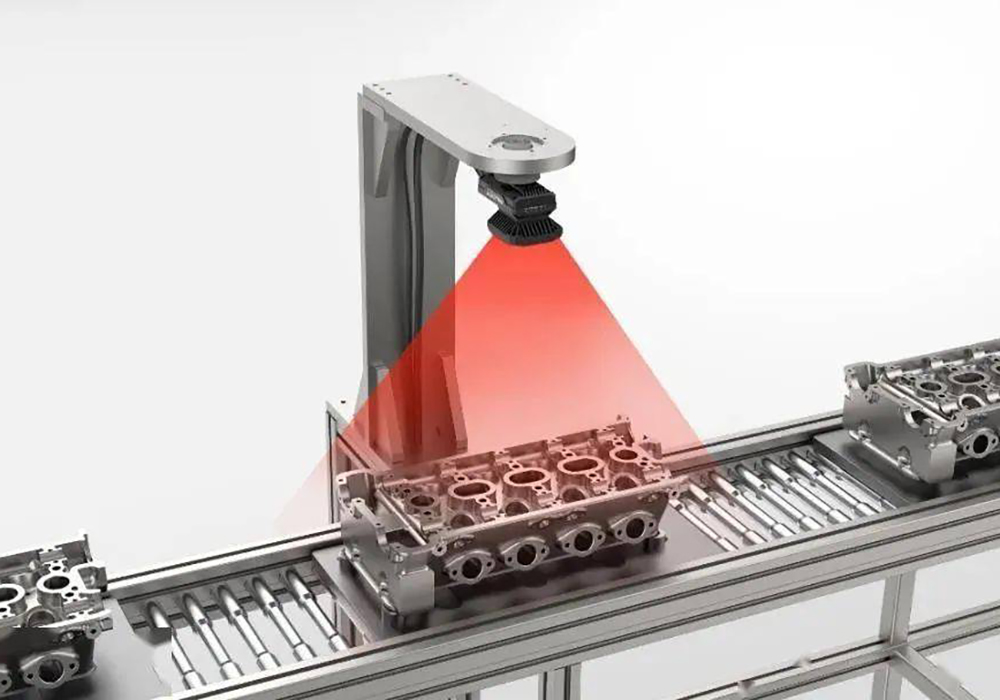

Achieving both quality and efficiency is paramount for manufacturers to keep pace with the evolving automotive industry. Engine block inspection is a critical area in which sophisticated technologies contribute significantly to quality without compromising production volumes. Machine vision systems are driving this revolution and helping automakers easily verify the integrity and uniformity of their engines’ vital parts: now more details on machine vision inspection of engine blocks. At the core of an automobile’s powertrain are engine blocks that contain cylinders and crankshaft, among other important parts. Quality assurance and precision engineering for engine blocks are as vital as they come, as any defects could lead to performance issues – and safety concerns plus costly recalls. Typically, inspection of engine blocks involves manual visual checks by trained technicians, which means that quality control can be compromised with this labor-intensive approach, as it is exposed to human error and inconsistency.

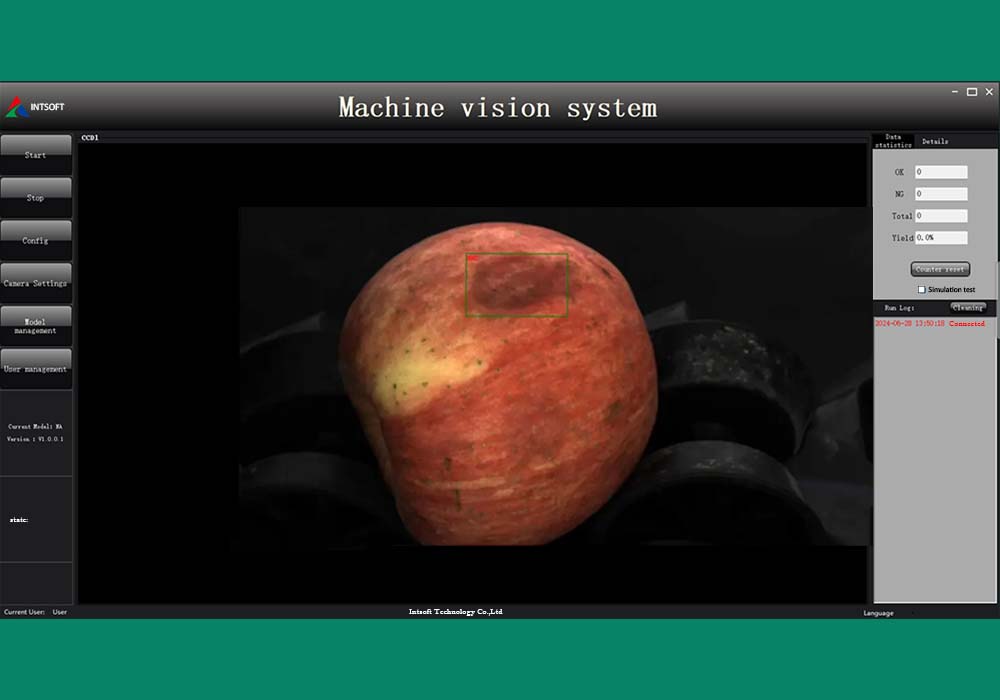

Introducing machine vision technology. Automakers use sophisticated computer vision algorithms, and high-speed imaging in the automation of engine block inspection , leading to a new era of unheralded quality control. A new technology in the field of engine block manufacturing is presented in the form of machine vision inspection systems, as quoted by John Doe, senior production engineer at ABC Automotive. “The extraordinary systems are able to detect any kind of anomaly and deficiency in no time without human assistance,” he says with a slight smile playing on his lips. “They can detect defects and deviations that would be almost impossible for the human eye to identify, all while operating at lightning-fast speeds.” Some factors that make machine vision-based inspection of engine blocks possible: An all-encompassing assessment: A machine vision system has the ability to scrutinize various features of an engine block that include dimensions, surface finish, casting quality and critical features without fail. This comprehensive strategy ensures that every component meets high quality requirements.

Consistent and Reliable Inspection: The use of machine vision systems makes inspection consistent and trustworthy because it is free from the subjectivity that comes with manual inspections; it provides unbiased results, eliminating any chance of human error so that each and every engine block can be viewed through uniform — high — standards. Increased throughput: Manufacturers will be able to perform automated machine vision inspections faster than manual due to increased speeds without compromising quality, allowing them to increase production volumes. Machine vision systems generate data that can provide manufacturing process intelligence: it can be used by automakers to make their operations more optimal — identifying trends — implement predictive maintenance strategies and ultimately improve the effectiveness and quality of their work.

As the automotive industry continues to evolve, the importance of engine block quality and consistency will only grow. By embracing machine vision technology, automakers can drive quality, efficiency, and innovation, solidifying their position in an increasingly competitive market. The future of engine block manufacturing is here, and it’s powered by the precision and accuracy of machine vision inspection.