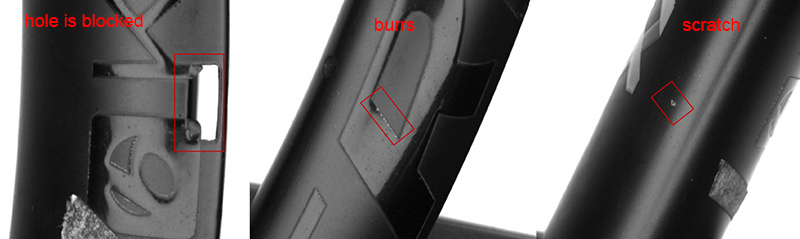

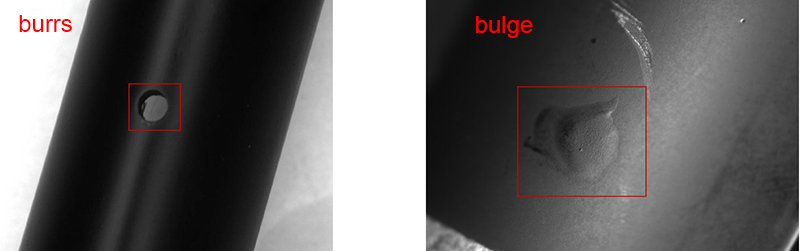

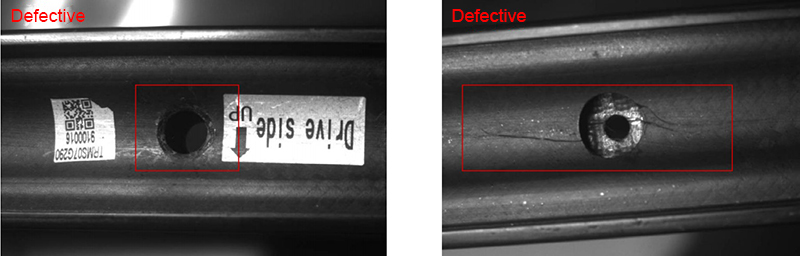

During the manufacturing process of industrial products, various appearance defects will occur, such as short shots, burrs, black spots, scratches, cracks, dirt, etc. In terms of the optical characteristics of the appearance visual inspection equipment, when light enters the surface of the product, various defects will show differences from the surrounding in terms of reflection, refraction, etc.

For example, when uniform light is incident vertically on the surface of the product, there are no defects on the surface of the product, the direction of emission will not change, and the detected light is also uniform.

When the surface of the product contains defects, the light emitted will change and the detected image will change accordingly.

Next, from Intsoft Technology, which focuses on the research and development and manufacturing of appearance visual inspection equipment, shows the solution of appearance machine vision inspection for bicycle wheel rim.

Bicycle Accessory Wheel Rim Visual Inspection Equipment Inspection Case

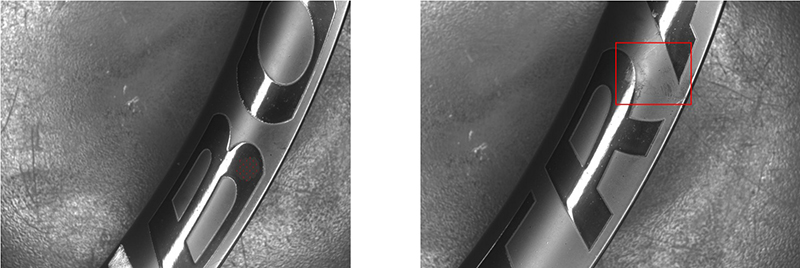

Stain:

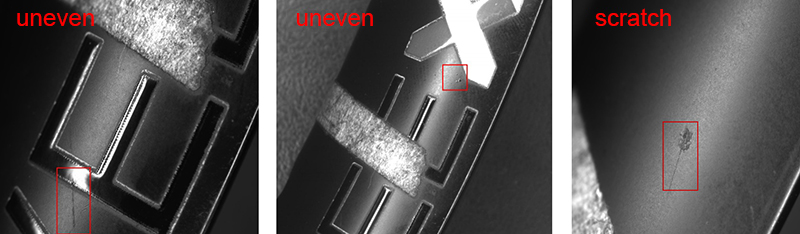

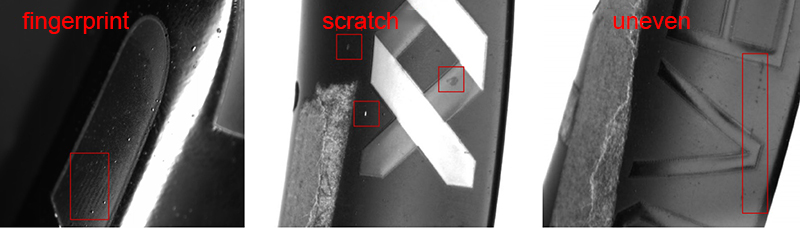

Various Type of Defect:

Solution:

- The rim is clamped by a mechanism, rotated 360 degrees, and 4 sets of scanning cameras are used to shoot the upper and lower end faces and the inner and outer surfaces of the rim at multiple stations.

- After AI intelligent recognition creates models for various types of defects, makes judgments and saves data through real-time collected images.

System installation requirements:

Inspection space for equipment placement: Install Intsoft Technology visual inspection system separately next to the assembly line, and make sure there is enough space to install the equipment.

Ambient temperature: 0-50 degrees Celsius;

Air humidity: below 90% RH;

Electronic interference: Provide a place with less electronic interference for the equipment.

Power supply: AC 220V, 50Hz, power consumption <1KVA