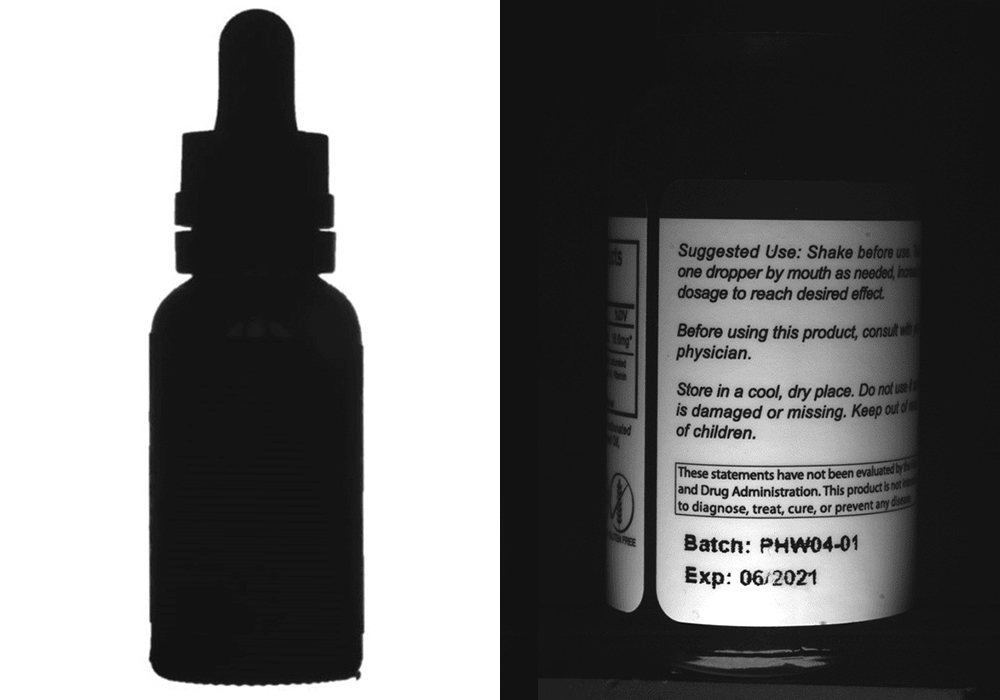

Due to the special nature of pharmaceutical products, the information on the drug bottle label is directly related to the safety of the patient’s medication, and any error may have serious consequences. At the same time, labeling must also comply with industry regulations and the various conditions for the marketing of drugs. In addition, labeling information is also an important basis for drug quality traceability, helping to quickly identify defective products and take action.

Therefore, the labeling inspection rate on drug bottles is required to be 100%. And to achieve inspection on a high-speed production line, it is impossible to achieve by manual inspection. In response, Intsoft Tech developed a visual inspection system to detect the presence/absence of labels on drug bottles, which has been widely used in major pharmaceutical plants, with a speed of up to 12,000 bottles per hour.

Following is the drug bottle label inspection case share by Intsoft Tech.

Detection configuration:

1. Use 1.2 million high-speed industrial camera, Gigabit network interface, stable data transmission.

2. Adopt 8mm fixed focal length industrial lens, can capture the full resolution of megapixel camera, low deformation rate (less than 1.0%), focus and aperture locking adjustment screws, high contrast and clarity images throughout the screen range.

3. Using 120mm LED ring light source: AFT-RL series LED ring light source is composed of high brightness and long life LED light emitting tubes, which evenly illuminate the surface of the object.

4. 14-inch touch-sensitive integrated industrial computer processor, 2*Gigabit network ports, 8-input and 8-output I/O card, RS232\485 interface, Intel Core I7, 3rd generation desktop processor, dual-core four-thread, 3M cache, 3.3GHz main frequency, 2G memory, 500G mechanical hard disk.

5. Self-developed intelligent software.

System functions:

1. Automatic online detection with or without labels.

2. Automatic rejection signal output.

3. Real-time statistics of detection data to accurately record current production conditions.

System features:

1. Detection rate: 100%

2. The bottle in the workstation, no matter which direction the bottle is facing, can be correctly detected.

3. No contact will not cause 2 times pollution

4. High detection speed, up to 12,000 bottles / hour

5. Intsoft intelligent software, modular software operation, easy to learn, it is available for operators to get started in ten minutes learning!

6. Applicable to any shape label detection, according to different product models, the establishment of different project files, 10 seconds to switch the program.

7. Visualization monitoring, real-time visibility of the current production quality of the product.

8. The system can count the missing and defective types of drugs and capsules and the day of the defective batch, the detection data information can be docked enterprise industrial information system, can analyze the data to determine equipment failure locations.