After harvest, fruit and vegetable quality is often assessed using color and other visible characteristics to determine factors such as ripeness, uniformity of shape and size, and the presence of skin and flesh defects, while other assessments focus on texture-related characteristics such as firmness, toughness, and tenderness. Quality assessment helps determine the appropriate processing and applications for each fruit or vegetable, such as peeling, slicing, canning, syrup preparation, or direct fresh fruit consumption.

Challenges of traditional fruit sorting

Traditionally, fruit sorting has been a labor-intensive and subjective task, relying on the keen eyes and experienced judgment of human workers. These manual sorting methods, while effective to a certain extent, are prone to inconsistencies, errors, and throughput limitations. As production volumes have grown, the need for a more efficient and scalable solution has become increasingly apparent.

Embracing machine vision for automated fruit sorting

Enter machine vision, a technology that is revolutionizing the fruit sorting industry. By integrating high-resolution cameras, specialized lighting, and advanced computer vision algorithms, automated fruit sorting systems can now perform this task with unprecedented speed, accuracy, and consistency.

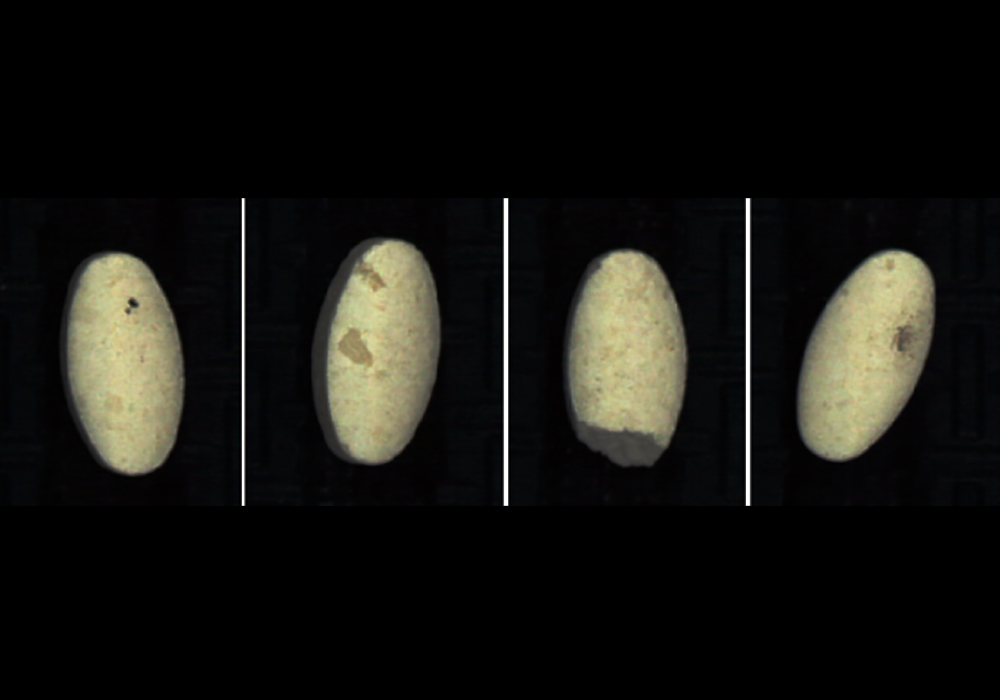

1. Comprehensive Fruit Evaluation: Machine vision-based sorting systems can capture detailed, multi-angle images of each piece of fruit as it passes through the system. These images are then analyzed by powerful algorithms that can assess a wide range of characteristics, including size, color, shape, texture, and even the presence of blemishes or defects.

2. Precise Classification and Grading: Based on the analysis of captured images, the machine vision system can automatically classify each fruit item into predetermined categories, such as size grades, quality grades, or intended end-use (e.g., fresh market, processing, or juicing). This granular classification allows for more efficient downstream handling and distribution.

3. High-Speed Sorting and Packaging: The rapid image capture and analysis capabilities of machine vision systems enable them to sort and divert fruit at incredibly high throughput rates, often exceeding the capabilities of manual sorting operations by orders of magnitude. This increased efficiency translates directly into higher productivity and cost savings for fruit growers and processors.

4. Consistent Quality Control: By removing the human element from the sorting process, machine vision-based systems eliminate the variability and subjectivity inherent in manual sorting. This ensures a consistently high level of quality control, reducing the risk of sending subpar products to market and minimizing the potential for costly product returns or recalls.

5. Adaptability and Scalability: Machine vision sorting solutions are highly flexible and can be easily reconfigured to accommodate changes in fruit varieties, packaging requirements, or processing workflows. This adaptability allows fruit producers to scale their operations and respond to changing market demands without disrupting their core business.

Benefits of automated fruit sorting with machine vision

The adoption of machine vision-powered fruit sorting has brought many benefits to the industry, including:

1. Improved Product Quality: By accurately identifying and separating fruits based on their unique characteristics, machine vision systems help ensure that only the highest quality produce reaches the consumer.

2. Enhanced operational efficiency: Automated sorting not only increases throughput but also reduces labor costs, minimizes handling-related damage, and streamlines the overall fruit processing workflow.

3. Increased profitability: Increased productivity, quality control, and operational efficiency translate directly into improved profitability for fruit growers, packers, and processors.

4. Expanded market access: The ability to consistently deliver high-quality, precisely graded fruit opens up new market opportunities for fruit producers, enabling them to reach a wider range of customers and distribution channels.

5. Sustainability and Environmental Impact: By optimizing fruit sorting and processing, machine vision-based systems can help reduce food waste and minimize the environmental footprint of fruit production.

As the fruit industry continues to evolve, the integration of machine vision technology into automated sorting systems is poised to become an essential component of modern, efficient and sustainable production processing operations.