Intsoft Technology has developed a comprehensive machine vision-based approach to precision hardware defect detection that is highly effective in a wide range of manufacturing environments. By leveraging state-of-the-art vision hardware and advanced software algorithms, Intsoft is able to deliver robust and reliable inspection solutions that can identify even the most subtle defects on critical parts and components.

Case 1: Round precision hardware parts defect detection

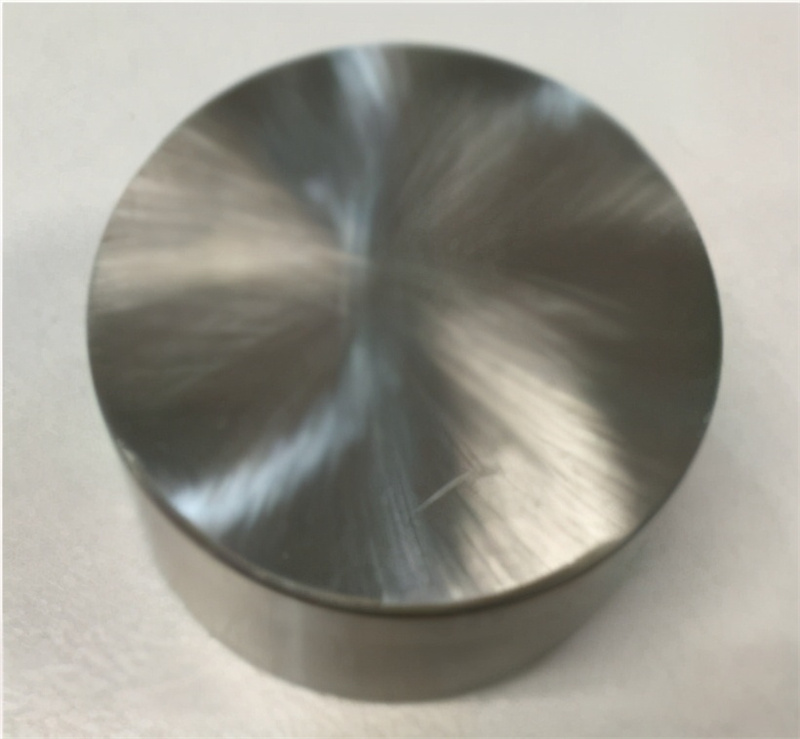

In the metal part of the image below, there are two defective surfaces. These malpractices are due to scratches that are very common during production:

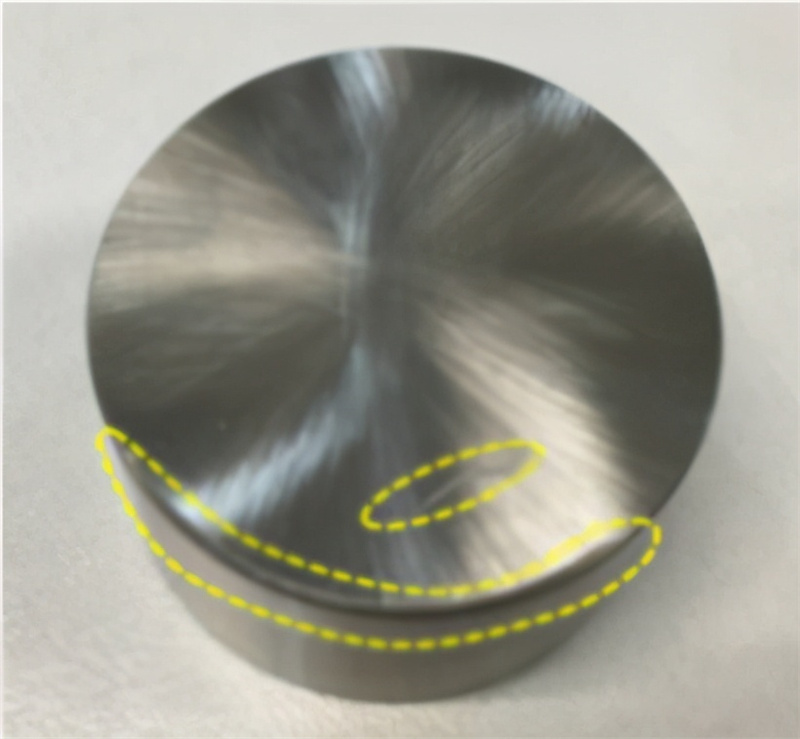

Reveal the location of these two defects, as shown below in the yellow highlights:

Defect1: Scratch

Defect 2: Edge missing

This type of defective appearance color, which is the same color as the background, can not be distinguished by ordinary cameras and requires the use of a 3D camera.

Analysis of the two types of defective

Defect 1: Scratch

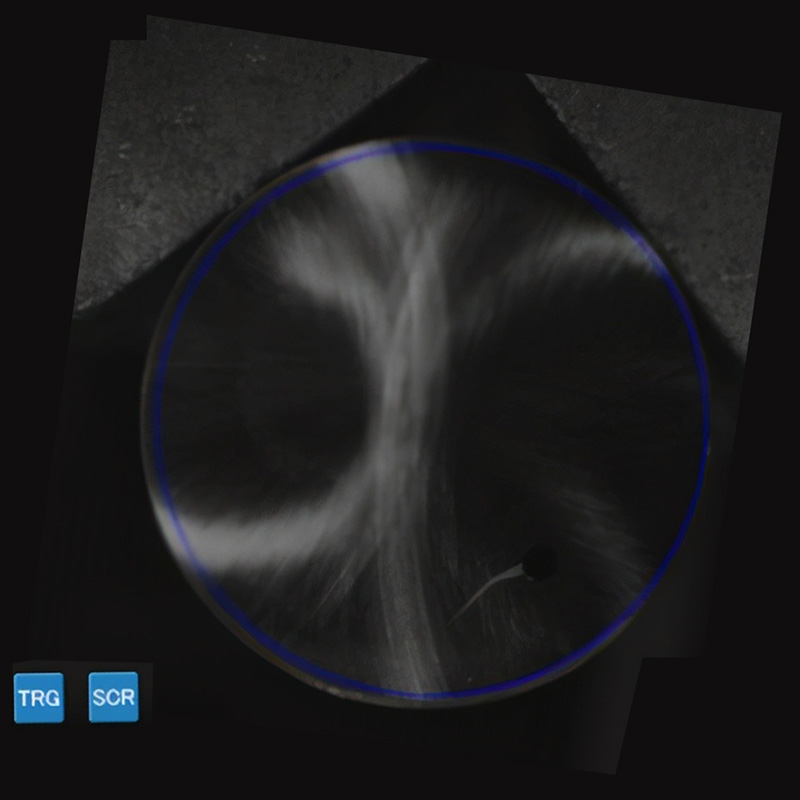

When capturing the image information of the precision hardware, as shown below, the color of the defect is almost the same as the background color, and the shape of the defect is not very different from the normal grain, which makes it difficult to identify the defect.

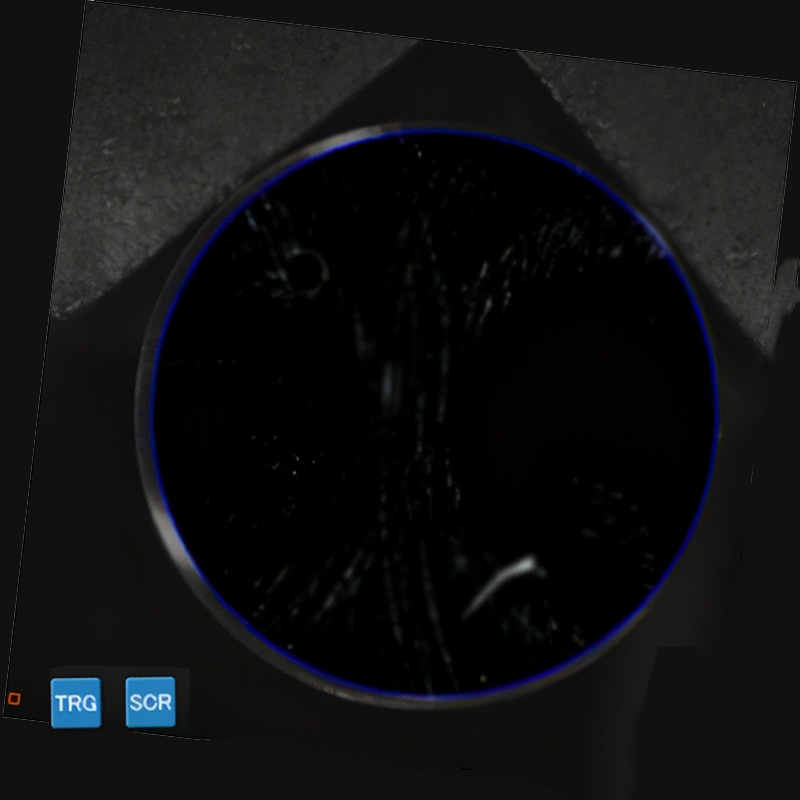

But after adding height information and background processing, the following effect is obtained. The corresponding defect can be clearly identified.

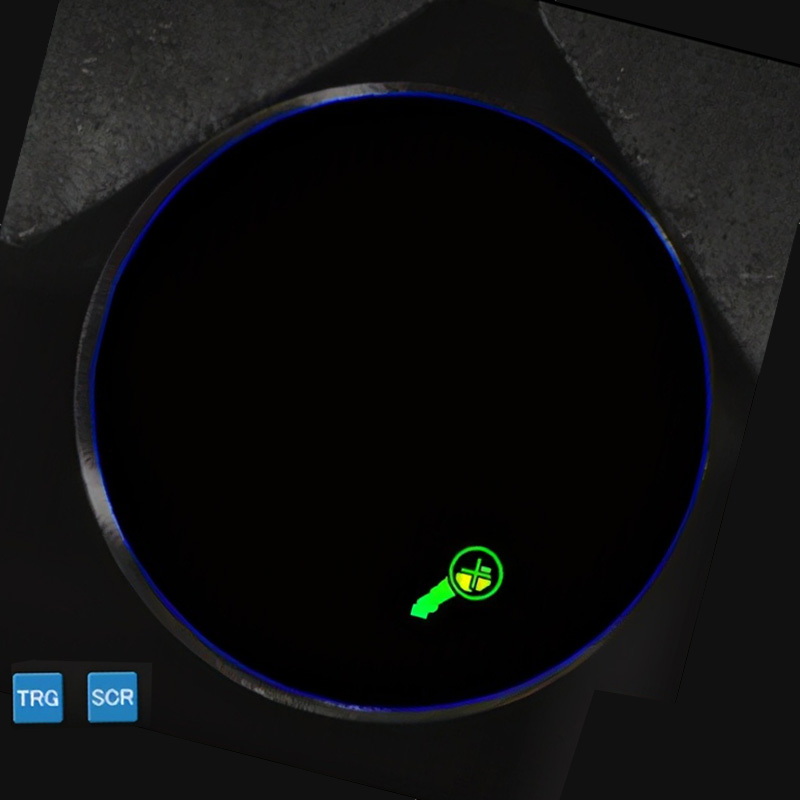

Defect 2: Edge missing

After adding height information, depending on the height difference, the position of the missing edge can also be reliably detected.

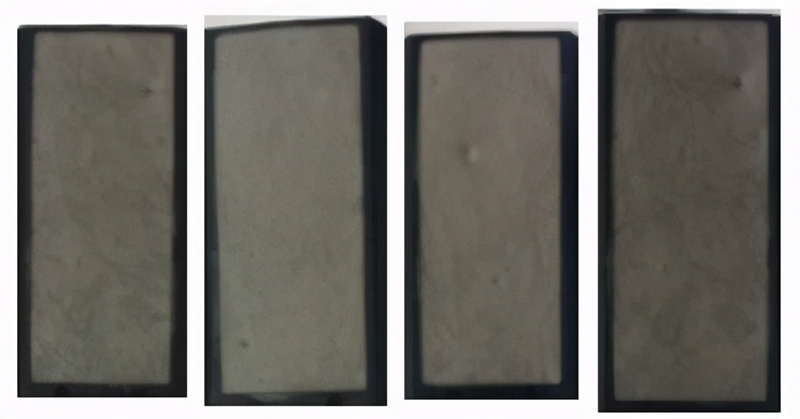

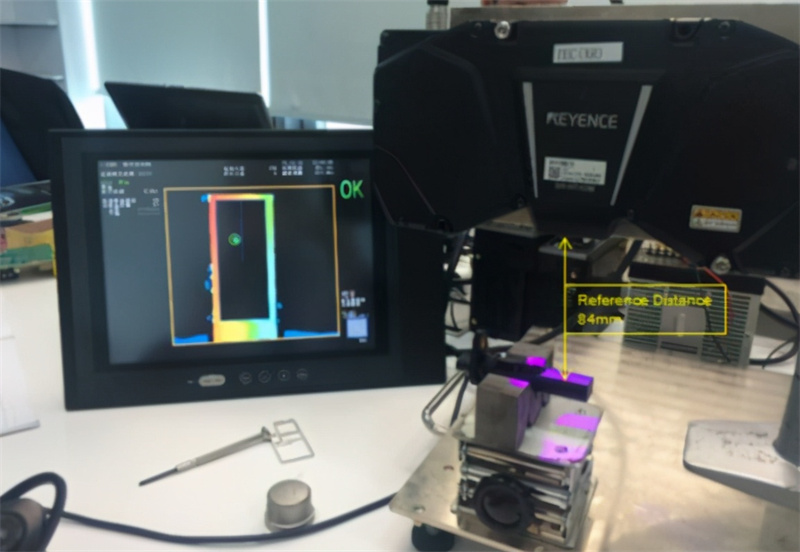

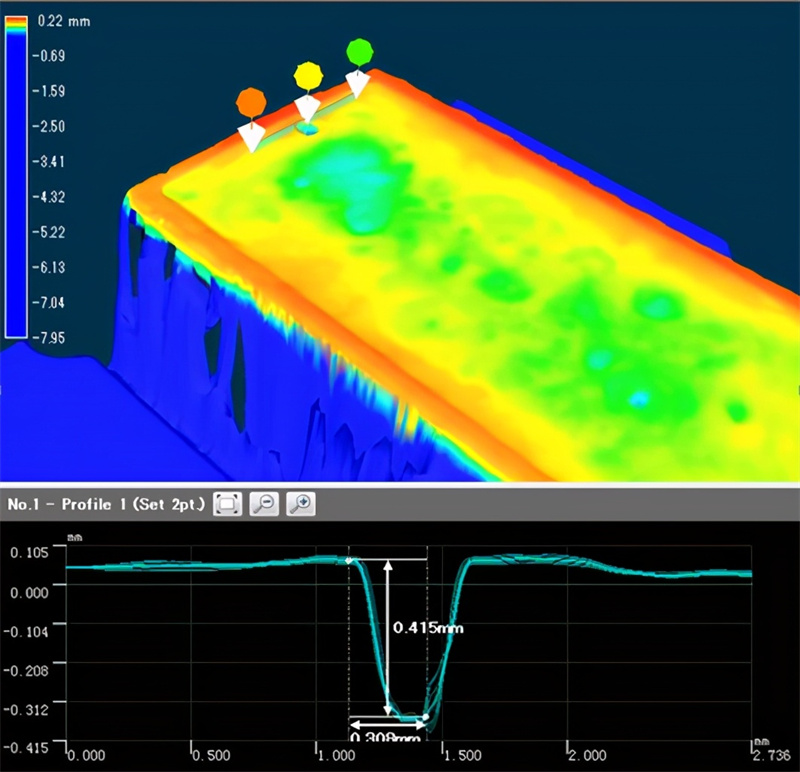

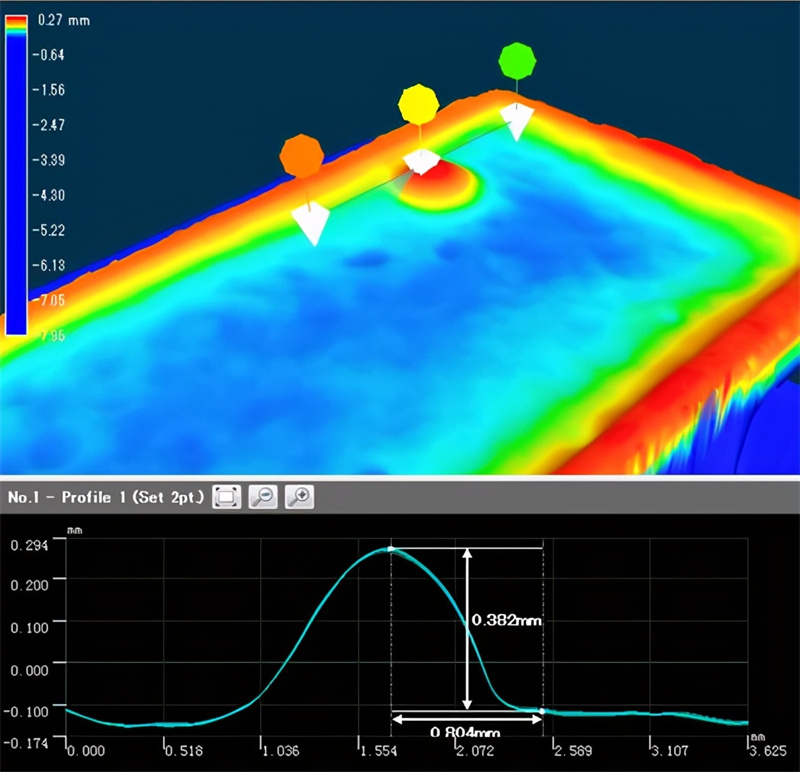

Case 2: Defects detection of waterproof adhesive

The waterproof adhesive on surface of the product in the picture below is defective in several places, both dented and protruding. These types of defects can easily lead to the failure of the waterproof effect, so it must be detected. This is because the dents and protrusions are the same as the product’s base color. It is not possible to detect it stably with a normal flat camera. But this problem can easily be solved by using a 3D Smart Camera. KEYENCE 3D Smart Camera is used for the following inspections.

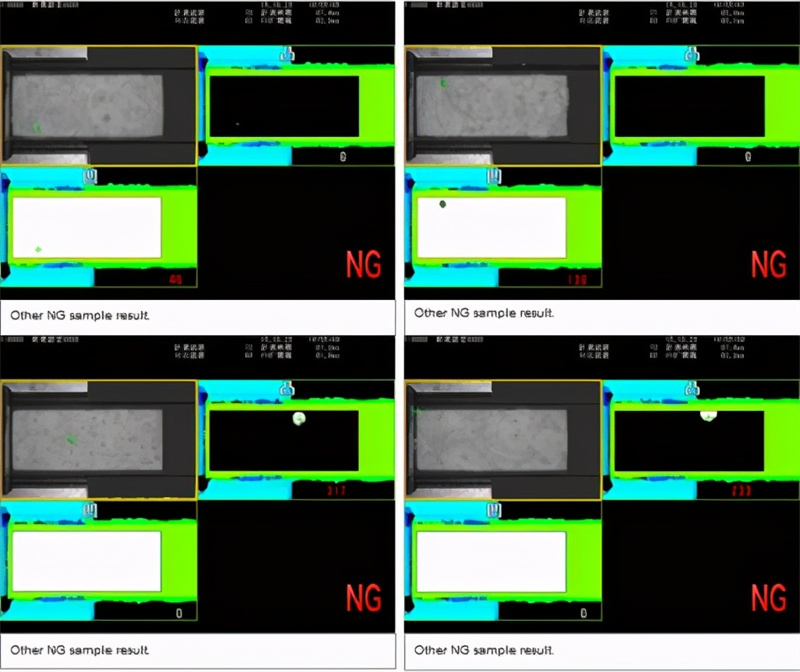

Detection effect image:

Dented effect image:

Protruding effect image:

Effect image of different defects be detected: