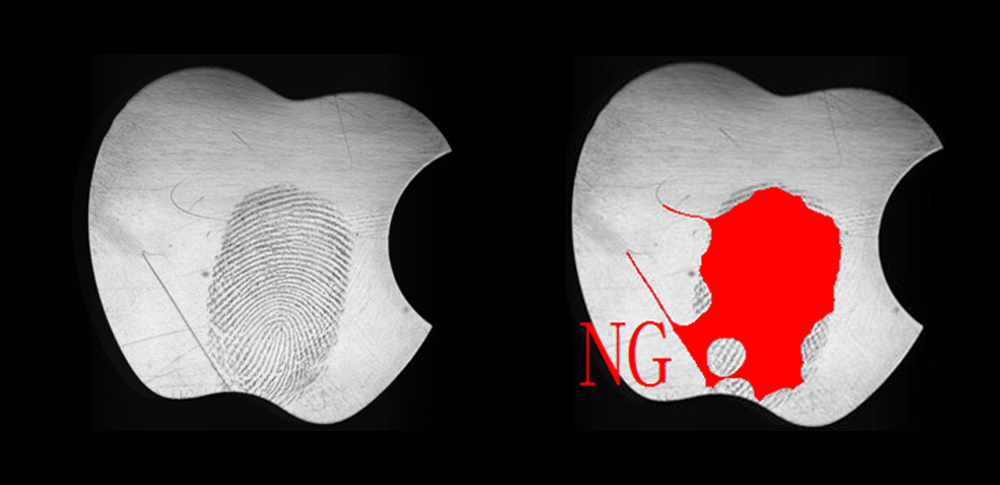

In industry, high-gloss materials are used to process some workpieces with high flatness and high surface requirements, such as mobile phone logos, light guide plates in military equipment and other products. The following figure shows Intsoft Tech detecting defects for the Apple logo.

This type of workpiece itself is mirror-reflective, the workpiece itself has high flatness, and is easy to stick to oil stains, fingerprints, etc.

Difficulties

Reflection problem: Since the surface finish of the material is very high, a high-gloss mirror has been formed. Even when the light source is very weak, the reflection on the surface will have a very strong contrast. This contrast will cover impurities, scratches, grinding marks and other defects on the surface itself, making it impossible to detect surface defects of parts by visual photography.

Reflection problem: Since the surface of the material has formed a mirror, general optical lenses and light source beads will form reflections on the surface of the material. This reflection will be imaged on the final detection screen, which will seriously affect the imaging effect of the material surface and make detection impossible.

Solution

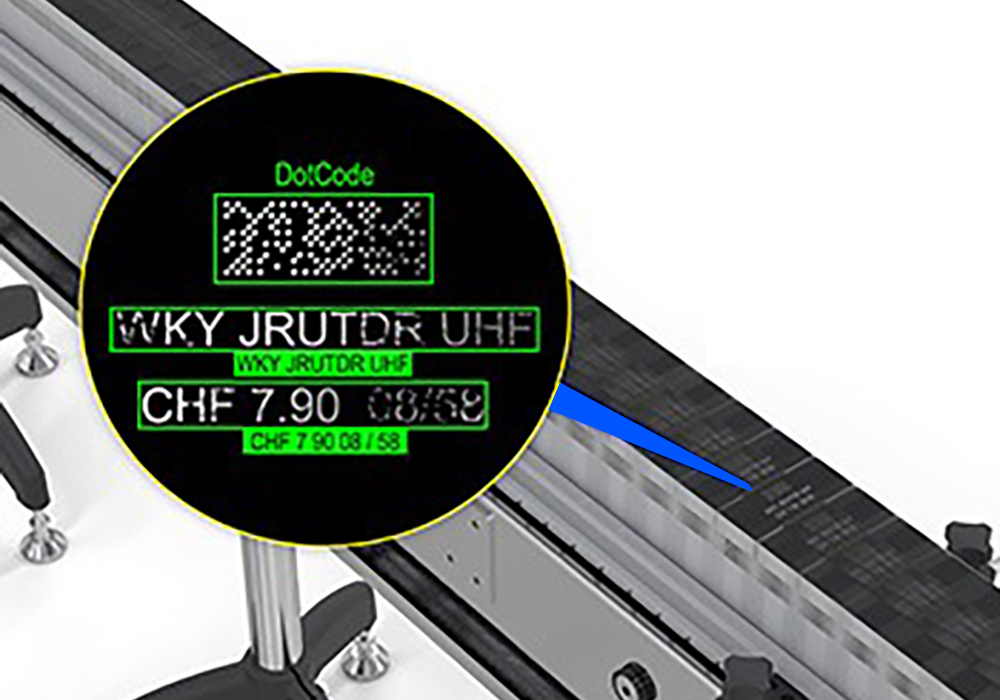

Reflection problem: BT series telecentric coaxial illumination imaging system uses parallel light

Reflection illumination, the optical principle of parallel light imaging, can perfectly solve the mirror reflection problem. Even if there are tiny scratches, abrasions, fingerprints, oil stains and other defective features on the surface, they will be presented with a high grayscale contrast, greatly reducing the difficulty of the later image algorithm.

Reflection problem: BT series coaxial illumination imaging system (BT-2348+BT-CP64/X parallel coaxial light), with high optical path parallelism, uniform light spot and full coverage of the test sample itself, will not produce the reflection of the system hardware on the mirror itself.

Left side image: Telecentric lens + BT series parallel coaxial light / Right side image: inspection analytics image