Through Intsoft Technology photovoltaic panel appearance detection machine, we can automatically identify module-related defects, using visual recognition to replace traditional manual observation, not only saves labor, but also makes up for manual observation of visual fatigue caused by missed detection, for the photovoltaic manufacturing industry to play an important role in quality control.

Machine structure

The machine is divided into two sections: the test section and the display section.

Test section: strip structure, including test line scanning camera and test strip light source.

Display section: includes 4K monitor, host, keyboard, mouse and related input, output device.

Installation requirements

The machine uses the factory’s original assembly line, and the machine can be inserted into the assembly line for installation. Requirements for the assembly line of factory:

1. The assembly line should be supplied by factory to ensure that the flow rate of components is uniform and equipped with a homing system.

2. The gap of the assembly line should be 20cm-25cm to ensure that there is no obstruction in the vertical direction of the gap.

3. The direction of the assembly line should be the short side flow direction.

Machine work flow

Components enter station A –> Components flow to station B -> Machine completes the acquisition of the front appearance image of the components -> Within 15 seconds, the software will automatically identify the location of defects in the appearance of the components and label them for storage.

The machine in the detection process does not affect the original assembly line function. It is an independent testing system. It uses its own sensors to initiate component detection signal acquisition.

The software can also feedback the OK/NG signals of the test results to the PLC in the assembly line, and the assembly line will perform sorting.

How does the machine perform defect identification?

| Detection item | Defect type | Defect description |

| Battery piece | Crack, perforation | Length or dia. greater than 2mm |

| Broken edge, missing corner | Incomplete battery shape | |

| scratch | Length greater than 2mm | |

| Dirty | foreign matters on it | |

| Laminated module front | Battery piece misalignment and spacing Abnormal | Battery piece spacing Abnormal |

| Flux residue | The flux residue on the cell during automatic string soldering | |

| Foreign matter on the glass surface | Glue residue or other foreign matters | |

| Hollow, bubble | Hollow bubble group on the battery piece surface | |

| Glass scratches | Length greater than 2 mm | |

| Laminated module back | Optional |

Detection case

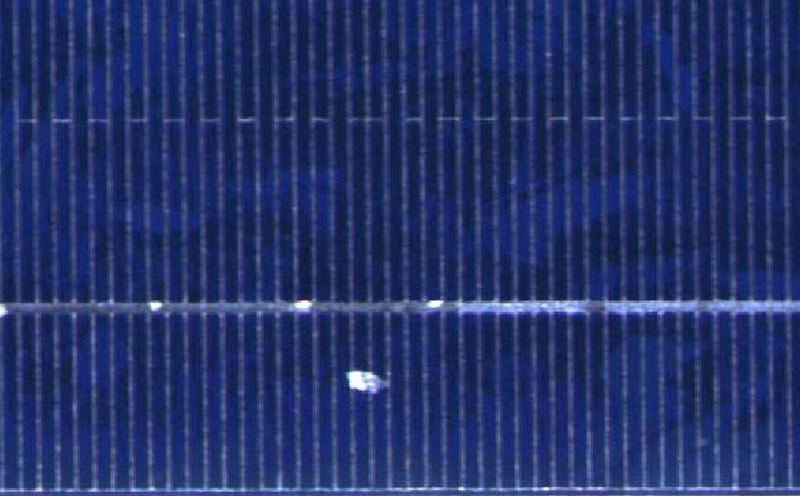

1. Defect type: foreign matter

Original image:

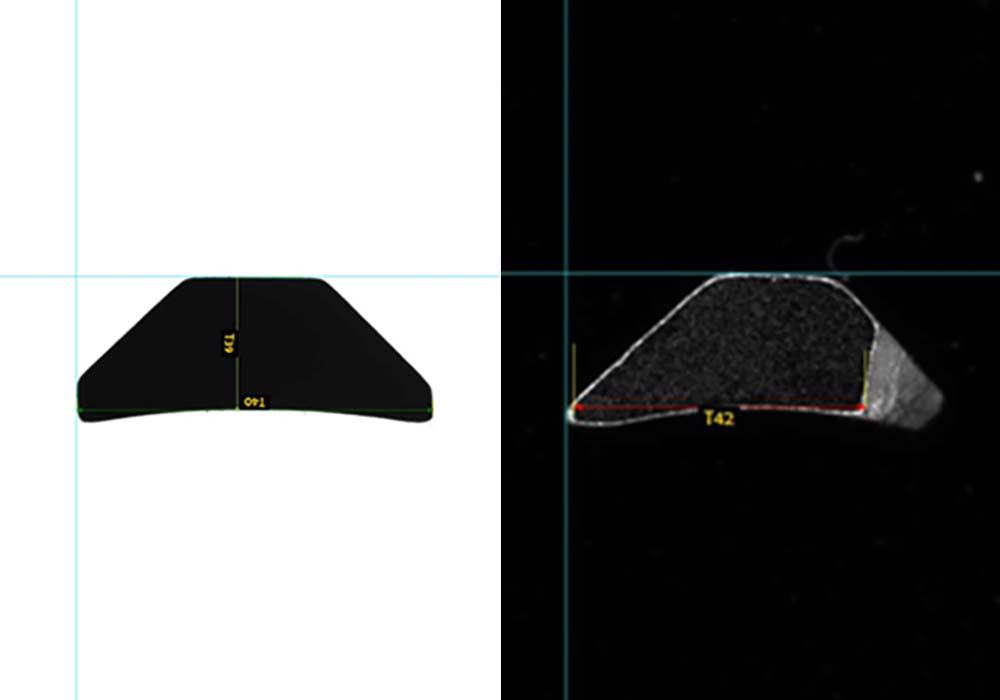

Detection result image:

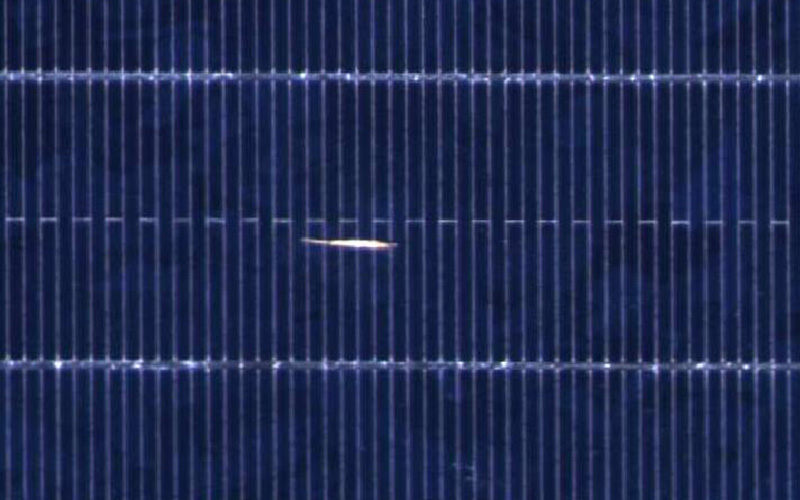

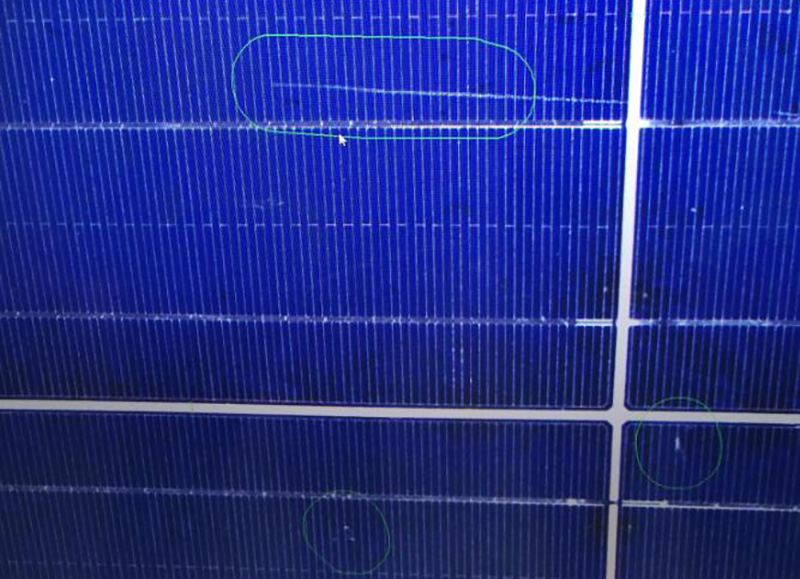

2. Defect type: Flux residue

Original image:

Detection result image:

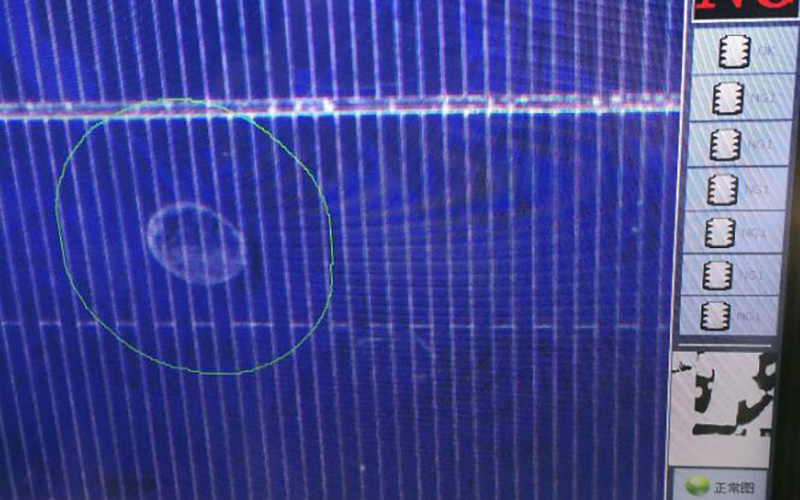

3. Defect type: Scratches and bubble

Original image:

Detection result image:

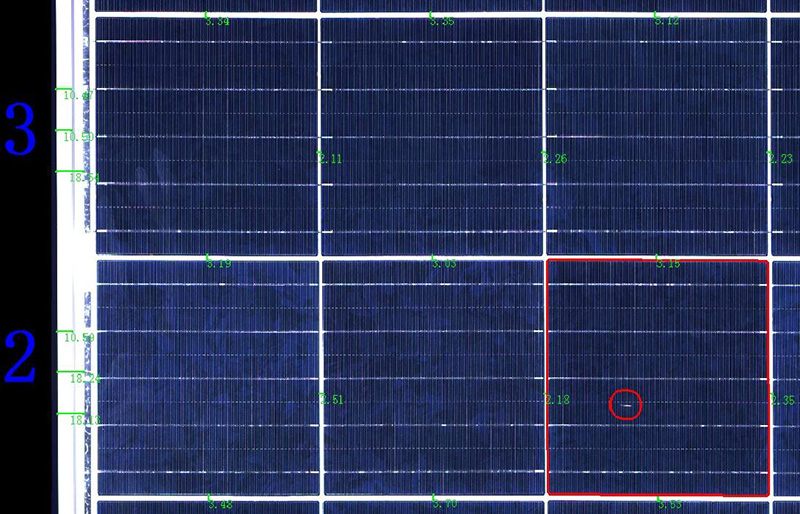

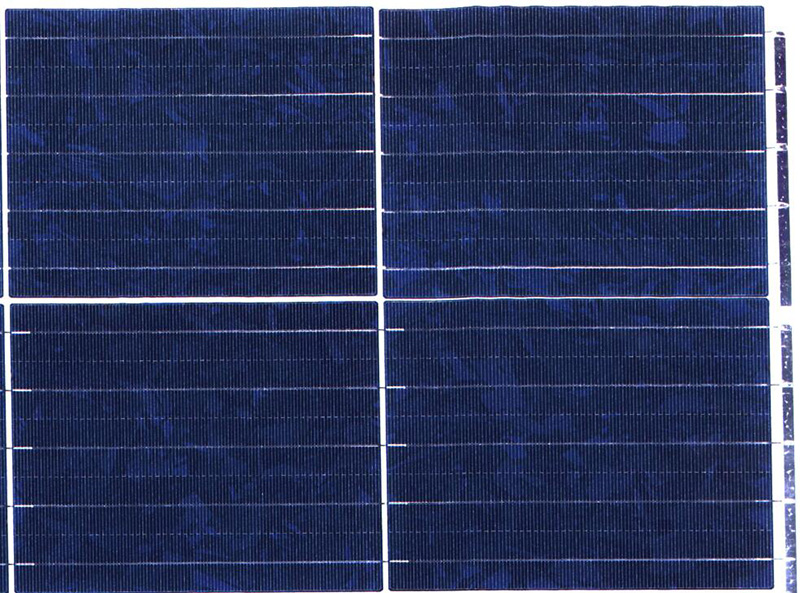

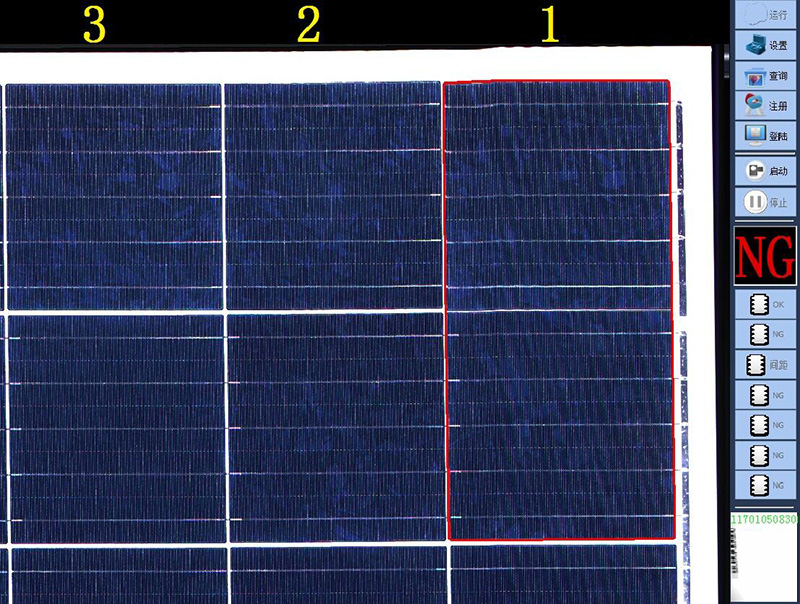

4. Defect type: battery piece spacing anomaly

Original image:

Detection result image:

Machine software function

1. Defect circle: Defects in the test image will be circled by color.

2. Defect position marking: Defect position can be labeled according to the horizontal and vertical rows and columns of the battery piece, such as A2, B3, E4.

3. Automatic Image Correction: The software can automatically correct the image of the component if the image is incorrect or distorted due to the fact that the assembly line can not guarantee full uniform speed and the return of the component to the correct place.

4. Automatic image storage: The image can be saved according to the current time and date, the image size can be compressed and stored as a percentage.

5. Automatic barcode saving: At the back panel of the machine, there is a graphic scanner. The back panel of a specific area of the barcode can be used for image recognition and storage.

6. Database query: The software has a built-in database query function. The user can look up the appearance of the component image according to the date of the picture or barcode to find the history of picture defects.

7. Other software functions: Other software customization requirements can be completed according to the customer.