lithium batteries are a type of rechargeable battery source that has a cylindrical shape, typically resembling the size and form factor of traditional AA, AAA, or 18650 batteries. These batteries are commonly used in a wide range of applications such as consumer electronics, electric vehicles and energy storage systems, etc.

Lithium batteries have advantages such as high energy density, safety features, robustness, and cost-effectiveness. The versatility, safety, and cost-effectiveness of lithium batteries have made them a widely adopted solution for a variety of portable power applications in the consumer, industrial, and transportation sectors.

With such an important and widely used energy carrier, how do you ensure that they are cosmetically free of defects and avoid battery quality issues before they leave the plant?

Machine vision inspection is a must for today’s battery surface defects.

Following is Intsoft Technology machine vision defect detection equipment’s detection solutions.

Detection position

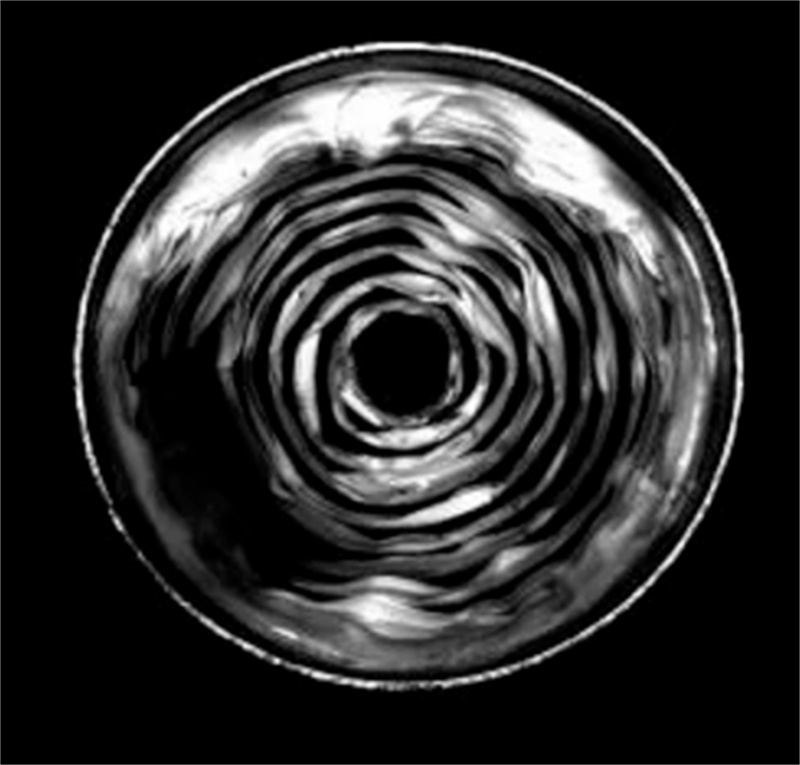

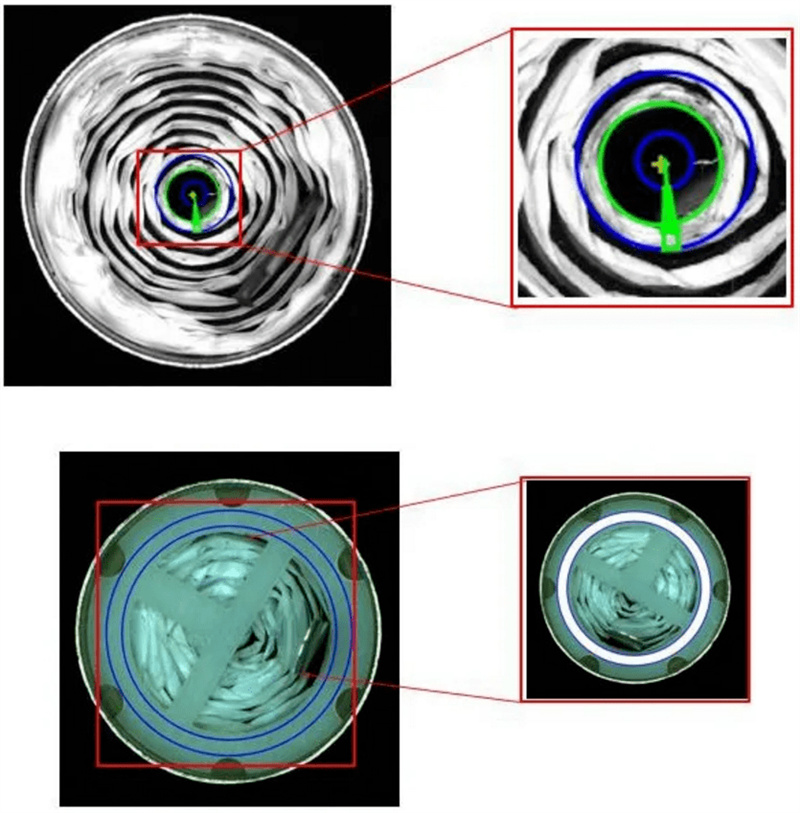

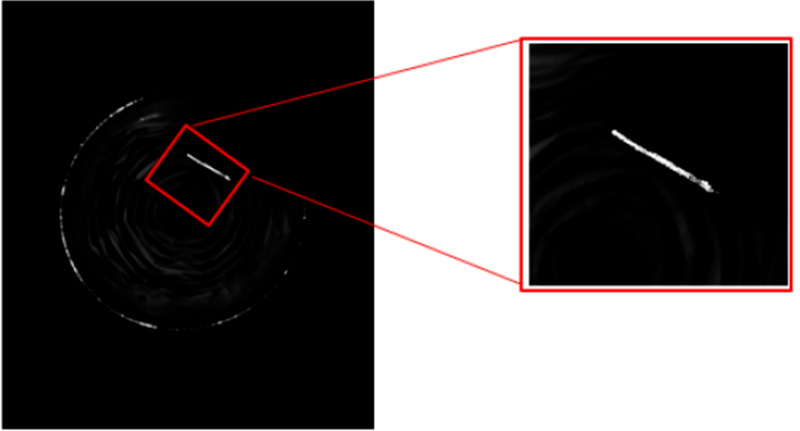

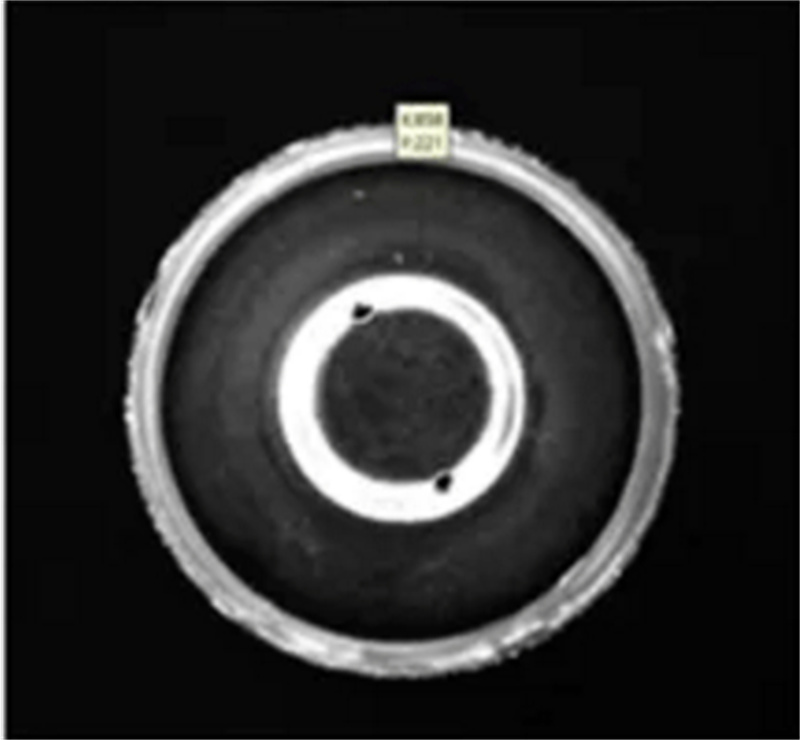

Bottom shell welding station inspection original image:

Detection requirements

1. Centre hole position

2. Centre hole detection

3. Correction angle

4. Positive insulation piece detection

Roll groove measurement

Detection requirements

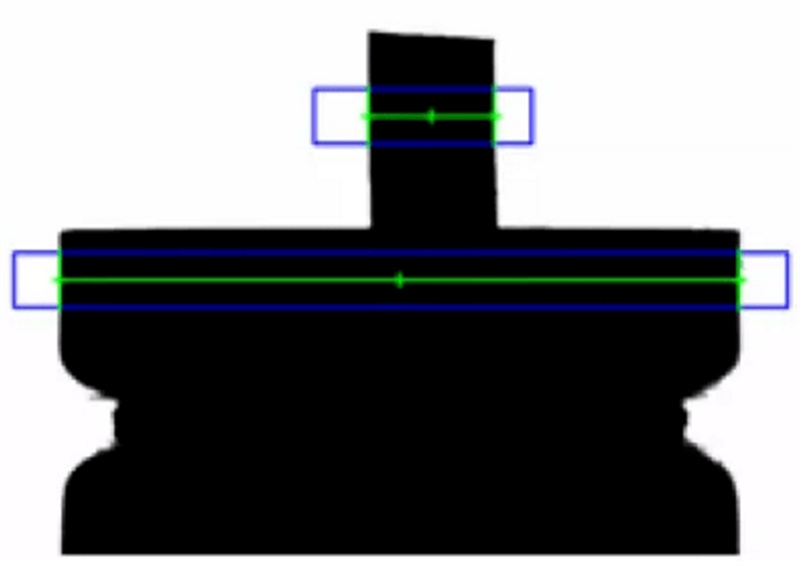

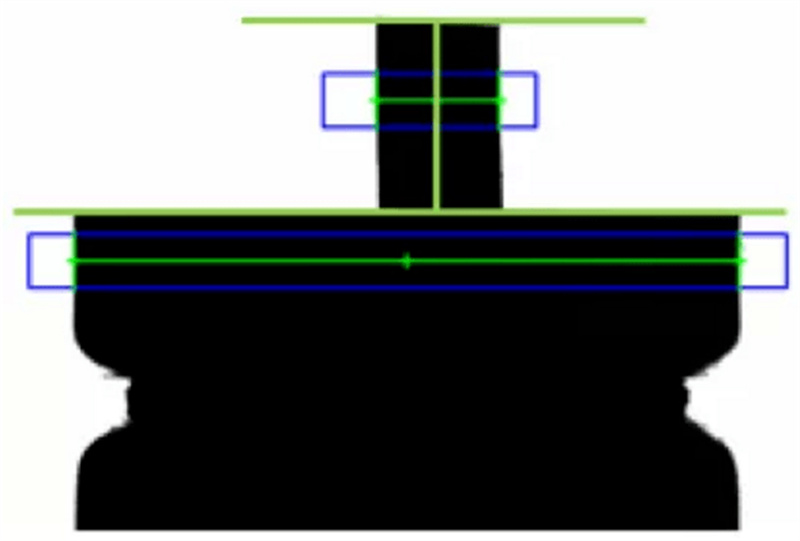

1. Inspection the size of roll groove

2. Inspection the spot glue on the roll groove with or without air bubbles, glue incoherence.

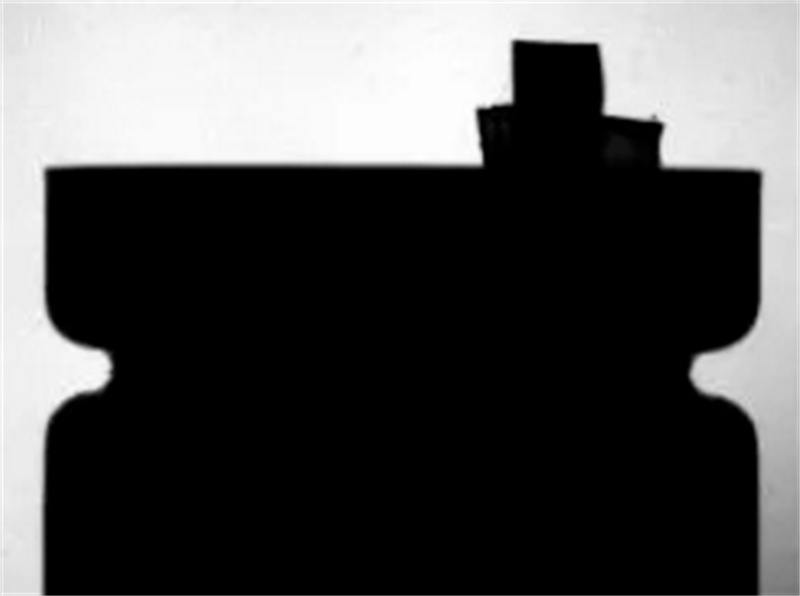

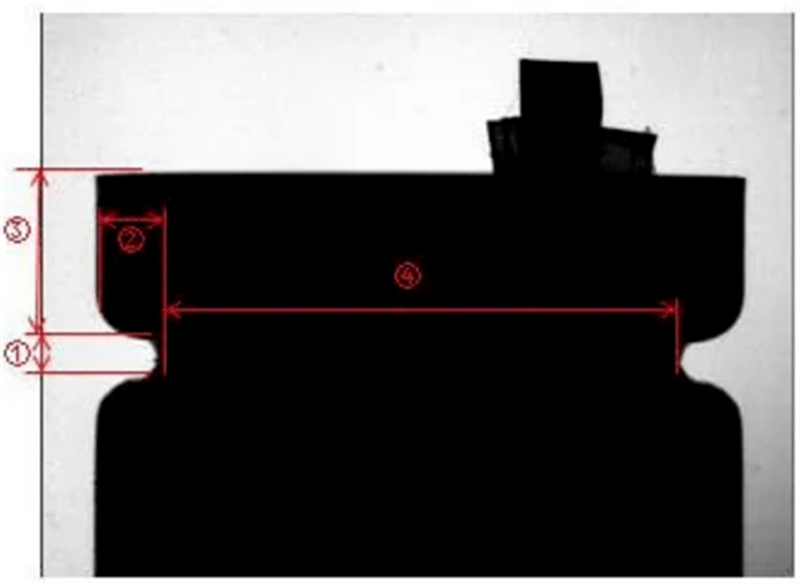

Roll groove size inspection:

Detection result:Intsoft Intelligent Vision System Measuring Dimensions and Dispensing Quality at the Same Time

Cap welding inspection

Product Measurement Schematic:

Detection Requirements:

1. Direction correction of battery tab

2. Cap post-weld quality inspection

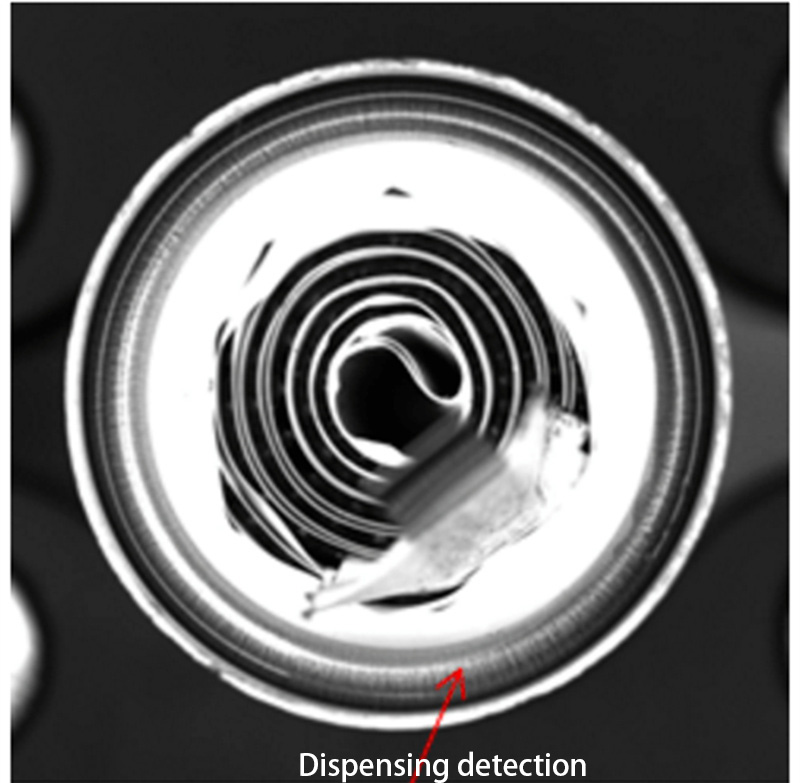

Detecting the top of the battery tap, detecting the angle of the battery tap:

Detection of pole piece and steel shell center point and calculation of distance value:

Detecting the height of the positive pole piece:

Inspection result: Intsoft vision inspection system can accurately calculate the offset angle of battery tap, judge the presence or absence of cap, and the deviation of cap welding.

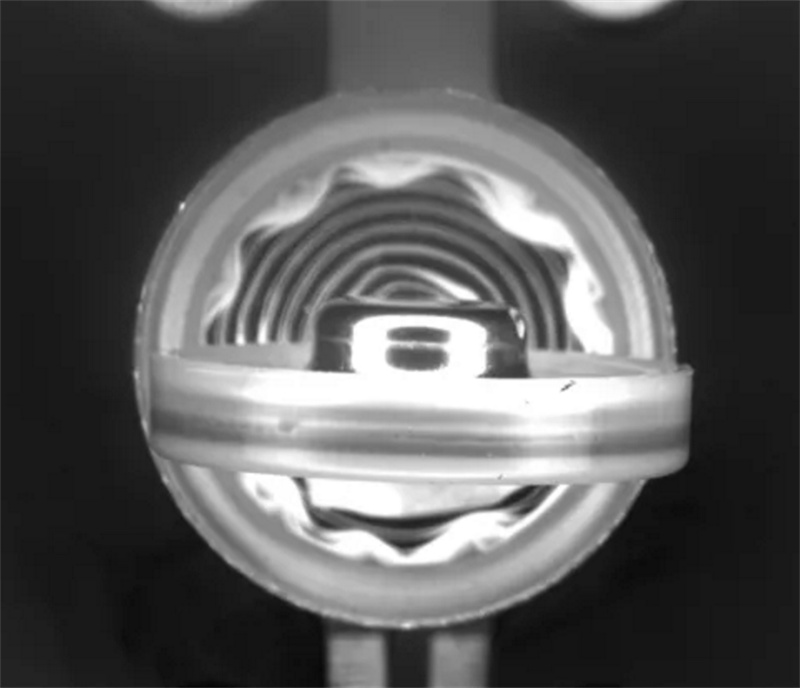

Cap angle correction

Detection requirements: Inspect the cap, control the angle of motor rotation

Inspection result: The rotation angle and direction of the cap are determined by finding the characteristic points on the cap, and the detection accuracy is about 0.04mm.

Cap placement of positive and negative detection

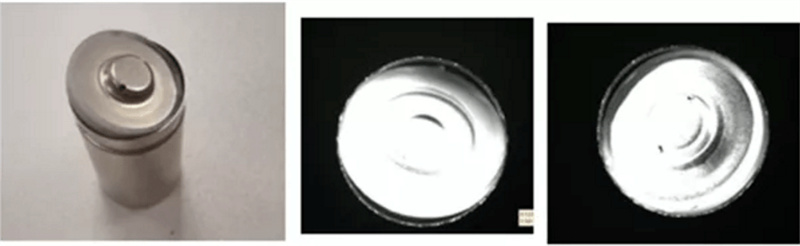

Detected cap original image:

Detection requirement:

1. Cap state:positive-OK, negative-NG, tilt-NG

2. Battery diameter: 16.3mm, battery center distance: 50mm

The original image of the reversed state and the lighting effect image:

The original image of the tilted state and the lighting effect image:

Detected result:It can meet the above inspection requirements with an inspection accuracy of about 0.052mm.

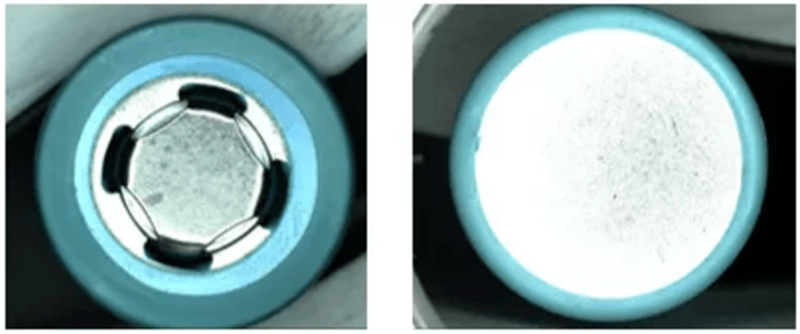

Battery end face inspection

Inspection Requirements.

1. Positive end of battery terminal casing quality inspection.

2. Battery negative terminal casing quality inspection.

Detection results:

- It can detect whether there are gaskets on the positive pole, whether there are defects on the casing, and whether there are pits and scratches on the battery end face.

- detect the quality of the casing on the negative pole and whether there are pits and scratches on the battery end face.

QR code detection

Detection requirements: Detecting the quality of QR code printing on batteries.

Detection result: Stable detection of skewed, defective printed QR codes on batteries.