The purpose of inspection of ointment packaging is to control packaging quality and prevent ointment with package problems from entering the market. At present, most ointment inspection companies still use manual monitoring for inspection, but this method has problems such as high labor intensity, low inspection accuracy and irregular management, and the inspection results cannot meet expectations. Therefore, some large pharmaceutical companies have begun to introduce automatic detection equipment to implement real-time online detection of ointment packaging, which can repeatedly inspect ointment packaging in large quantities, and at the same time, the accuracy and standardization can be greatly improved.

Detection process:

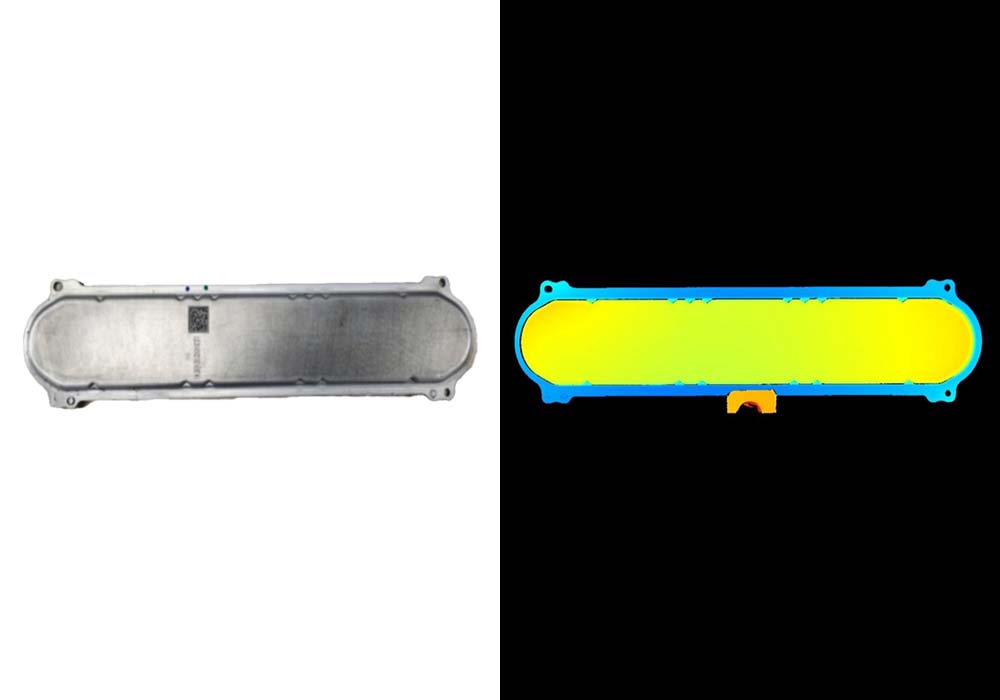

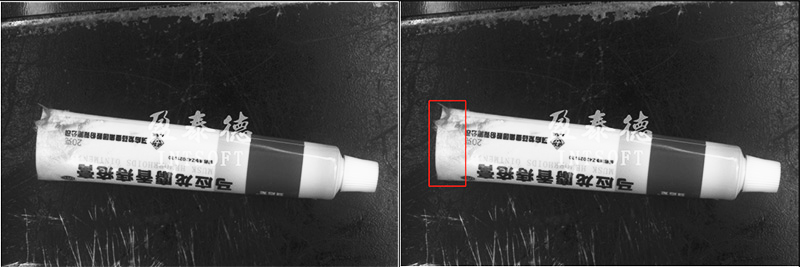

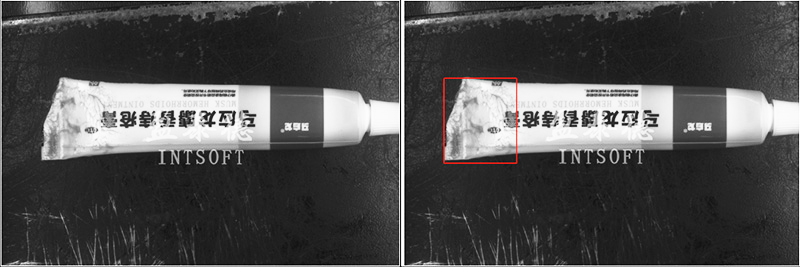

Ointment sealing defect detection

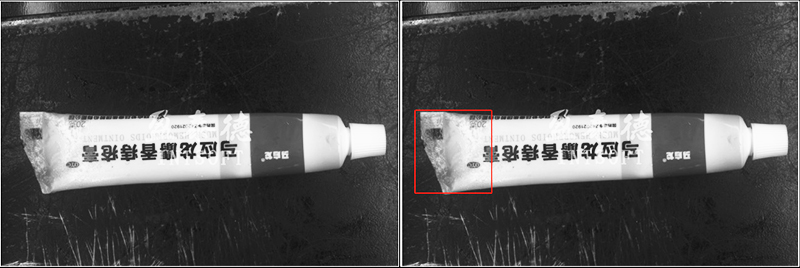

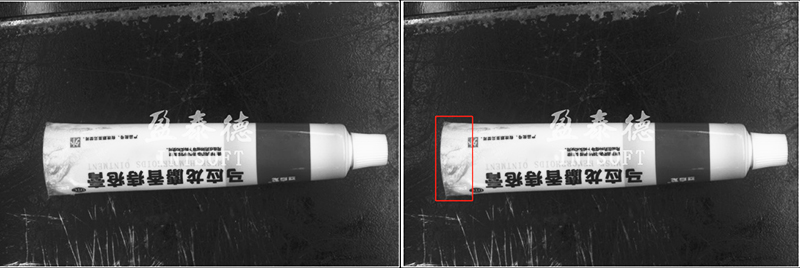

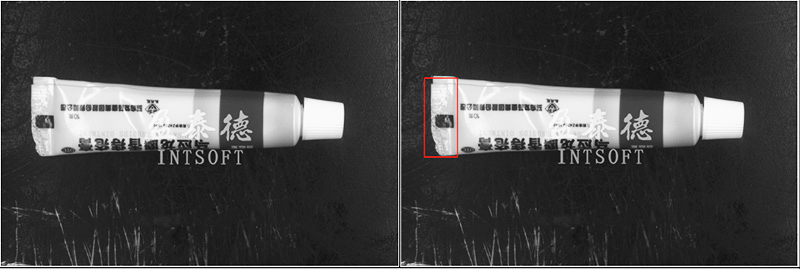

The left side is the original image acquisition, and the right side is the corresponding vision detection processing result.

Machine vision inspection application on medicine industry, like ointment package surface defect detection mainly inlude the following aspects:

1. Defect Detection: Machine vision systems can be used to inspect ointment packages for defects such as dents, cracks, label misalignment, or other visual imperfections. This can help ensure product quality and consistency.

2. Seal Inspection: Cameras can be used to verify that ointment package seals are properly formed and intact, reducing the risk of leaks or contamination.

3. Content Level Monitoring: Machine vision can track the filling level of ointment in the package, ensuring the correct amount is being dispensed.

4. Barcode/Label Reading: Cameras can read barcodes, text, or other label information on ointment packages, facilitating inventory management, tracking, and logistics.

5. Closure Verification: Machine vision can confirm that the correct closure (cap, lid, etc.) has been properly applied to the ointment container.

6. Particle Detection: Cameras can inspect ointment packages for unwanted particles or foreign matter that could compromise product quality.

7. Tamper Evidence Inspection: Machine vision can verify that tamper-evident seals or features on the ointment packaging are intact, assuring the customer of product safety.