It is difficult to avoid various defects in the manufacturing process of the screen of a cell phone or pad, such as Bright spots, Black spots, Line defects, Pixel defects. So, how to avoid these defective screens flowing into the market?

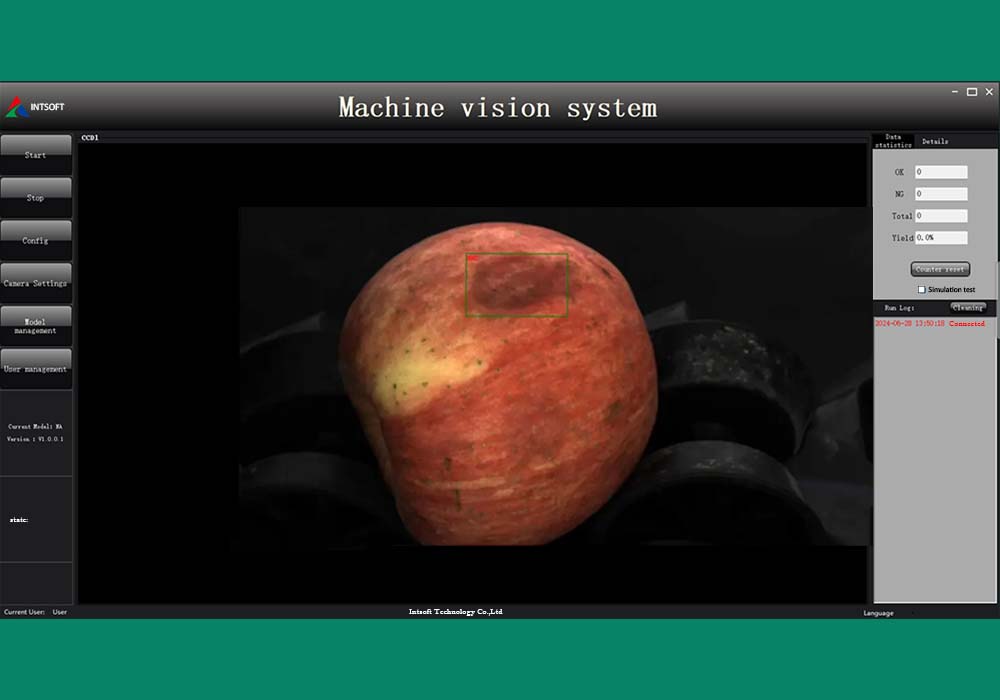

Machine vision, or automated optical inspection (AOI), is a widely adopted approach to detecting defects on phone screens during the manufacturing process. This technology leverages advanced image processing and computer vision algorithms to identify and classify various types of screen defects. Its main procedures include image acquisition, image processing, defect detection and classification, and reporting.

Machine vision inspection has unparalleled advantages over traditional inspection with the human eye, such as:

1. Increased accuracy and consistency: Machine vision systems can detect and classify defects with high precision, reducing the risk of human error.

2. Faster inspection and higher throughput: Automated inspection can be performed much faster than manual visual inspection, improving overall production efficiency.

3. Objective and quantitative analysis: Machine vision provides numerical data and metrics on detected defects, enabling more informed decision-making.

4. Continuous monitoring and process improvement: Data from the machine vision system can be used to optimize the manufacturing process and reduce defects over time.

The integration of machine vision technology has significantly enhanced the quality control and testing processes for phone screens, ensuring that end-users receive high-quality displays with minimal defects.

If you have similar product inspection needs, but don’t know how to realize it, try to find the machine vision integrator – Intsoft Technology to find out. With years of experience in the industry, we can provide you with professional advice.