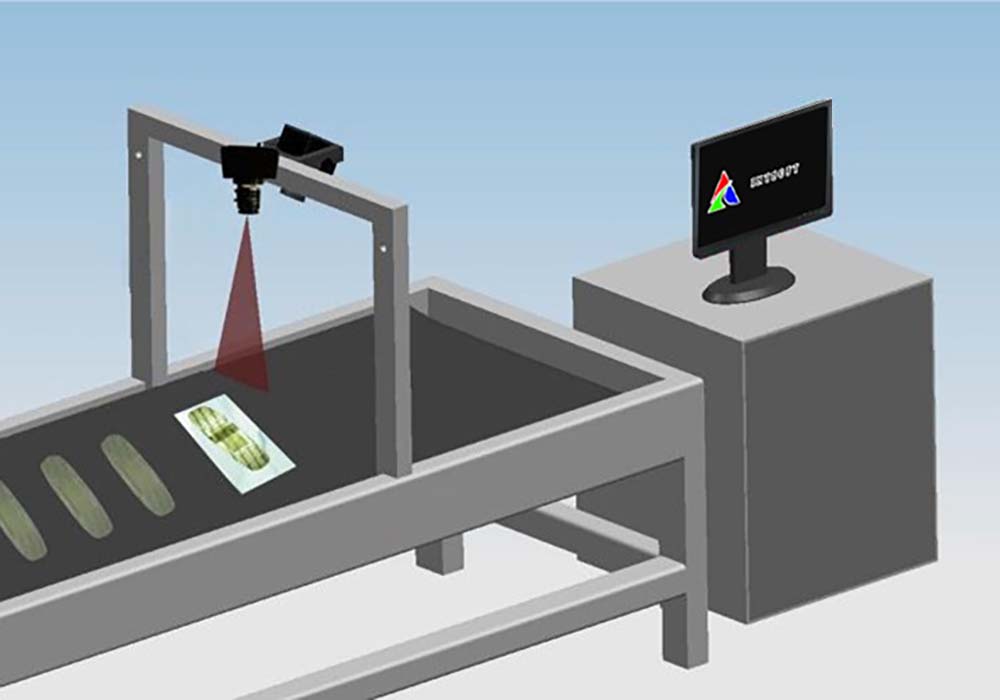

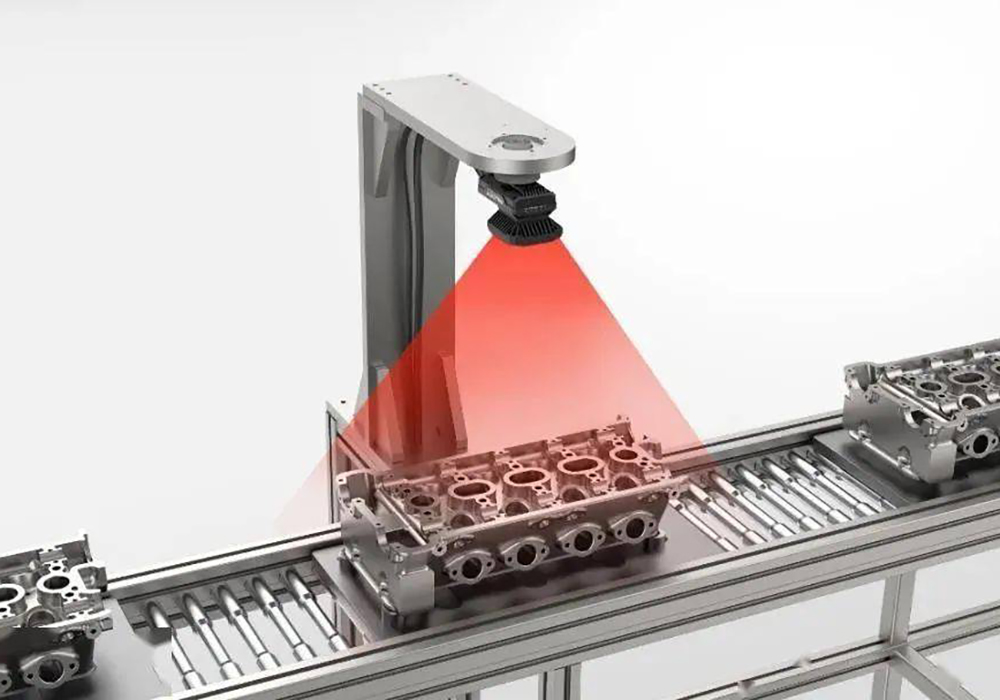

How does vision inspection work?

Vision inspection works like a smart camera that takes pictures of things, looks closely at them to find any problems or special features, and then decides whether they are good or bad based on what it sees. As a key component of modern automation and quality control processes, machine vision system operates by…