Machine vision technology has been widely used in the industrial field, but its application in the fruit industry is relatively rare. As the demand for intelligent sorting in the fruit industry is gradually increasing and labor costs are rising, it takes a huge amount of resources to classify defective, ordinary and high-quality fruits. In order to save costs and improve efficiency, many fruit-related companies have found us and requested to customize some fruit defect recognition and sorting equipment. The following is a classic case of orange defect detection shared by Intsoft Technology.

Vision Detect Items: Orange quality inspection

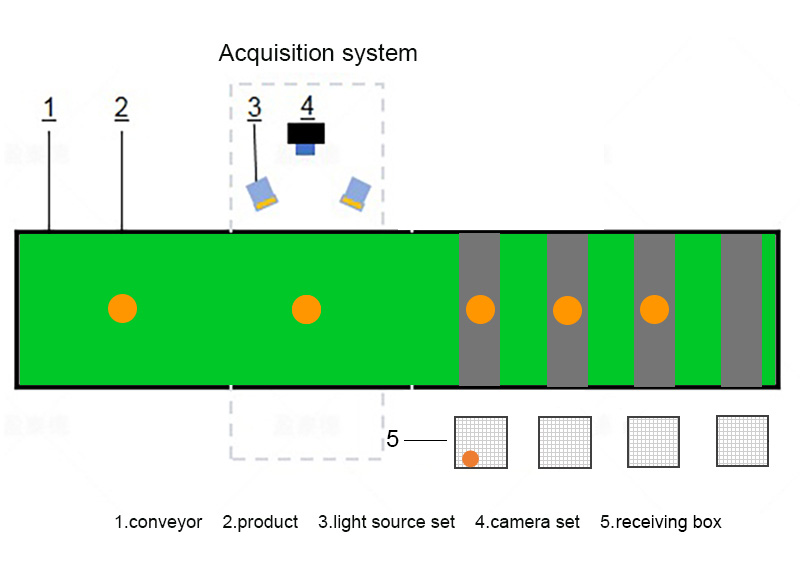

Machine vision equipment workflow:

- Enter the basic information of the product, model the OK product, collect images for preprocessing, extract key features of the images that meet the algorithm requirements, and establish an image data set.

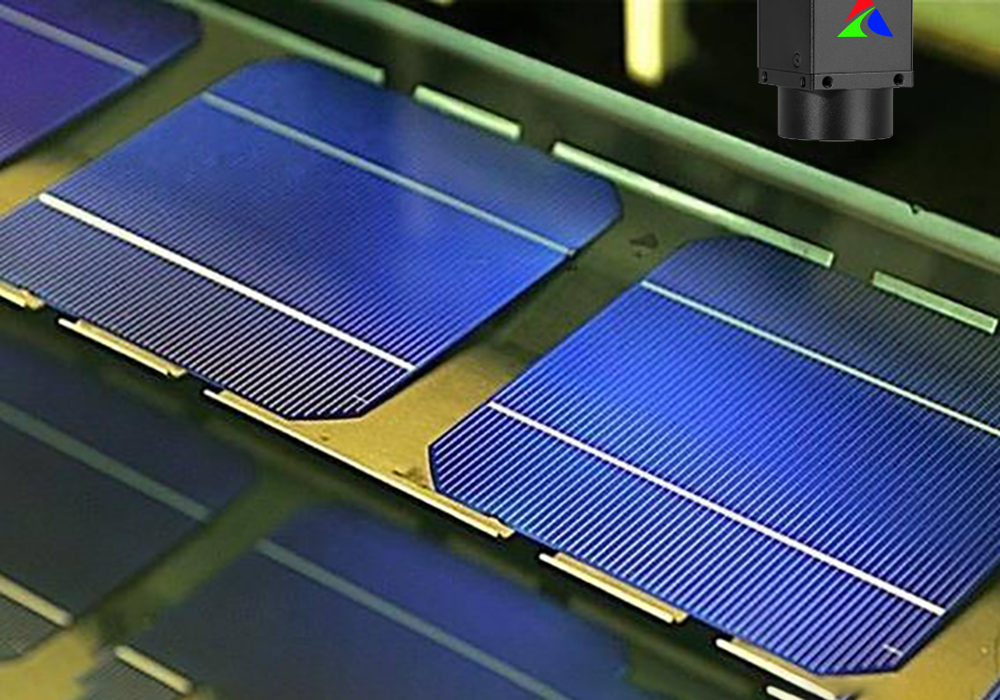

- Install the camera at a fixed position, and the product moves along the inspection line. When it reaches the position of the photoelectric sensor, a trigger signal will be generated immediately. The camera collects the image and uploads it to the database.

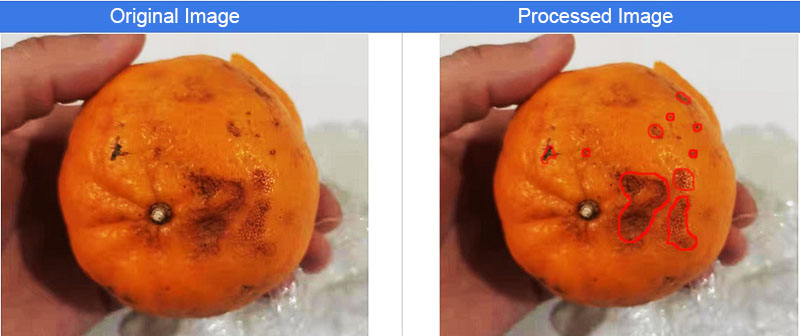

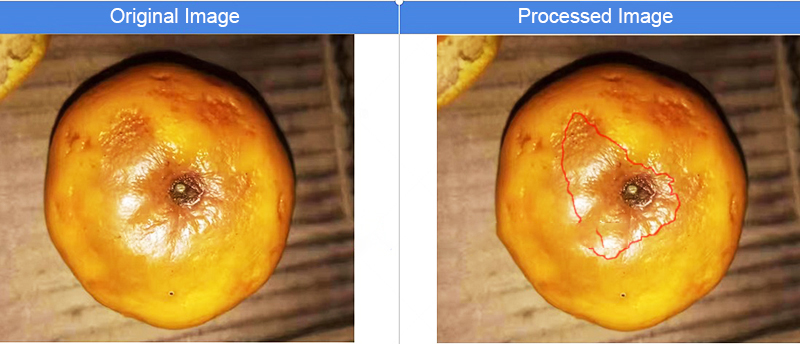

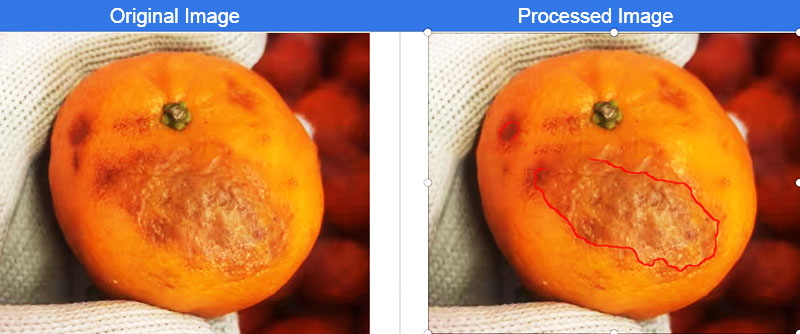

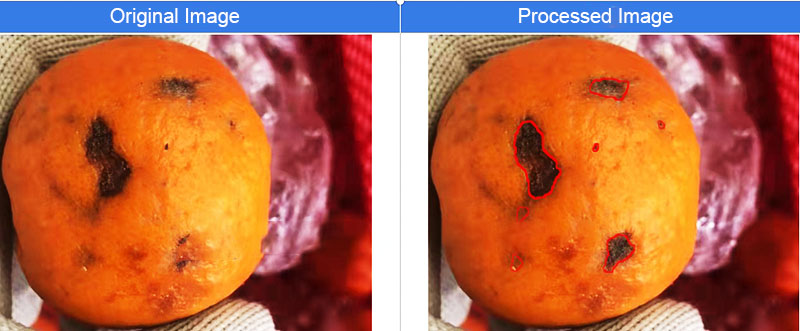

- The collected images are processed by Intsoft Technology’s intelligent image processing algorithm to judge good/bad products, and the interface outputs inspection information in real time. Pack the good/bad products into the material box.

The collected image:

Machine vision system functions:

- 1. When the system detects a defect, it outputs an alarm signal.

- 2. Real-time information display and record detection information.

- 3. Provide special tools such as system parameter adjustment and image saving. The system interface is friendly, operable and intuitive.

- 4. In order to ensure data security, the system is equipped with permission management. Only administrators with permission can modify the corresponding system parameters.

- 5. According to the selected product inspection items, match the inspection program, and the inspection area can be adjusted according to the actual situation.

- 6. The inspection history records can be automatically counted, saved, queried, called, etc.

- 7. Automatic linkage of production lines, remote technical services, etc.