Castings are essential in engine manufacturing. Among engine parts, castings accounted for about 35%, casting product quality directly affects the performance of engine products.

There are many uncontrollable factors in the casting manufacturing process, casting defects are difficult to avoid. At present, the detection of surface defects in castings is still mainly based on manual inspection. Due to the large output of castings and subtle surface defects, manual inspection has the advantages of poor quality, low efficiency, high cost.

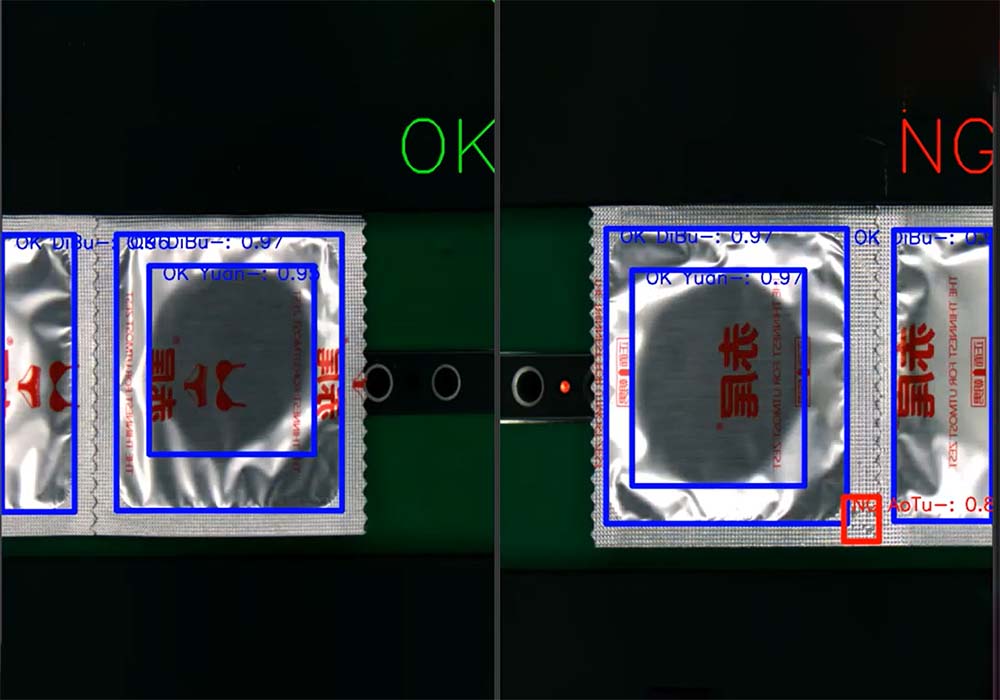

With the rapid development of computer and communication technology, machine vision technology has made great progress, especially the combination of machine learning algorithms and digital image processing technology, which provides a powerful help for solving complex vision-based inspection technology. Therefore, it is feasible, practical and efficient to use machine vision technology instead of manual detection of casting surface defects.

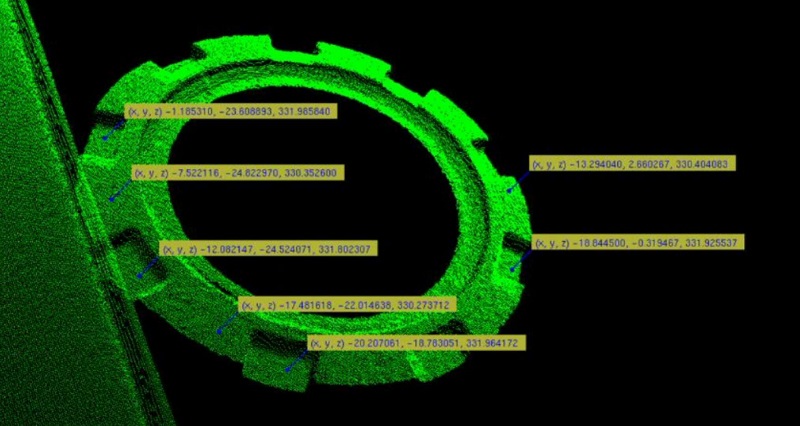

Detected requirements: 3D vision defect detection for Casting Parts

Defects type on castings:

1. Gas cavity

2. Shrinkage

3. Crack

4. Surface pseudo defects

Analysis of surface defects

1. The shape of the gas cavity defect is nearly round, and since its surface is lower than the normal surface, the gray value in the image is lower, and the deeper the gas cavity depth, the lower the gray value in the image.

2. Shrinkage defects are irregular in shape and have a lower gray value in the image. Due to the roughness of the inner wall of the shrinkage hole, there may be a certain gray scale change in the image of the defective area.

3. Shape of the crack defect is narrow and long, and its depth is deeper than the other defects, which results in a lower grayscale value in the image and the edge of the defect is more obvious.

4. Pseudo-defective rust spots are irregular in shape and have a higher gray level than other defects due to the gray level change caused by the surface color, and usually have a larger defect area.

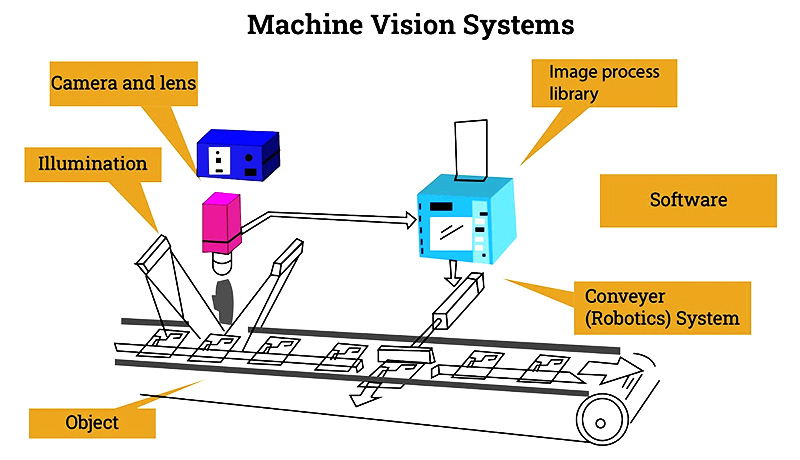

Critical parts of the detection machine:

1. Camera

Industrial cameras are used in this application. Industrial cameras commonly used in sensor chips are mostly CCD and CMOS, due to the CCD sensor in the effective light-sensitive area is larger, and the output image noise is relatively small, so the choice of CCD cameras. Because the detection object is castings, its surface is gray or high brightness, no color characteristics, so in order to reduce the amount of data and improve the efficiency of subsequent image processing, the choice of black and white CCD camera.

2. Lens

The lens is an optical element used to collect light to produce an image. Its selection is mainly based on the required lens magnification, focal length and other key parameters. These parameters are determined by the actual working distance, the size of the inspection object, the size of the camera phase element, and the inspection accuracy requirements.

3. Light source

The light source in the machine vision system is mainly used to provide a suitable and stable brightness, and tries to enhance the contrast between the part to be inspected and the surrounding environment. As the environment of the workshop where the inspection takes place is characterized by variable light, in order to avoid the vision system being affected by the external environment, the dark field lighting method is chosen. In the dark field environment, the light is completely provided by the light source, and the light source types applicable to the surface array camera include incandescent lamp, fluorescent lamp, LED and so on.

Among them, LED light source has the advantages of good stability, high luminous efficiency and long service life. Therefore, LED strip light source is chosen for illumination. Since the inspection target is surface defects, lighting should try to make the surface information of the inspection object more prominent. Therefore, frontal high angle lighting is chosen for illumination.

Function of casting surface detection machine:

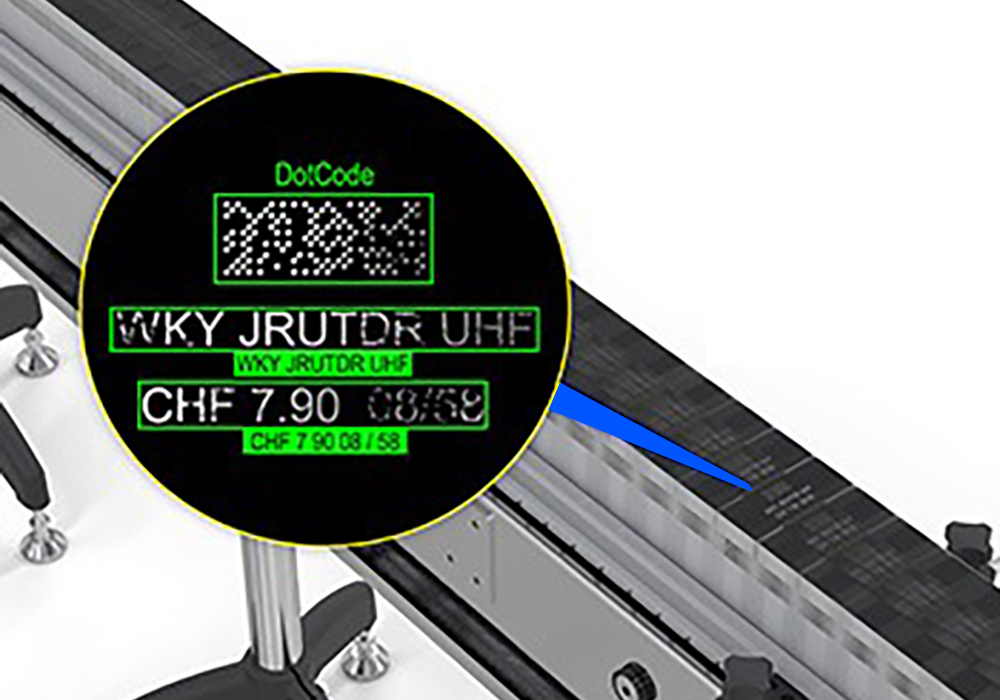

1. Real time display

Intsoft Software System interface should be able to display surface defect detection in real time, and can detect surface defects in castings and defects in the identification and classification of the results of the visual display interface, so that operators can understand the status of the inspection system.

2. Defective alarm prompts

When a defective product is detected, the visual inspection software should be able to signal a defective product in time for the actuator to take the next step.

3. Data record

Intsoft Software System has a real-time data storage function, can record the number of detected castings and qualified castings, as well as the number of different types of defects, and record the start and end time of each inspection and the detection of individual castings time consuming to generate a product inspection log, to facilitate subsequent analysis of retrospective analysis, improve the production process.