In today’s fast-paced industrial landscape, the demand for automation and precision has never been higher. As manufacturers strive for efficiency and quality, the role of machine vision systems has become increasingly vital. Among the leaders in this sector is Intsoft Tech, a company known for its turnkey systems integration solutions. This article delves into Intsoft Tech’s significance in the machine vision integration space, exploring its offerings, technology, and impact on various industries.

1. Understanding Turnkey Systems Integration

What is Turnkey Systems Integration?

Turnkey systems integration refers to the process in which a company provides a complete solution to a client, from design and development to installation and support. This approach allows companies to implement complex systems without the need for in-depth technical knowledge or resources.

Importance in Industry

The turnkey approach is particularly beneficial in industries that require seamless integration of various technologies. It ensures that all components – hardware, software, and processes – work together efficiently. This integration reduces downtime, increases productivity, and minimizes the risk of errors during implementation.

2. Intsoft Tech: A Leader in Machine Vision Integration

Company Overview

Founded in 2014, Intsoft Tech has established itself as a leading provider of machine vision integration solutions. With a focus on innovation and customer satisfaction, the company has successfully completed numerous projects across a variety of industries, including automotive, pharmaceuticals, food and beverage, and electronics.

Mission and Vision

Intsoft Tech’s mission is to empower businesses with advanced technology solutions that enhance operational efficiency and product quality. The company envisions a future where automation and intelligent systems are integral to manufacturing processes.

3. Intsoft Tech Core Offerings

Machine Vision Solutions

Intsoft Tech specializes in machine vision systems that leverage advanced imaging technologies to perform tasks such as inspection, measurement, and identification. Their solutions are designed to improve quality control and streamline manufacturing processes.

Custom Integration Services

One of of Intsoft Tech’s distinguishing features is its ability to provide tailored integration services. The company works closely with clients to understand their unique needs and develop custom solutions that seamlessly fit into existing workflows.

Software Development

Intsoft Tech also excels in software development, creating custom applications that enhance the functionality of machine vision systems. This includes integrating machine learning algorithms to improve defect detection and analysis.

Technical Support and Training

To ensure the successful implementation of their systems, Intsoft Tech offers comprehensive technical support and training services. Their team of experts provides ongoing assistance to clients, helping them maximize the benefits of their machine vision solutions.

4. The technology behind Intsoft Tech’s solutions

Advanced Imaging Systems

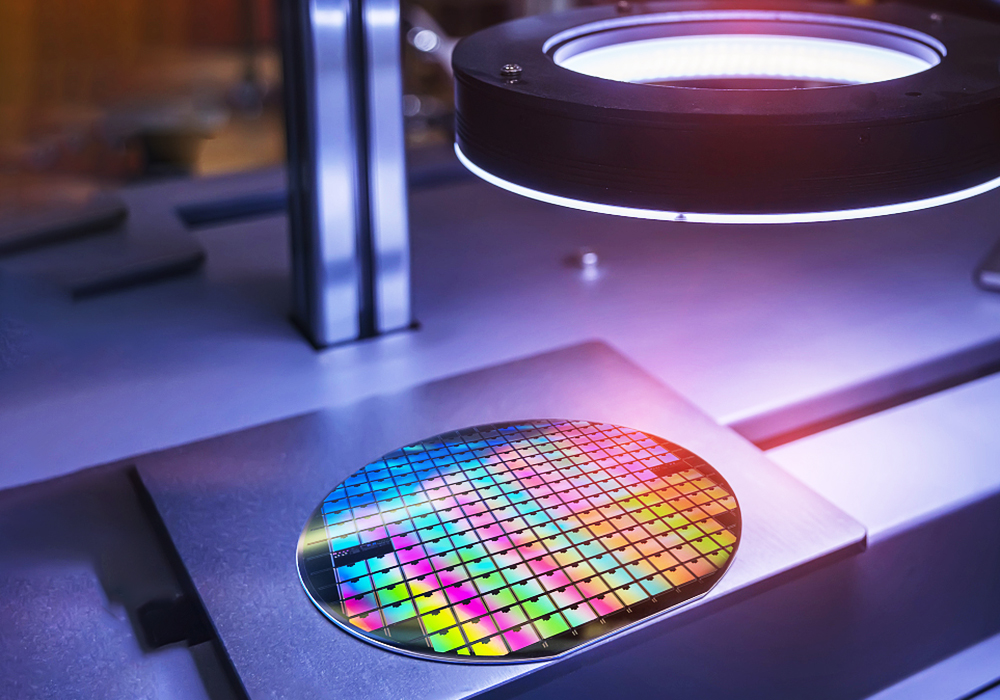

Intsoft Tech employs state-of-the-art imaging technologies, including high-resolution cameras and specialized lighting systems, to capture detailed images for analysis. These technologies are critical for tasks such as defect detection and measurement.

Machine Learning and AI

The integration of machine learning and artificial intelligence is a game-changer in machine vision. Intsoft Tech uses these technologies to improve the accuracy and speed of inspections, enabling systems to learn from data and improve over time.

Real-time data processing

Intsoft Tech’s solutions are equipped with real-time data processing capabilities, allowing immediate analysis and feedback. This feature is essential for industries where rapid decision-making is critical, such as food safety and pharmaceuticals.

User-friendly interfaces

Ease of use is a priority for Intsoft Tech. Their systems come with intuitive interfaces that allow operators to monitor processes and make adjustments effortlessly, reducing the learning curve and increasing productivity.

5. Industry Applications

Automotive Sector

In the automotive industry, precision and reliability are paramount. Intsoft Tech’s machine vision solutions help manufacturers identify defects in parts and assemblies, ensuring that only the highest quality components make it to production lines.

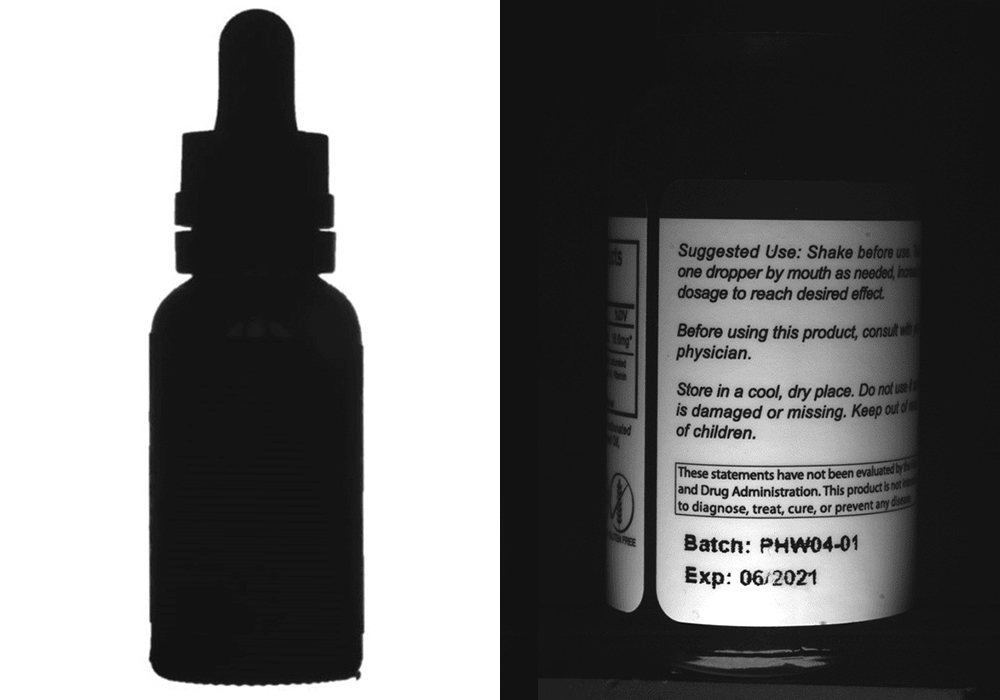

Pharmaceutical Industry

Quality control in pharmaceuticals is critical to ensuring patient safety. Intsoft Tech provides solutions that inspect packaging integrity, label accuracy, and dosage consistency, helping companies comply with stringent regulatory standards.

Food and Beverage Industry

Food safety is a major concern in the food and beverage sector. Intsoft Tech’s systems can detect foreign objects, monitor packaging integrity, and ensure labeling accuracy, contributing to safer products for consumers.

Electronics Manufacturing

The electronics industry demands high precision and efficiency. Intsoft Tech’s machine vision solutions assist inspect circuit boards and components, identifying defects that could compromise product performance.

6. Case Studies

Automotive Quality Control

In a recent project with a major automotive manufacturer, Intsoft Tech implemented a comprehensive machine vision system to inspect components on the assembly line. The system successfully reduced defect rates by 30%, significantly improving overall product quality.

Pharmaceutical Packaging Inspection

Intsoft Tech has partnered with a pharmaceutical company to enhance its packaging inspection processes. By integrating advanced imaging technologies, the company was able to identify packaging defects in real-time, resulting in a 25% increase in operational efficiency.

Food Safety Solutions

A leading food manufacturer has partnered with Intsoft Tech to develop a machine vision system for detecting foreign objects in packaged goods. Implementing this system not only improved safety, but also reduced product recalls by 40%.

7. Competitive Advantage

Expertise and Experience

Intsoft Tech boasts a team of experienced professionals with deep knowledge of machine vision and automation technologies. This expertise allows them to deliver high-quality solutions that effectively meet client needs.

Customer-Centric Approach

The company’s commitment to understanding and addressing customer challenges sets it apart from competitors. Their tailor-made solutions and ongoing support ensure that clients can maximize the benefits of their investments.

Innovative Solutions

By continuously exploring and adopting emerging technologies, Intsoft Tech remains at the forefront of machine vision integration. Their focus on innovation ensures that they can provide cutting-edge solutions that enhance efficiency and quality.

8. Future trends in machine vision integration

Increased adoption of AI and machine learning

As machine learning and AI technologies continue to advance, their integration into machine vision systems will become more prevalent. Intsoft Tech is well positioned to leverage these technologies for improved inspection and analysis.

Growth of Smart Manufacturing

The push toward smart manufacturing will drive demand for machine vision solutions that can connect with IoT devices and other automation systems. Intsoft Tech’s integration expertise will be critical in this evolving landscape.

Enhanced Data Analytics

The future of machine vision will likely involve more sophisticated data analytics capabilities. Intsoft Tech aims to integrate advanced analytics into their systems, providing clients with deeper insights into their operations.

9. About Intsoft Tech

Intsoft Tech stands out as a leading international turnkey systems integrator in the machine vision integration space. With a commitment to quality, innovation, and customer satisfaction, the company continues to empower businesses across a variety of industries. As the demand for automation and precision grows, Intsoft Tech is poised to remain at the forefront of this transformative field, helping manufacturers achieve their goals through advanced machine vision solutions.