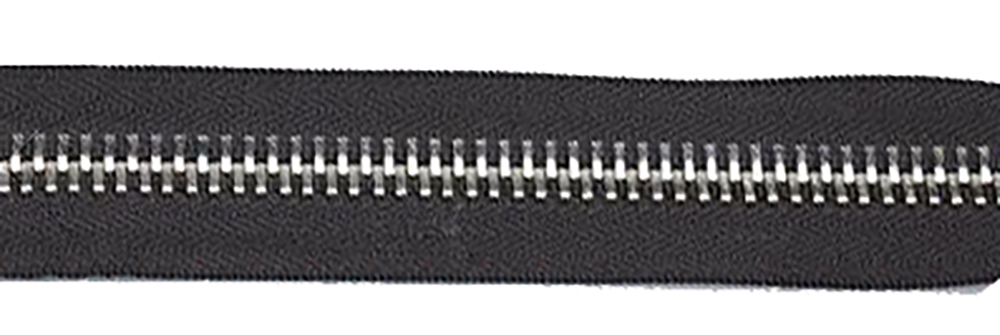

Sometimes after using the toilet, you pull up your pants and zip up to leave, but find that the zipper of your pants can’t be zipped up. It happened often when I was young, but it has almost never happened in recent years. Why is this? Because the quality of our zippers has improved a lot, and they are not as easy to get stuck with as before.

This is also helped by machine vision zipper defect detection.

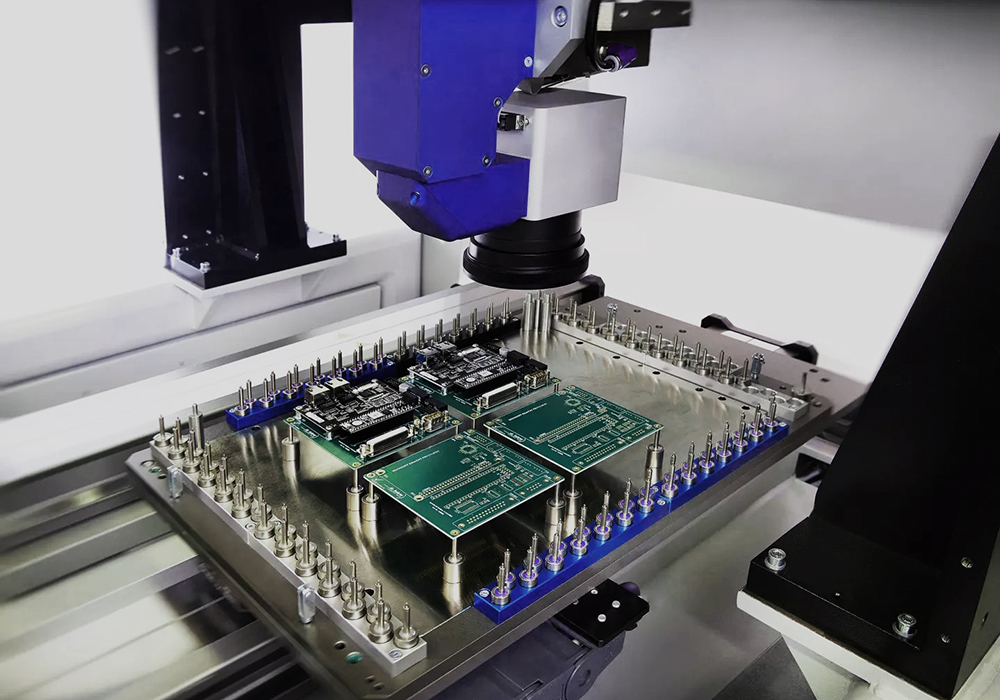

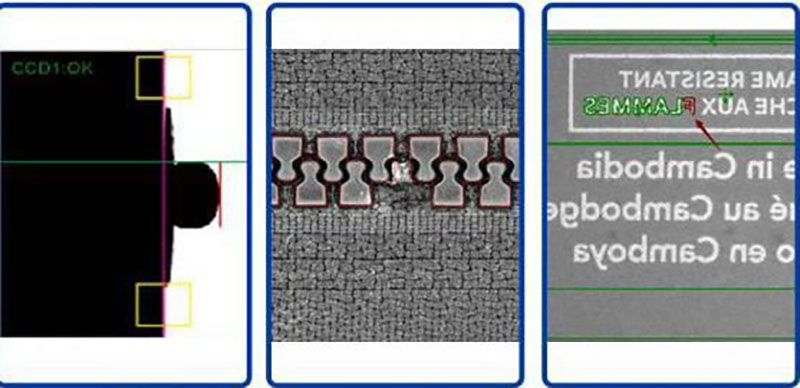

Machine vision is used to replace human eye inspection applications to collect, process, calculate, analyze, and evaluate images from real objects. According to pixel distribution, brightness, color and other information, the image processing software system performs various analyses to extract features, and then controls the operation of the equipment on site based on the judgment results to eliminate unqualified products.

The following are some of the zipper defects:

Dimensions: hole height, length, width, angle, length of inner diameter and outer diameter.

Damage: Diameter deformation, uneven nozzle, burrs

Coloring: contamination, inconsistent color, cross-coloring,

Coating: Zinc coating faded

Pattern: Missing characters and colors