achieved and missed inspection is eliminated. Even if the appearance difference is very small, it is possible to measure multiple points uniformly and achieve reliable identification.

5. Identify different types of gears

Identify differences in gear diameter and number of teeth and implement type identification. In the past, only visual inspection was performed during assembly, and sometimes different types of assembly were discovered after assembly was completed, resulting in a decrease in yield.

After introducing a visual system, it is possible to effectively prevent assembly defects by carrying out inspections before the assembly process. As long as the contour shape search function “ShapeTrax” is used, stable detection can be achieved even if the brightness and color of the workpiece surface and background fluctuate.

6. Identify different types of connecting rods

Different types can be identified by measuring the full length and diameter of the connecting rod. In the past, vision inspection was performed before the production line was put into use, and sometimes different types of parts were not found until the assembly process.

Using the visual system, the full length and diameter of the connecting rod can be measured while the product is being conveyed through the assembly line, preventing mixing of different types. Even subtle differences in hole diameter that were difficult to distinguish in the past can be measured, achieving correct type identification.

7. Detecting the amount of grease applied

Detect the amount of grease applied. In the past, color sensors were used to distinguish only the presence or absence of grease, and even objects with a small amount of grease applied would be judged OK.

Even if the color tone of the grease or workpiece surface fluctuates, stable detection can be achieved. In addition to judging the presence or absence, the 3D detection function can also measure the area and volume of grease applied to determine whether the amount is appropriate.

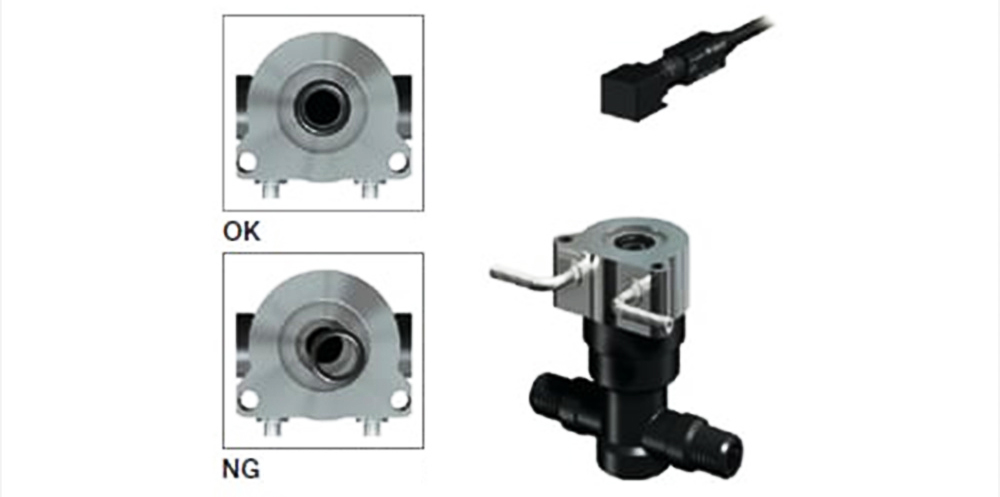

8. Detecting the presence and offset of O-rings during EGR valve assembly

In the EGR (Exhaust Gas Recirculation) valve assembly process, the offset position is detected before pressing in the O-ring. In the past, the position before pressing in could only be checked with the naked eye, which was difficult to detect and lacked accuracy.

However, by introducing a visual system into the inspection process, accurate automatic inspection can be achieved. By using the contour shape search function, stable inspection can be achieved even if the background color fluctuates.

With the help of an ultra-small camera (12 mm angle) and a side mirror, installation in a small space is possible.

9. Determine the installation position of the workpiece in the hot forging metal mold

In the hot forging process, determine the installation position of the workpiece in the metal mold. In the past, for the stamping cycle of only 3 to 5 seconds, operators were required to confirm, and occasionally defective products were missed.

Using machine vision equipment, the contrast of the original image can be enhanced according to color depth processing, and will not be affected by infrared rays emitted by red-hot metal, achieving stable and labor-saving automatic detection.

10. Detecting the mixing of different wheel varieties

Detect wheel shape differences to prevent mixing of different varieties. Traditional visual systems have difficulty distinguishing subtle differences.

Machine vision equipment can distinguish subtle shape differences based on contour shape search functions and edge information, and accurately detect differences between varieties.

11. Identify different types of tires

Prevent different types from mixing by detecting differences in tire color markings. It is difficult to correctly identify the difference in markings with traditional black and white images.

Using a color camera, you can detect shade from color extraction and accurately identify different types. There are many types of color cameras available, and you can choose a camera with the right number of pixels, specifications, and transmission time according to the detection content.

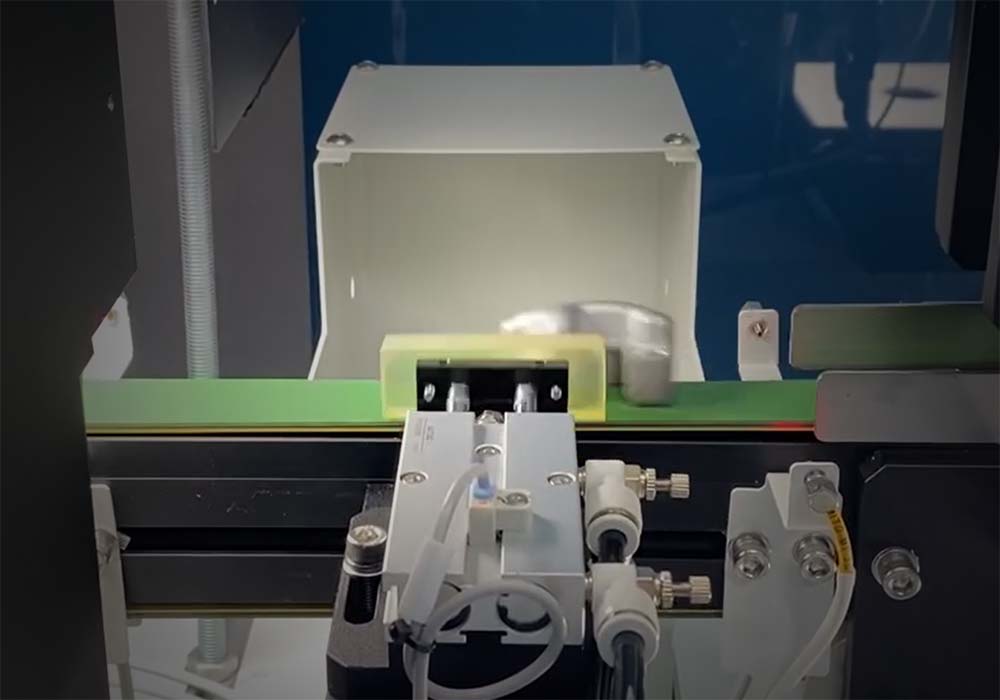

12. Detection of liquid sealant (FIPG) application

Detection of defective liquid sealant (FIPG) applied to various components such as engines, ATs, and oil pans. In the past, this process relied on visual inspection. Although it was possible to determine the situation of missing coating, the judgment of details such as thickness would be biased due to individual differences among inspectors.

As long as the trend edge width mode is used, continuous multi point measurement of the application range can be performed to accurately detect thickness. At the same time, it has a historical image storage function, which can detect the faulty part later, which is also one of its advantages.

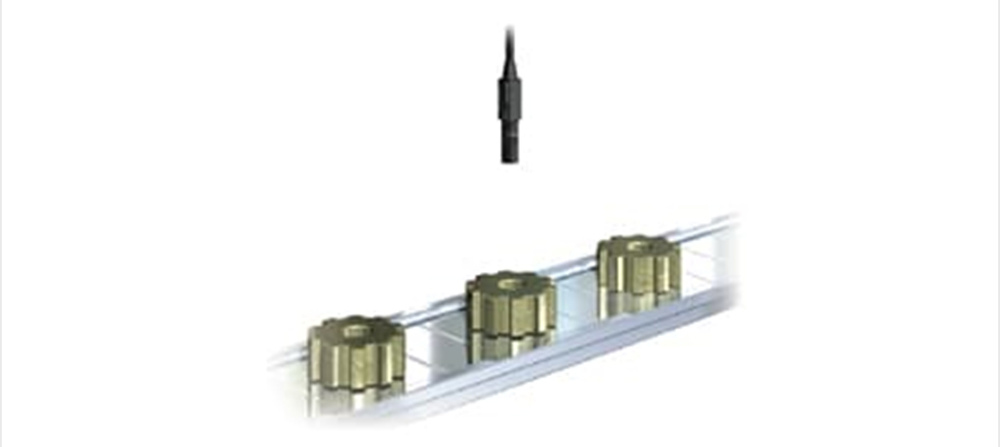

13. Detecting holes in camshafts

Detect holes in the camshaft surface as it rotates. In the past, this process relied on visual inspection for full inspection, which not only led to missed inspections, but also increased labor costs.

With a line scan camera, cylindrical products can be accurately inspected. After introducing a visual system, not only can accurate full inspection be achieved, but inspection costs can also be reduced.

14. Detect the appearance of bearings

After introducing the visual system, it is possible to accurately detect assembly errors and the appearance of the size, outer wheel, and inner wheel. It can also easily support multiple production lines.

15. Detection of chip adhesion on piston

Detection of chips on the piston groove. In the past, this process relied on visual inspection by inspectors, which resulted in deviations in human judgment and inconsistent inspection standards.

This is different, and quantitative inspection of LED light emission can be easily achieved.

In addition, traceability can be supported by transferring and saving both the inspection value and the actual inspection image to a computer.

16. Bearing quality inspection

Detecting ball drops from bearings. In the past, this process relied on vision inspection counts, and there were cases of missed detection.

By using the “Spot Mode”, which is one of the equipped vision system modes, the balls can be counted instantly and full inspection can be achieved.

17. Detect burrs and defects on O-rings

Detect burrs and defects on O-rings. Conventional vision systems have difficulty measuring circular distortion, etc., and the detection results fluctuate due to this.

By using the trend edge defect mode for detection, it is possible to avoid the influence of the slight circular distortion of the O-ring and only perform full high speed detection of sudden deformations such as burrs and defects.

18. Various inspections of measuring instruments

Use visual systems to inspect the position and angle of measuring pointers. In traditional methods, visual systems must perform many complex calculations to measure various positions and angles. In addition, false detection of edge positions and insufficient accuracy of 240,000 pixel cameras are also problems.

For edge detection alone, 8 inspection modes are equipped, and the necessary position and angle measurements can be achieved without complex calculations. You can also choose from cameras ranging from 310,000 pixels to 21 million pixels to achieve high-precision measurements that meet the needs of the application.

19. Detecting the gap size of the piston ring

Measure the joint of the piston ring. In the past, this process was detected using a contact feeler gauge, but with stricter tolerance management every year, the insertion of the contact feeler gauge will cause data fluctuations and cannot be correctly detected.

The visual system can achieve quantitative management without relying on inspection personnel and easily achieve complex dimensional measurement. It can also detect calculations such as R-section dimension measurement, finding virtual intersections between straight lines, and hundreds of varieties.

20. Measuring the skew of the vehicle body

In the past, measurements were made using strain gauges, which were time-consuming and laborious in preparation and measurement.

The visual system can measure body skew by detecting the position of the light spot of the laser pointer. Since the detection object is the relative position change relative to the reference position, the body skew can be accurately measured.

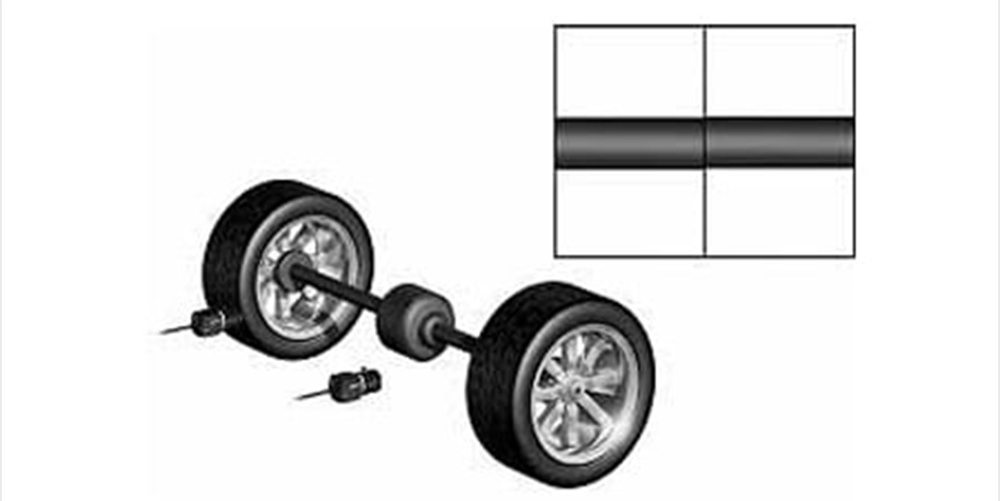

21. Measuring the parallelism of the drive shaft

In the past, dedicated inspection equipment was required, which was costly to introduce.

With machine vision equipment, two cameras can be used to measure the position of the shaft and parallelism respectively. It is also highly versatile, and the use of a telephoto lens can also achieve high-precision measurement over long distances.

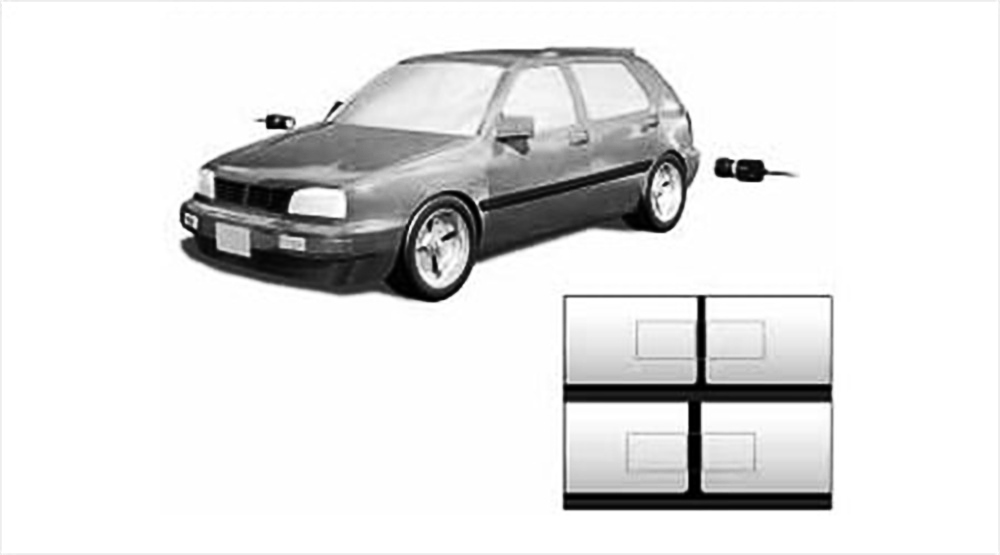

22. Detect the assembly status of the car door

Detect the accuracy of the car door assembly. Traditional human visual and gauge measurement has a large detection error, and the use of gauges to measure also has the disadvantage of contact.

After introducing the machine vision system, labor costs can be reduced and the risk of contact can be avoided. Equipped with a “geometric measuring tool” specifically for geometric measurement, after selecting the geometric tool, you only need to specify the target with the mouse to achieve geometric measurement.

By measuring the gap size of the car door, you can easily detect whether the assembly accuracy is qualified.

23. Welding position detection and positioning

Before bending, the weld position is detected. In the past, this process was implemented using fiber optic sensors and color sensors. There were deviations in the surface conditions of different batches, and light spot detection would lead to false detection.

After introducing the visual system, it is possible to prevent the outflow of defective products due to misoperation. The defect/stain detection mode used can accurately detect the weld position through color changes. This eliminates the need to adjust the sensitivity for deviations in each batch.

24. Positioning hole sensing when assembling the car body

Using a machine vision system to control the robot arm’s position, the assembly of heavy parts such as the front windshield and door is performed. In the past, it was a major technical challenge to implement position detection for various workpieces, so it was difficult to achieve automation.

Using contour search and multi-point edge detection, virtual circle detection and flexible search can be performed, supporting various workpieces and surface conditions, and achieving automation.

It also supports various robot manufacturers and can be connected directly without complex programming. It is also equipped with an automatic correction function, which greatly shortens the startup time.

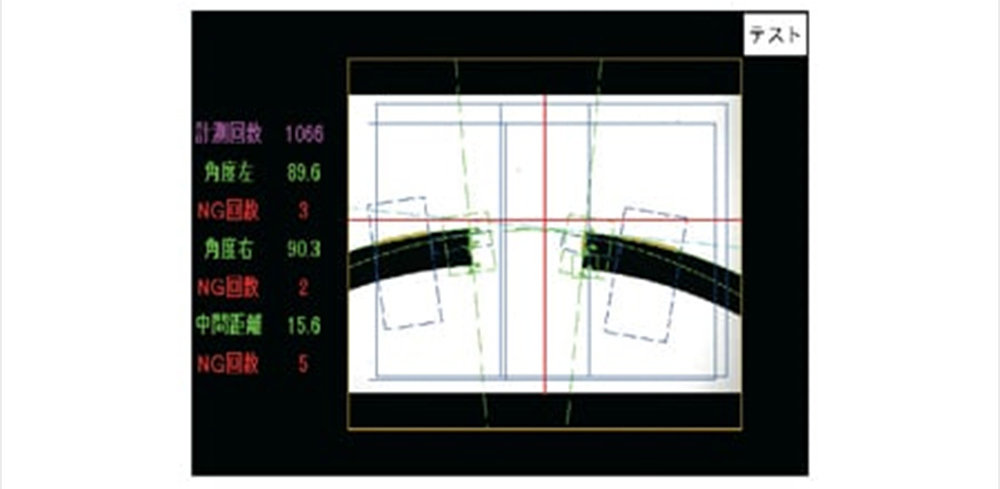

25. Detecting gear notch angle

Measure the notch angle to control the correct angle of the assembly process. The traditional measurement method is to rotate the workpiece and use a fiber optic sensor to detect the presence of the notch to obtain the angle. This method has problems with time-consuming positioning and misdetection due to the offset of the center position of the component.

The trend edge function can detect the virtual center of the circle and detect the center of the workpiece based on the outer periphery. It can also use the notch for linear detection at the same time to achieve high-speed and high-precision rotation angle detection.

26. Control position of the robot arm

The position of the assembly and processing robot arm is controlled by the visual system. In the past, this process had to be manually debugged, which increased startup time.

The visual system detects the hole position of the car body and then feeds back to the robot, which can achieve automatic positioning. Even if the position of the workpiece is slightly offset, it can be corrected, and manual confirmation is no longer required. High precision detection can be achieved with sub pixel processing technology.

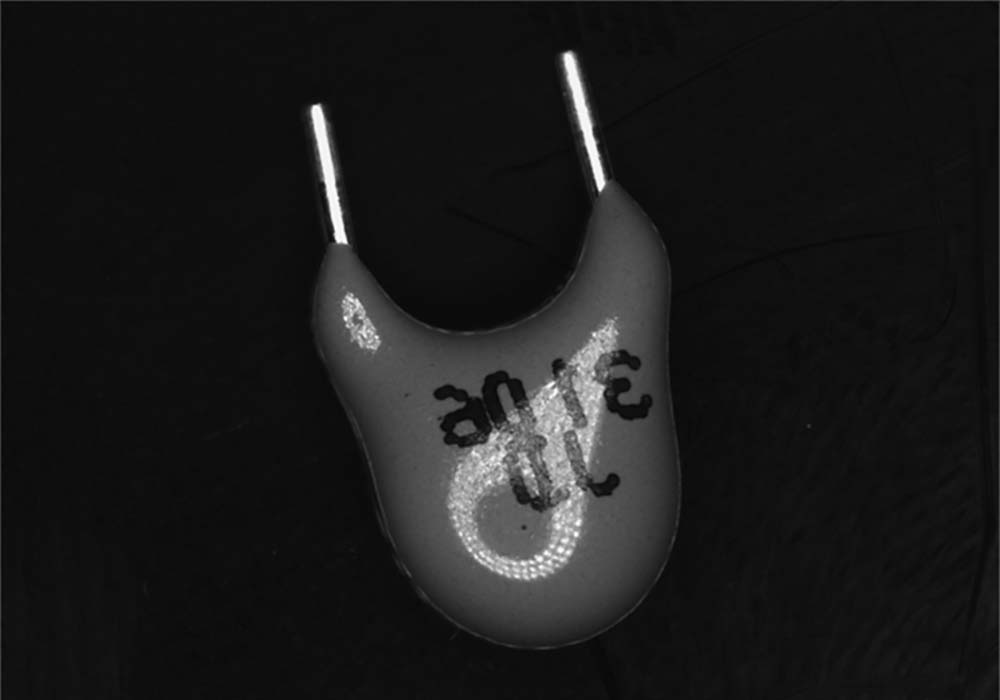

27. Seat belt buckle OCR

Recognize the characters engraved on the buckle part and implement product identification. Through character recognition, domestic/foreign products and products for left/right steering wheels can be identified. In the past, this process relied on visual inspection, and occasional misdetection would lead to the mixing of different products. Since car seat belts are safety components, low-level errors such as mixing different products are not allowed.

After introducing the visual system, accurate full inspection can be achieved, effectively eliminating the mixing of different products. The advantage of visual system inspection is that it can accurately show the shadows of the engraved surface and the workpiece surface. It provides a variety of lens and lighting options, and the unique OCR function can cope with changes in engraving thickness, character tilt, character size changes, etc., to achieve stable inspection.

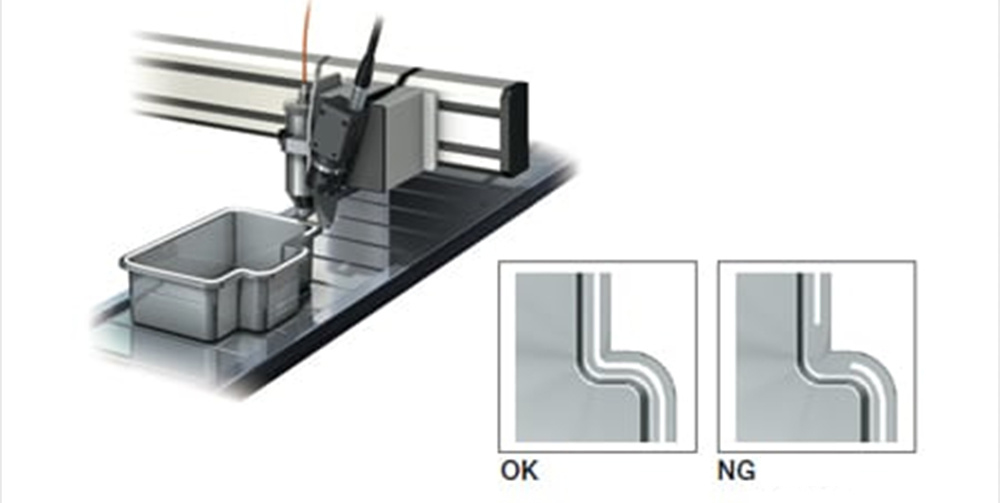

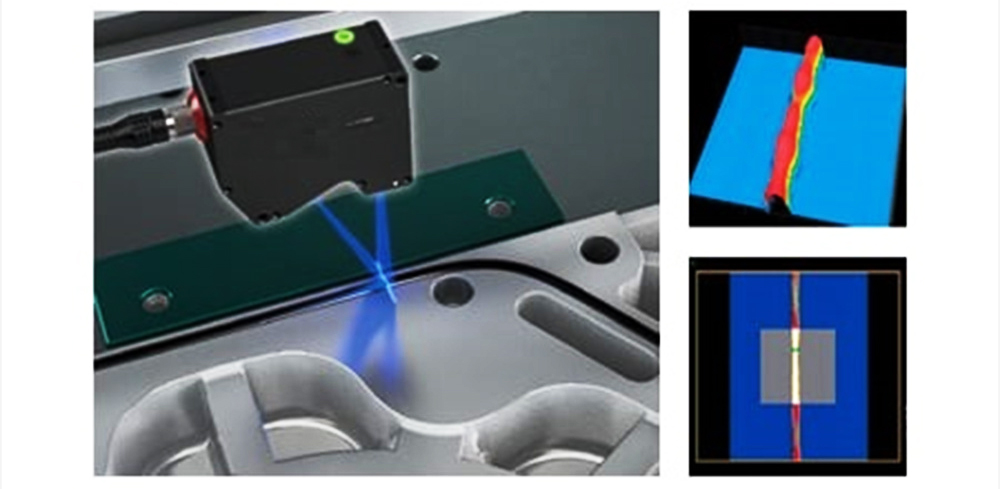

28. Measuring the application range and volume of the sealing coating

Measure the shape of the sealing material and detect the amount of application. Conventional 2D cameras cannot determine height and cannot determine whether the application amount is correct.

It can be connected to an ultra-high-speed profile measuring instrument to measure height, width, position, cross-sectional area, volume, etc. through a 3D vision system to automatically detect the amount of sealing material applied. It can also correct the position deviation of the target object in real time.