With the AI intelligent inspection system based on deep learning algorithms, it can directly complete all kinds of quality inspections in the automobile manufacturing industry and truly make the automobile intelligent manufacturing.

Machine vision solutions for the automotive industry

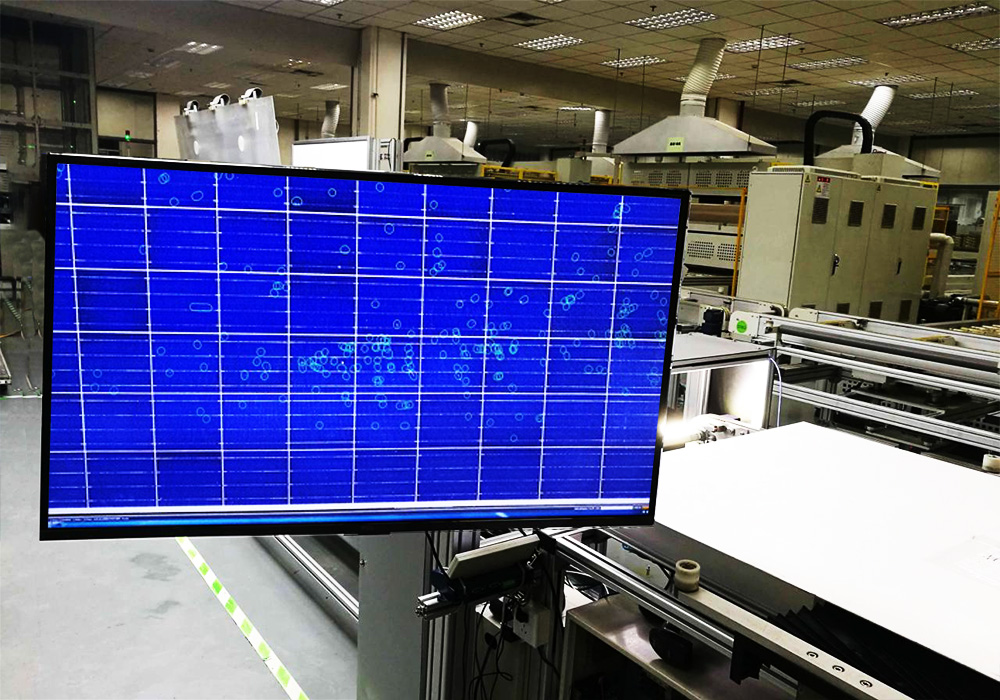

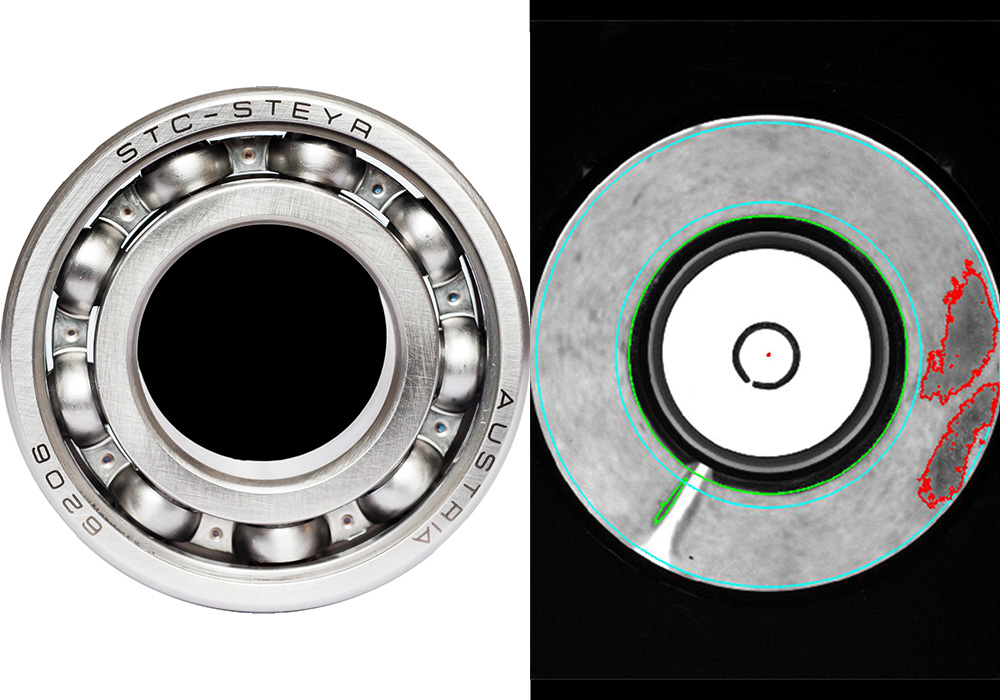

Intsoft Technology applies machine vision technology to automotive quality inspection, quality inspection and information traceability of various parts, such as automotive glass, tires, lithium diaphragms, instrument panels, center control displays, seats, components, etc., which helps automotive manufacturers improve product qualification rate and enhance production efficiency.

How Intsoft Technology AI VISION helps you improve automobile production?

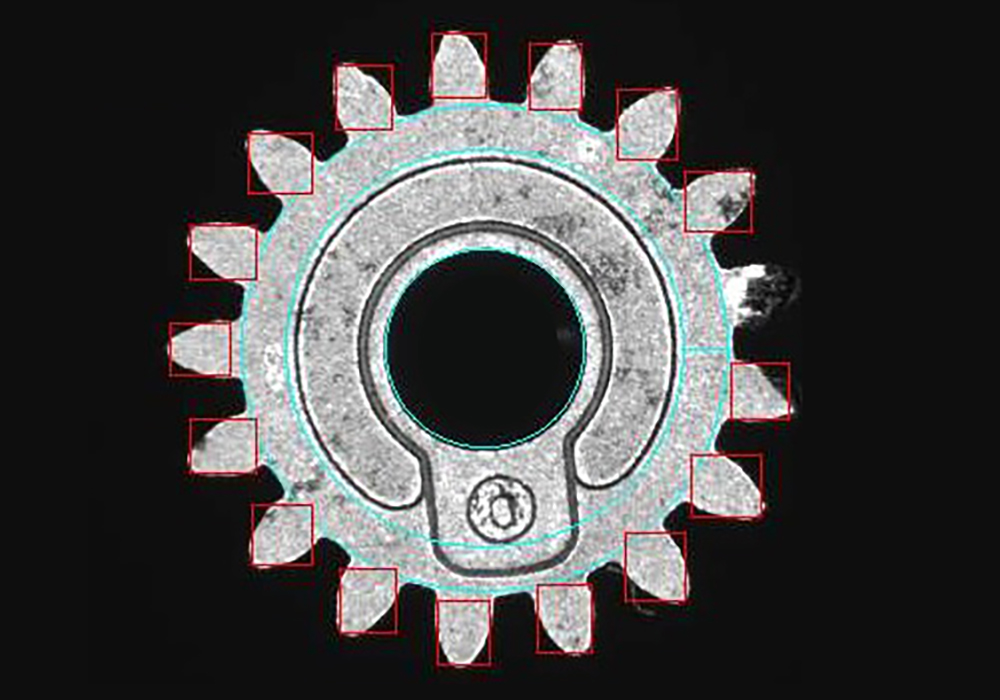

Quality Control: Machine vision systems can be used to automate and improve the quality control process in automotive manufacturing. They can inspect parts, assemblies and finished vehicles for defects with high speed and accuracy, reducing manual inspection and improving product quality.

Autonomous Driving: Machine vision is a critical component of autonomous and semi-autonomous driving systems. Computer vision algorithms can detect and recognize objects, lanes, traffic signs, and other road elements to enable self-driving capabilities.

Advanced Driver Assistance Systems (ADAS): Machine vision can power ADAS features such as lane departure warning, pedestrian detection, traffic sign recognition, and collision avoidance to improve driver and passenger safety.

Production Optimization: Computer vision can be used to monitor and analyze production processes in automotive plants. This can help identify bottlenecks, optimize workflows, and reduce waste and downtime.

Predictive Maintenance: Machine vision can be used to inspect vehicle components and systems for wear and tear, enabling predictive maintenance strategies that reduce unplanned downtime.

Inventory Management: Computer vision can automate the tracking and management of inventory, parts, and materials throughout the supply chain and manufacturing process.

Defect Detection: Machine vision systems can quickly and accurately identify defects in automotive parts and components during the manufacturing process, reducing the risk of faulty products reaching the customer.

Ergonomics and Safety: Computer vision can monitor worker movements and posture in factories to identify potential ergonomic issues and safety concerns, helping to improve workplace conditions.