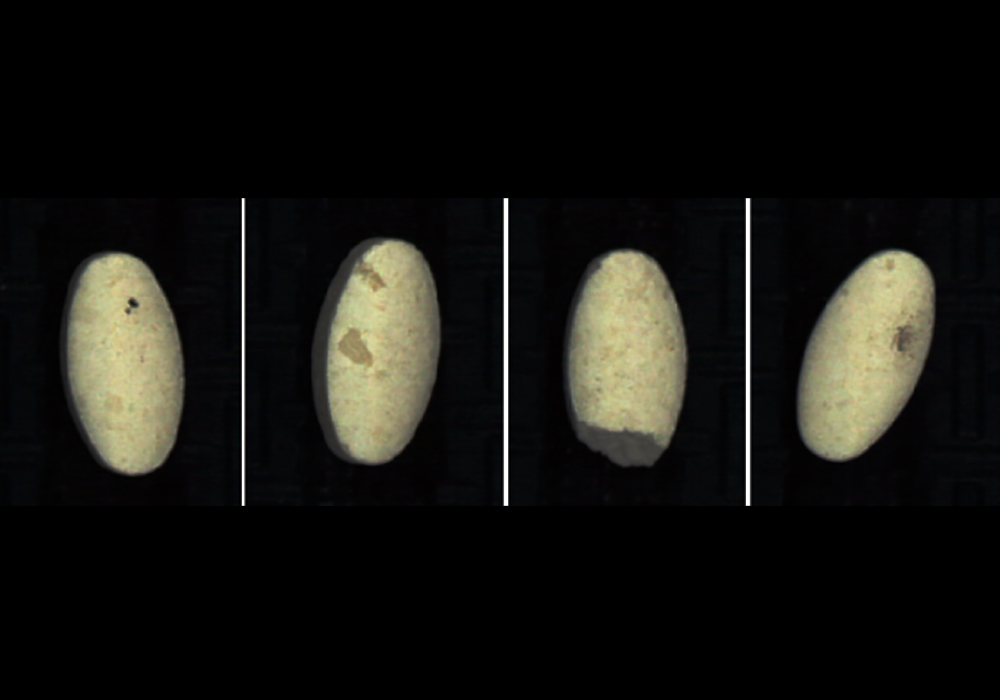

Pharmaceutical manufacturers often need to sort tablets with different characteristics such as different colors, different shapes, appearance defects, etc., or sort several tablets with specific characteristics into one piece in proportion to meet the needs of tablet inspection or dispensing. This inspection equipment is designed by Intsoft Tech for pharmaceutical factory customers to detect and sort tablets.

Inspection capacity

All-round inspection of tablets of various shapes, with inspection speed of up to 120,000 tablets/hour

Scope of application

Applicable to pharmaceutical companies for tablet appearance defects, shape inspection and color sorting.

Functional features

1. High resolution color linear array camera, good image quality and detection accuracy

2. Professional image processing and detection algorithms, effectively detect various defects on the surface of tablets, with high detection rate

3. According to rapid modeling and variety management for different products, qualified and unqualified products are automatically sorted.

4. Real-time recording and long-term storage of inspection data and defect images, which is convenient for tracking and analyzing the causes of defects

5. Based on long-term statistical data on various types of defects, a database can be provided for quality process improvement.

6. The light source adopts LED light source, which has a long life, high stability, good consistency and very low maintenance cost.

7. The equipment is easy to operate, maintain and clean, and meets GMP standards.