As electronic components are generally small and have strict environmental requirements, they cannot be detected in large quantities by hand, but only through customized machine vision inspection software.

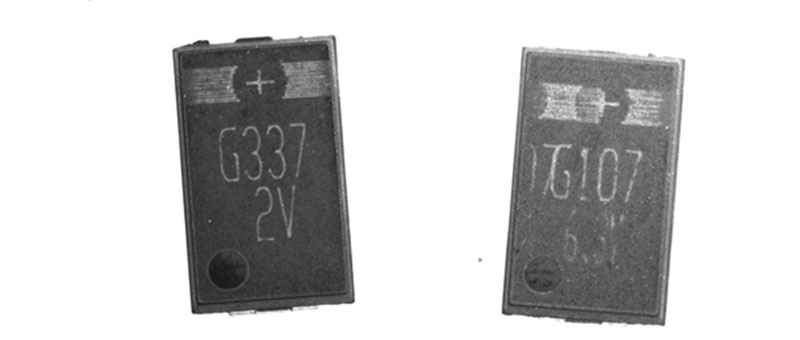

For example, the appearance of electrode defect detection, visual appearance inspection can detect items such as electrode size measurement and electrode dirt, peeling, chipping, yellowing, tilting. Body of missing corners, black spots, stained tin, etc. After visual defect detection, we can sort qualified and unqualified parts into different material areas through sorting equipment.

Inspection items:

Electrode size measurement and electrode dirt, peeling, chipping, yellowing, tilting. The body of missing corners, black spots, stained tin.

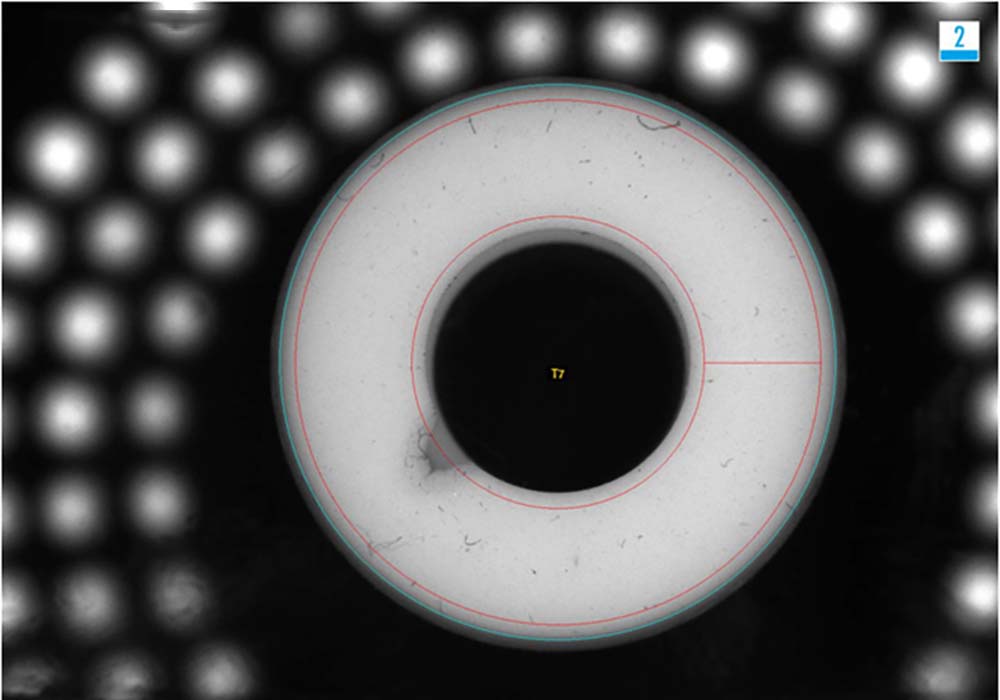

Dimensional Measurement

Appearance detection

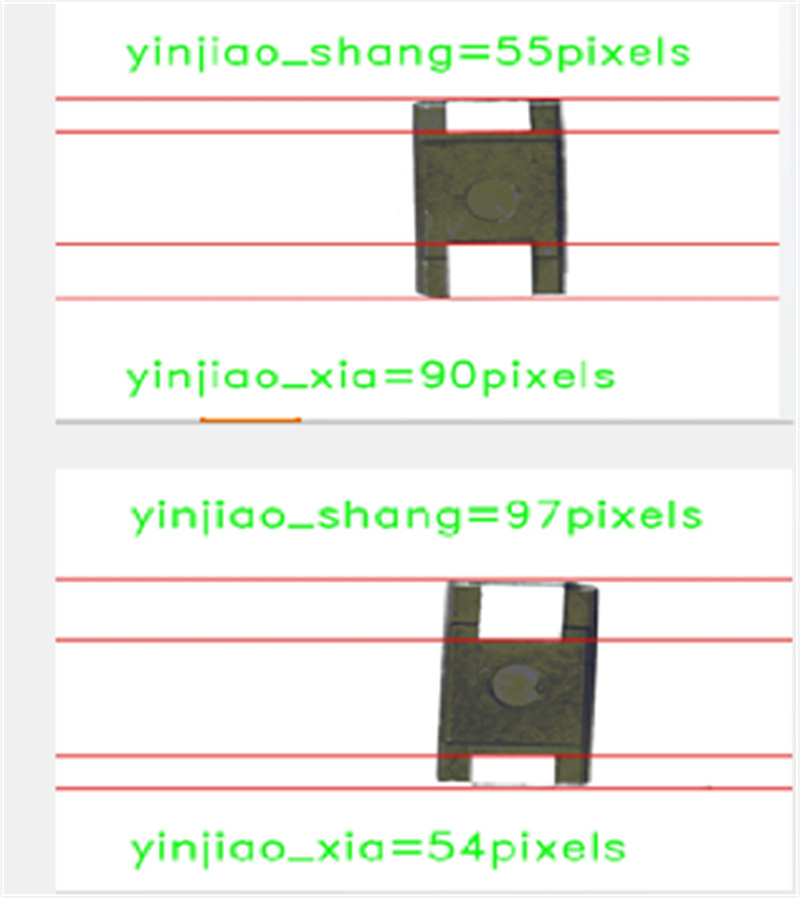

Incomplete printing, with or without printing:

Reversed printing or foreign matter on pins: