Heat sinks are crucial in electronic devices as they help dissipate heat generated by various electronic components such as processors, power supplies, and other high-power devices.

By integrating machine vision-based heat sink detection into the production process, electronics manufacturers can improve the reliability, performance, and safety of their products, while also enhancing their overall quality control and manufacturing efficiency.

Intsoft Technology has documented the process of detecting heat sink defects as follows.

Detection content and requirements

Size of detected item: Length 42.55mm / Width 18.5mm / High 11.5mm, surface detection, dimension measurement

Detection content:

1. Side positive light detection size

2. Side positive light inspection appearance

3. Top positive light detection size

4. Top positive light inspection appearance

5. Bottom positive light inspection appearance

6. Bottom positive light inspection appearance

7. Side positive light detection size

Note: The above inspection items must be clearly visible under the image to be detected.

Inspection efficiency: 50-100 pieces per minute (according to sample feeding speed).

Segmentation: Subdivision of inspection steps according to inspection content.

Equipment composition and main institutions

Overall Composition Size:900*800*1850 mm

Model:INTSOFT_302C

1. INTSOFT Visual Inspection Software

2. Industrial computer

3. 19 inch Display

4. Industrial camera: 6 sets, respectively, the top of the detection pins crooked, oxidation, left side of missing parts, right side of missing parts

Side backlight detection pins crooked, bottom detection oxidation, lack of pins, bottom detection of foreign matter between pins.

5. Industrial lens: 5sets of FA industrial camera, 2 set of telecentric lenses

6. Professional glass disk

7. Solenoid valve

8. Reducer

9. Vibration machine

10. Feeding equipment (vibration disc, electro-vibrating feeder, controller).

Detection process

Side detection:

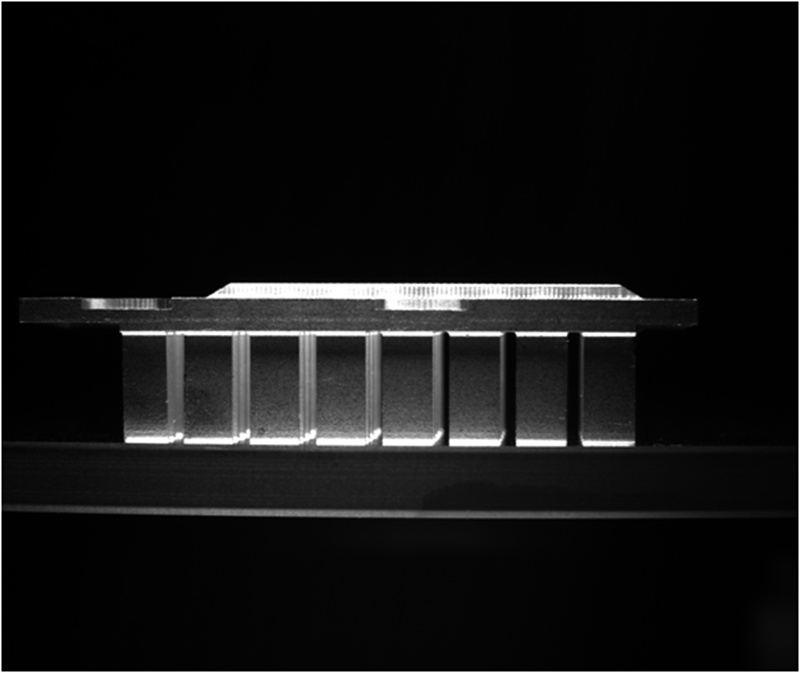

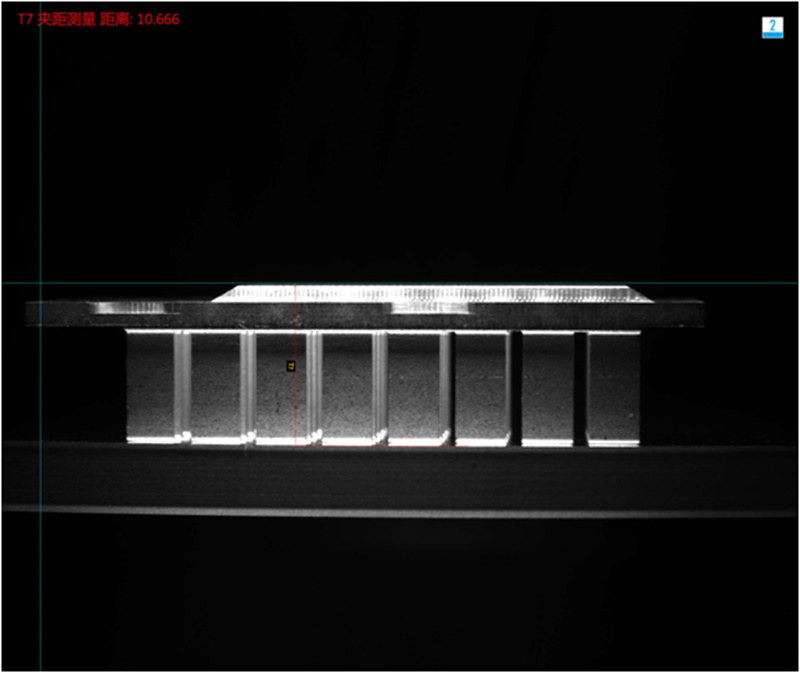

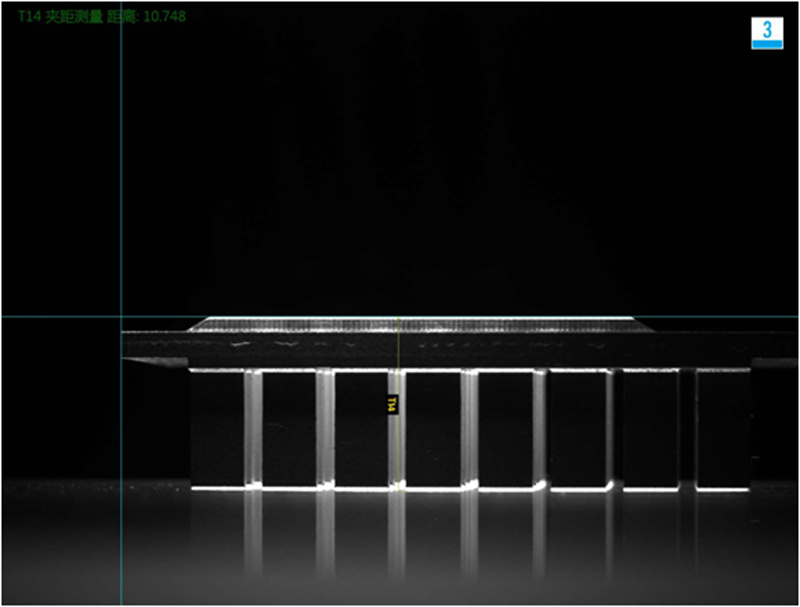

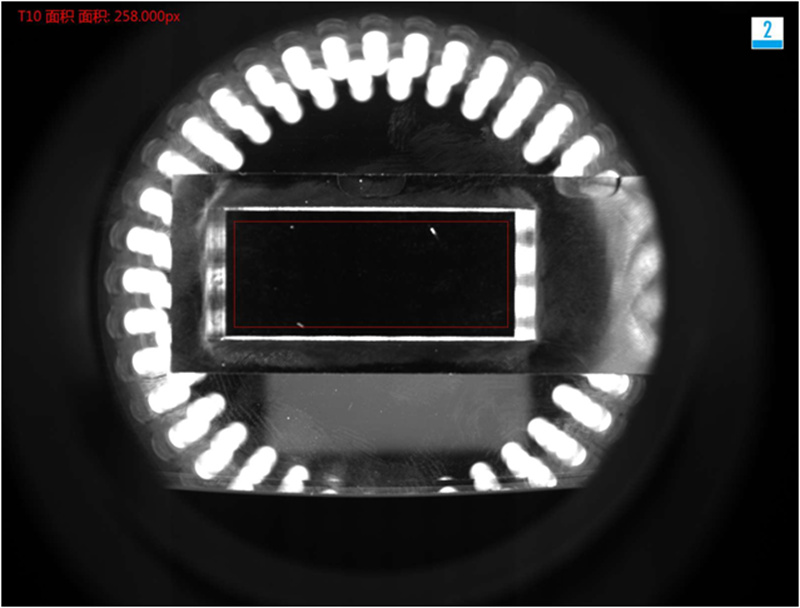

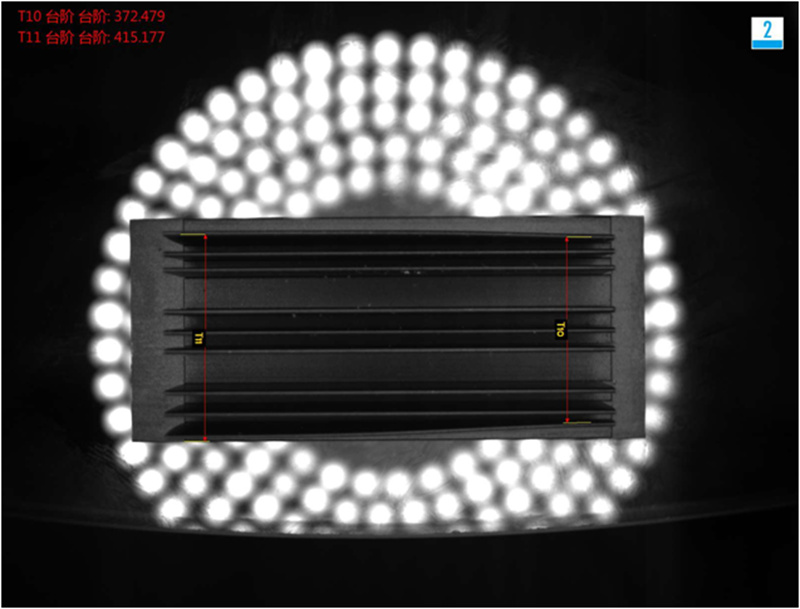

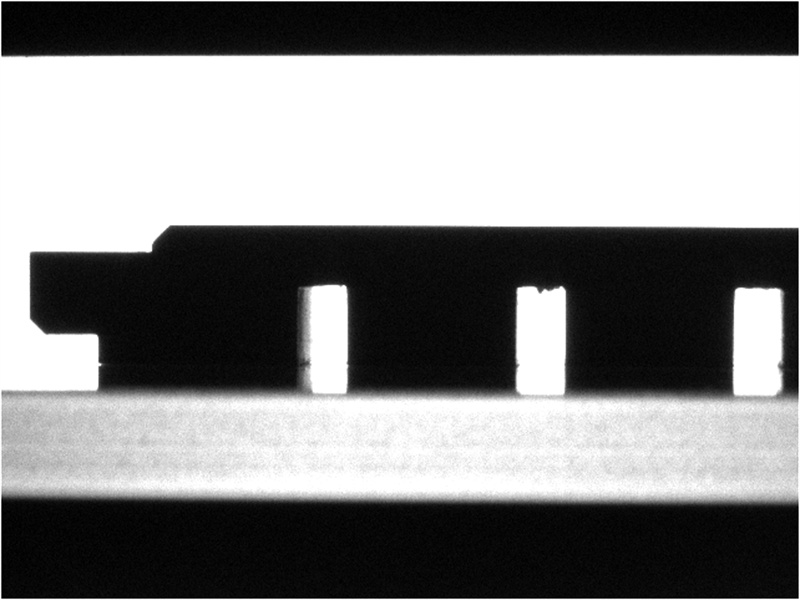

Side detection original image:

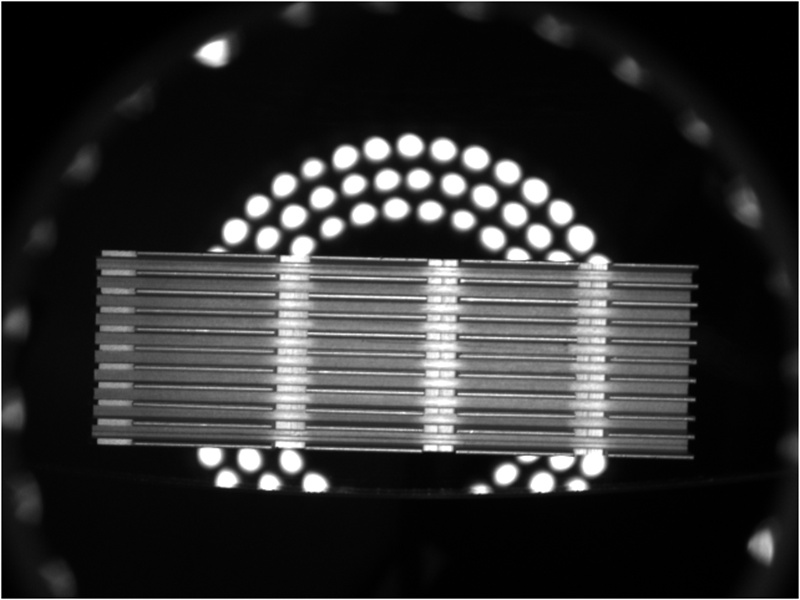

Side detection good product analysis image: OK —

Side detection defective product analysis image: NG —

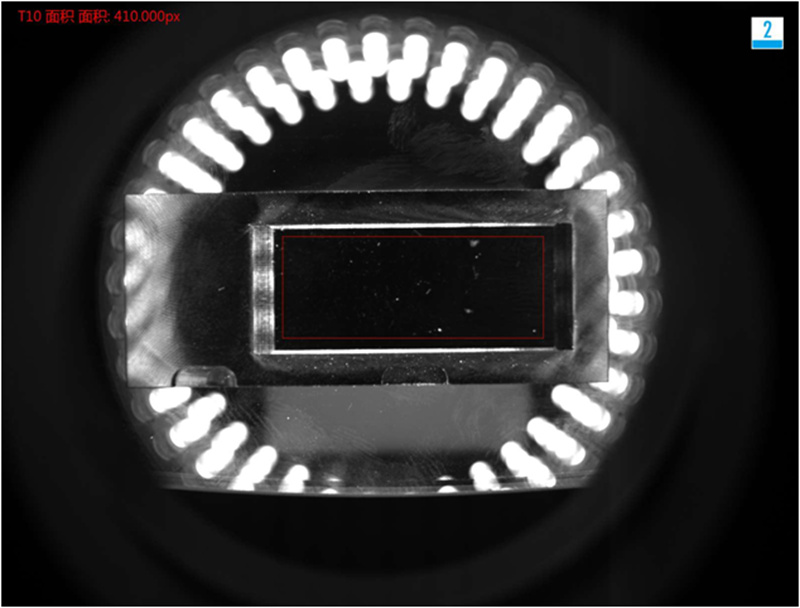

Side detection original image:

Side detection good product analysis image: OK —

Side detection defective product analysis image: NG —

Top detection

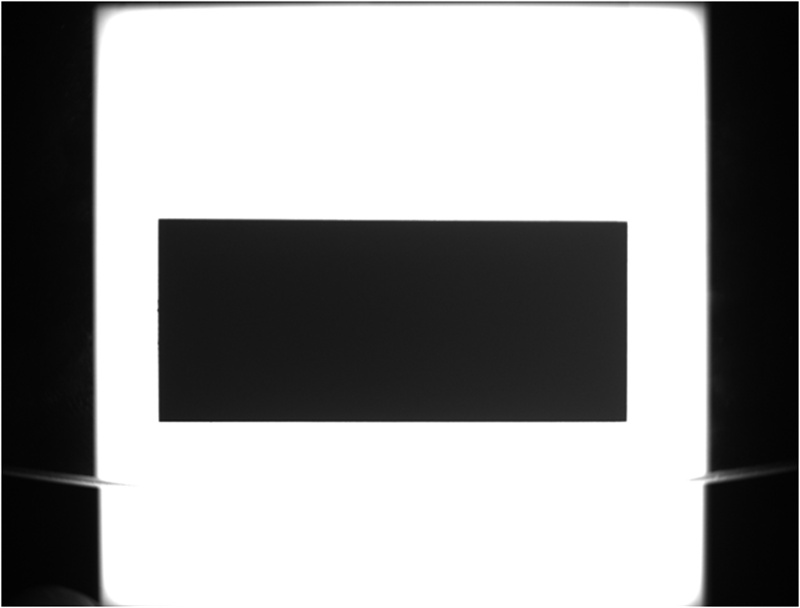

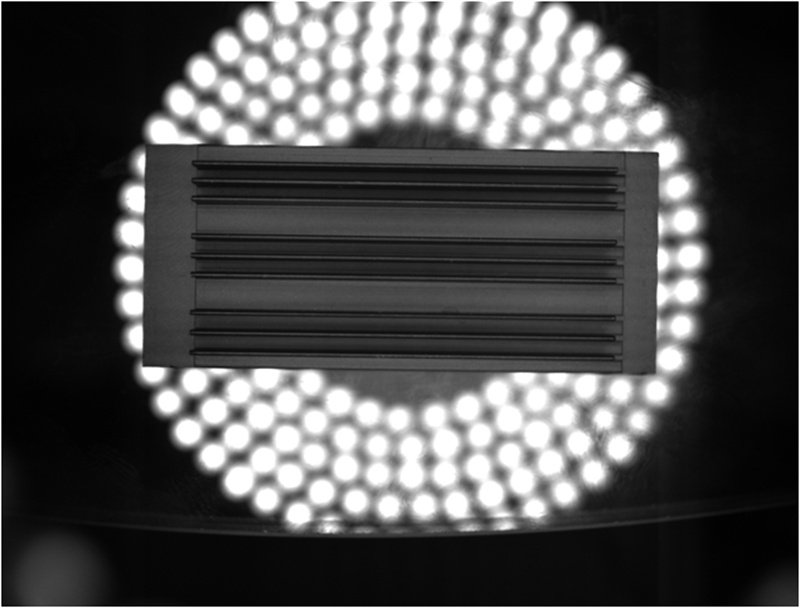

Top detection original image:

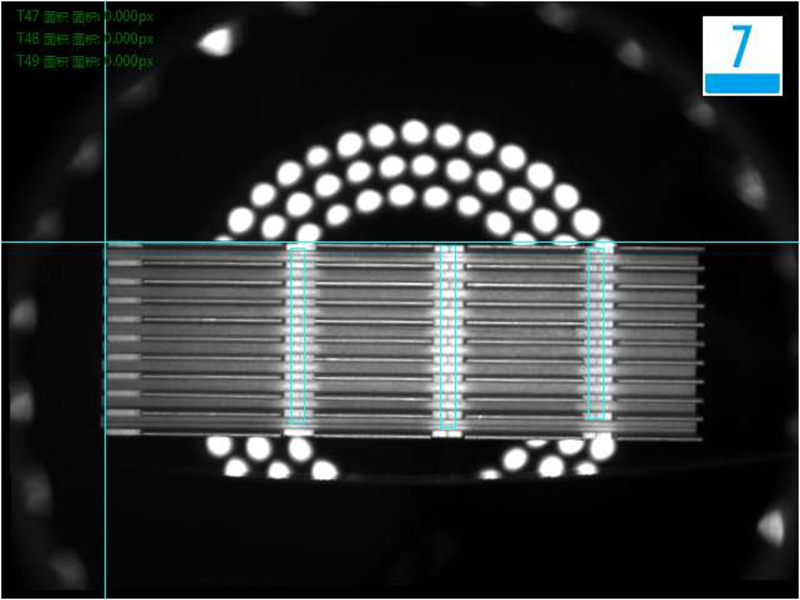

Top detection good product analysis image: OK —

Top detection original image:

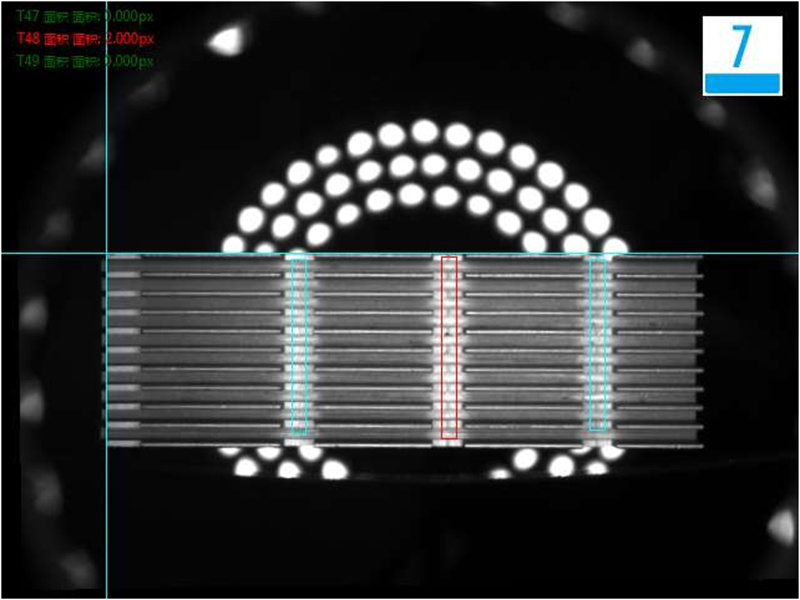

Top detection defective product analysis image: NG Cause of defect: Stain, scratch —

Top detection defective product analysis image: NG Cause of defect: Stain, scratch —

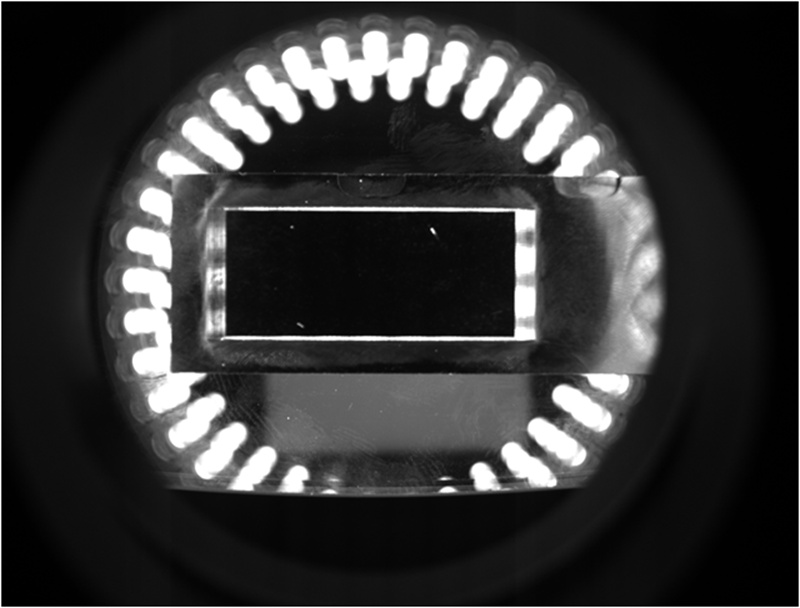

Bottom detection

Bottom detection original image:

Bottom detection good product analysis image: OK —

Bottom detection defective product analysis image: NG Cause of defect: Tilt —

Bottom detection original image:

Bottom detection good product analysis image: OK —

Bottom detection defective product analysis image: NG Cause of defect: Edge burrs —

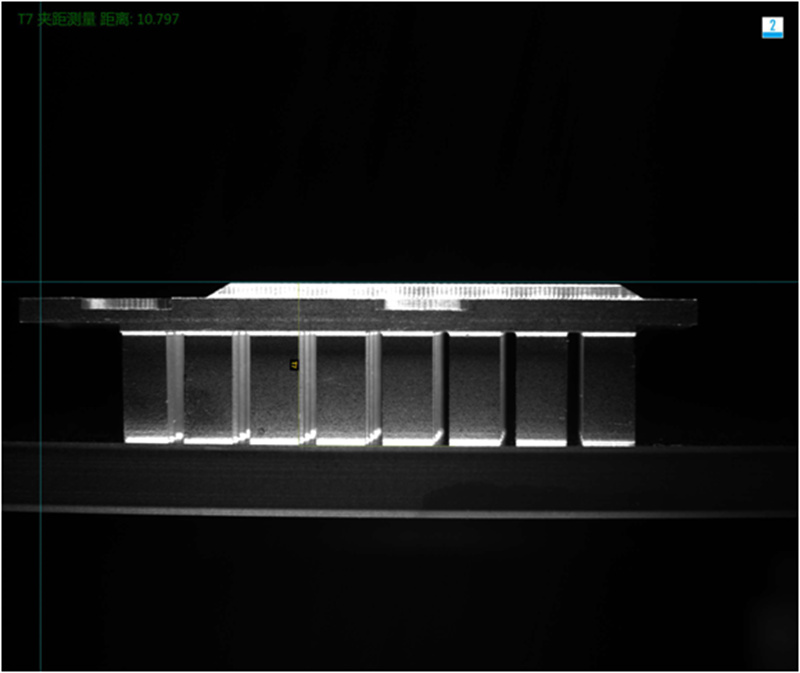

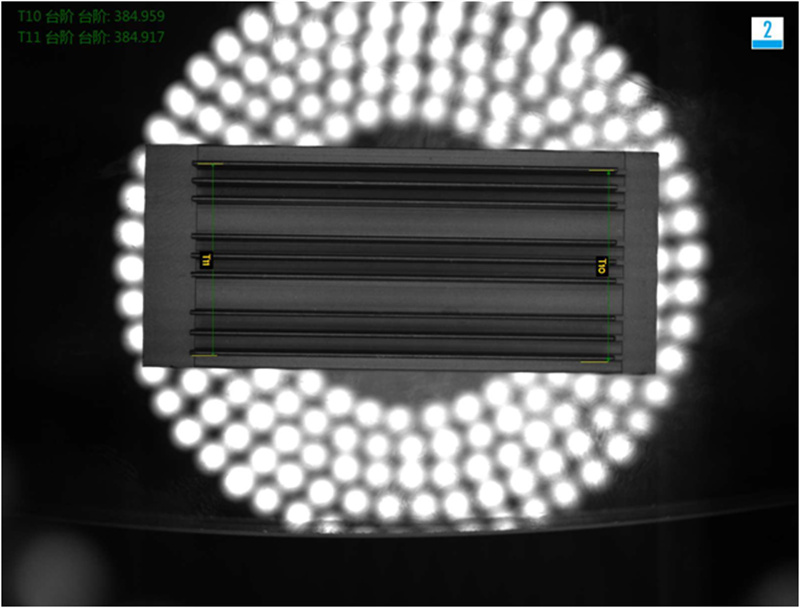

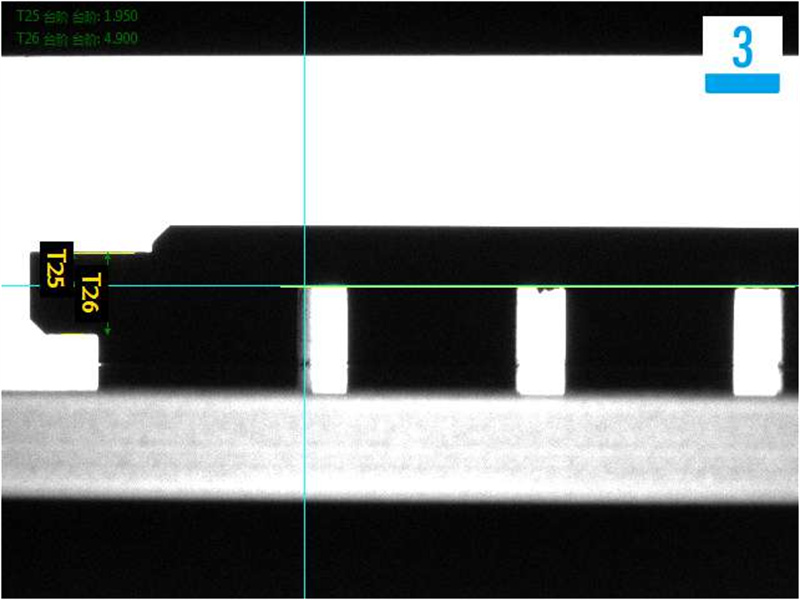

Size detection

Side detection original image:

Side detection good product analysis image: OK —

System installation requirements

Equipment placed in the inspection space: In the assembly line side of the installation of Intsoft vision inspection system alone, you need to ensure that there is enough space to install the equipment.

Ambient temperature: 0-50 degrees Celsius;

Air humidity: 90% RH or less;

Electronic interference: Provide a place with less electronic interference for the equipment.

Power supply: AC 220V, 50Hz, Power consumption <1KVA, Air pressure 0.35 ~ 0.7MPa

The above is the USB socket machine vision inspection program. If your industrial production line needs vision detection technology, do not hesitate to talk to Intsoft Technology, we will give you the most professional advice.