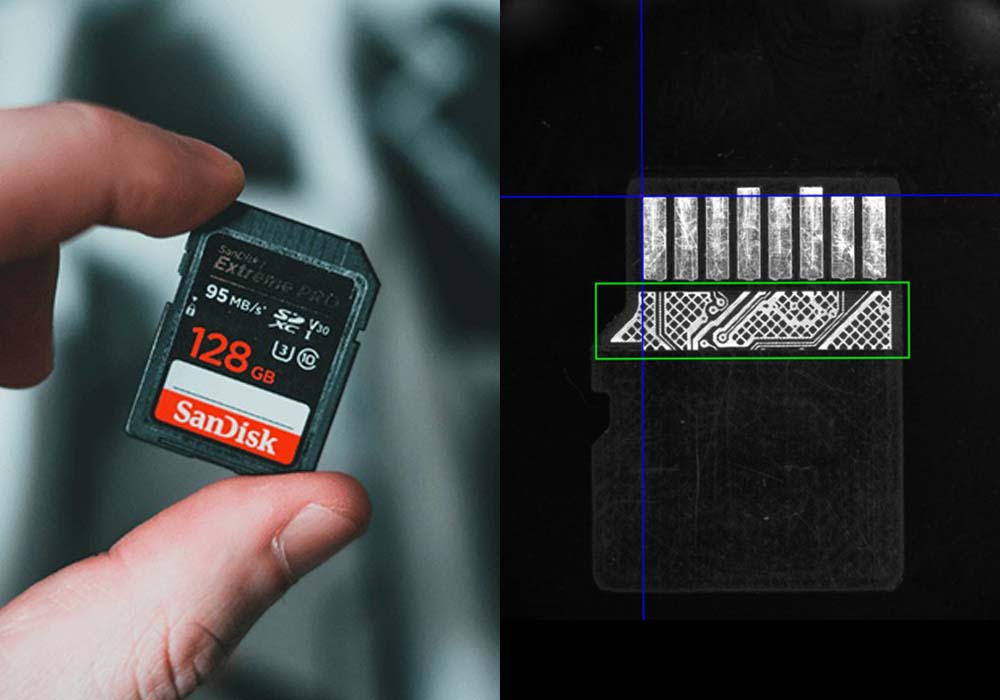

Pins are conductive metal leads or terminals that extend from electronic components, allowing them to be connected to a circuit board or other electronic device. Pins act as the interface between the component and the external circuitry, allowing the flow of electrical signals, power, and ground connections.

Effective pin defect detection is critical to ensuring the quality and reliability of electronic products.

The following is an example of Intsoft Technology’s PIN defect detection.

Detection content and requirements:

Surface detection of products with maximum dimensions of L14mm*W14mm*H6mm.

1. Bottom positive light surface detection

2. Top positive light surface detection

Note: The above inspection items must be clearly visible under the image to be detected.

Inspection efficiency: 200-250 pieces per minute (according to sample feeding speed).

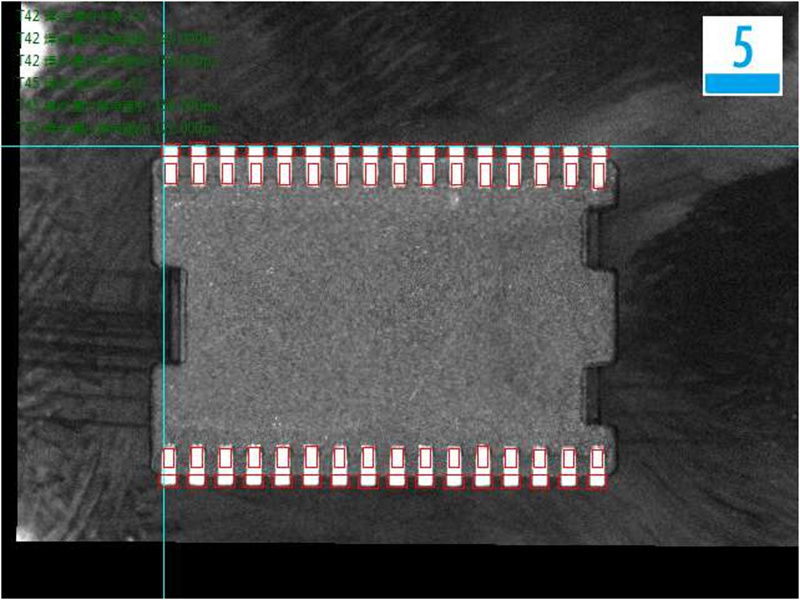

Segmentation: Subdivision of inspection steps according to inspection content.

Equipment composition and main institutions

Overall Composition Size:900*800*1850 mm

Model:INTSOFT_302C

1. INTSOFT Visual Inspection Software

2. Industrial computer

3. 19 inch Display

4. Industrial camera: 2sets, bottom positive light: 1set, top positive light: 1 set

5. Industrial lens: 2sets, FA industrial camera: 2.

6. Professional glass disk

7. Solenoid valve

8. Reducer

9. Vibration machine

Overall photo of the machine

Bottom detection

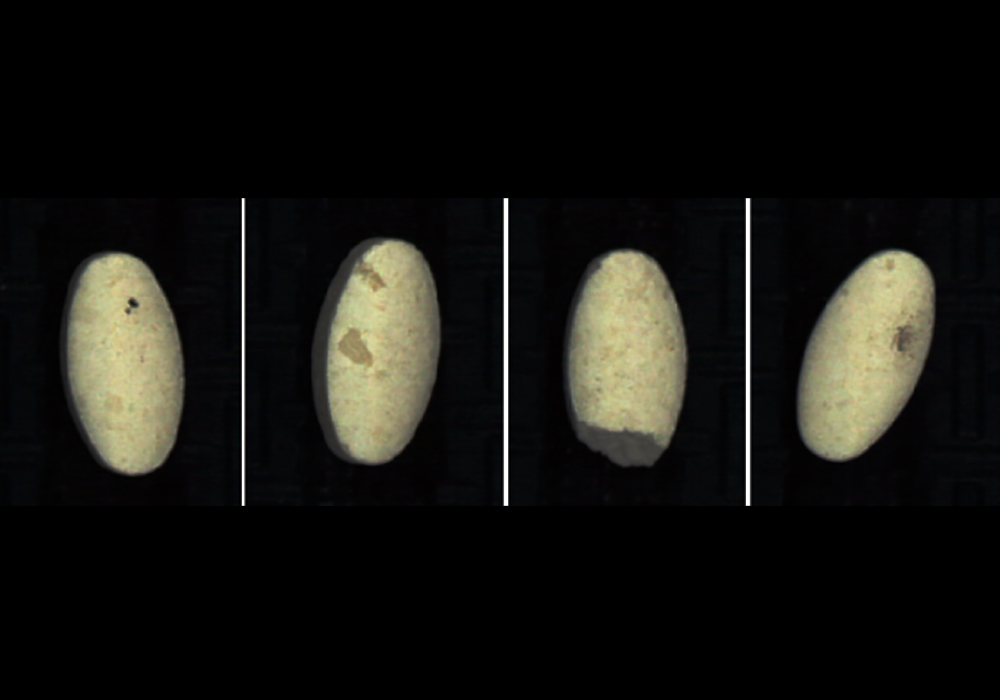

Bottom detection original image:

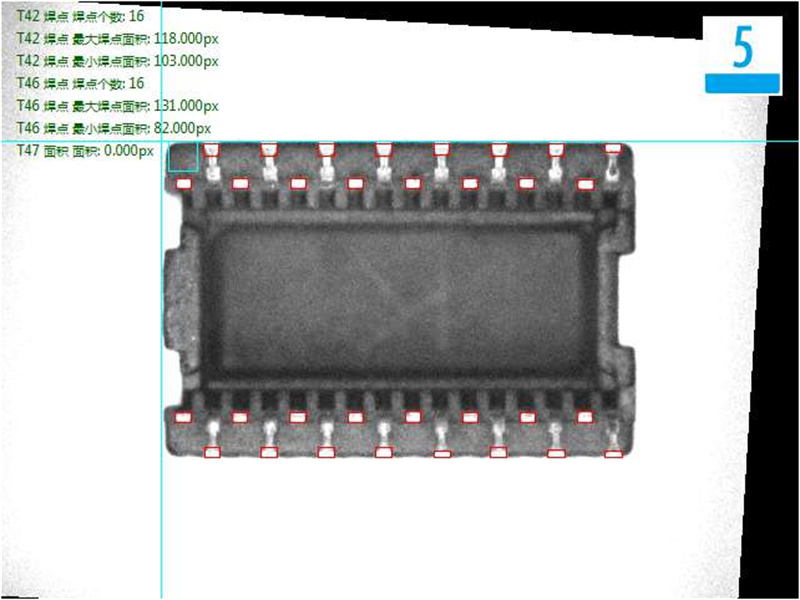

Bottom Positive Light detection good product analysis image: OK

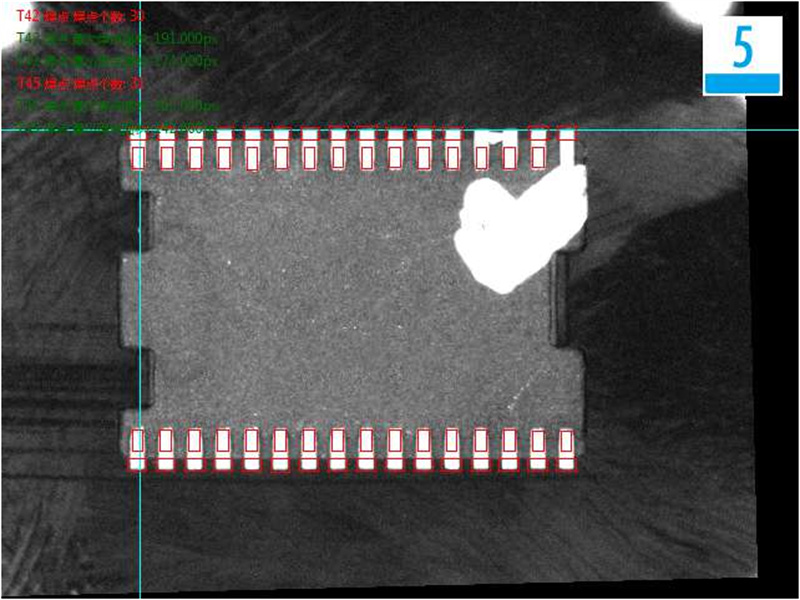

Bottom Positive Light detection defective product analysis image: NG Cause of defect: Excess solder paste on the reverse side

Bottom Positive Light detection defective product analysis image: NG Cause of defect: Pins reverse

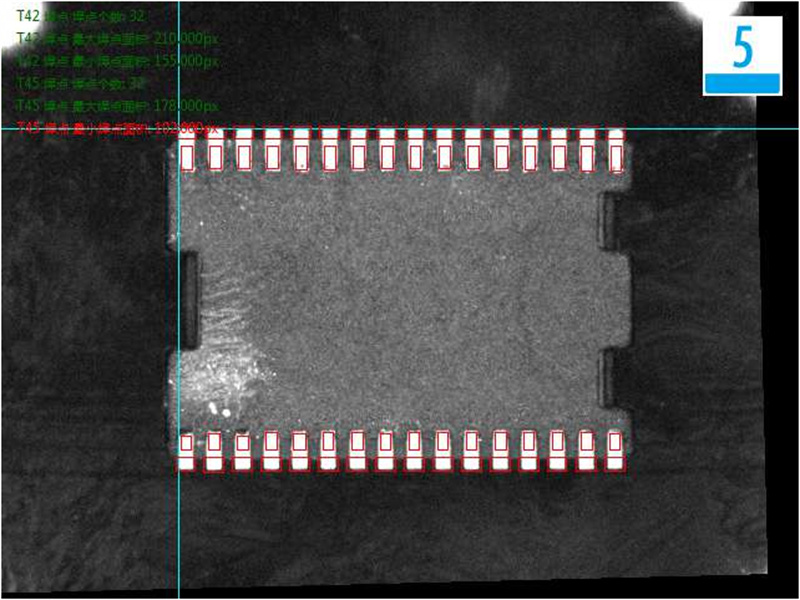

Bottom Positive Light detection defective product analysis image: NG Cause of defect: Edge burr

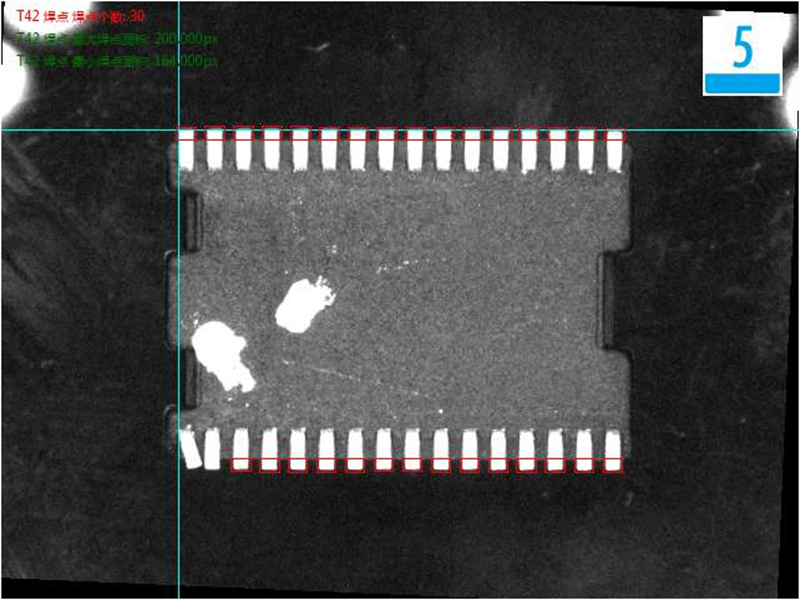

Bottom Positive Light detection defective product analysis image: NG Cause of defect: Slag

Top detection

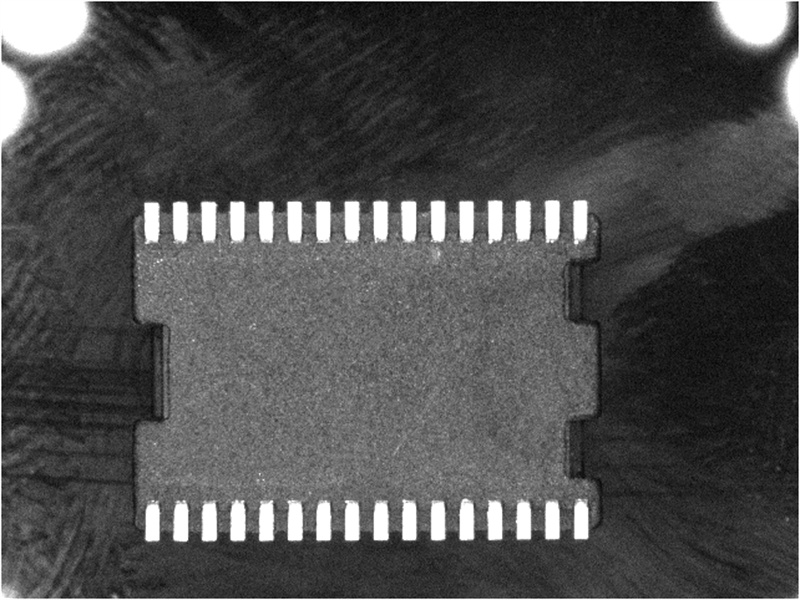

Top detection original image:

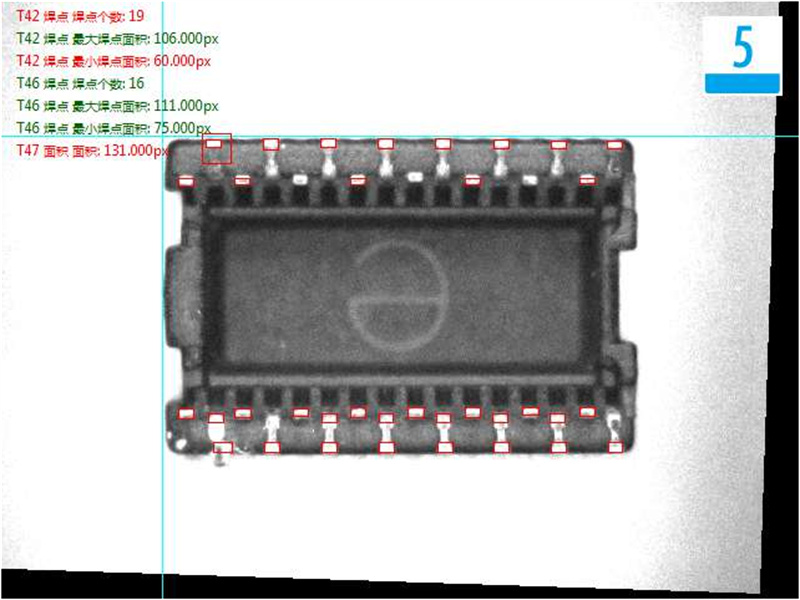

Top positive Light detection good product analysis image: OK

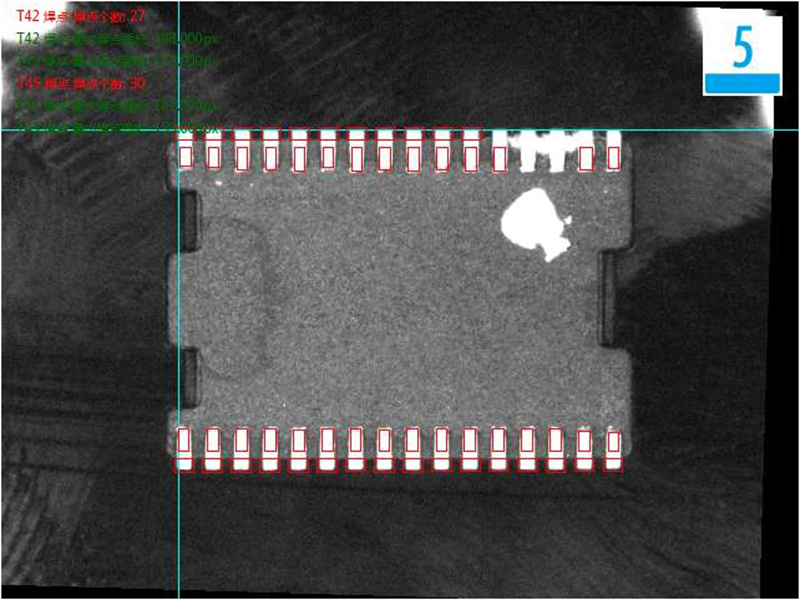

Top positive Light detection defective product analysis image: NG Cause of defect: Front side pin tilt

System installation requirements

Equipment placed in the inspection space: In the assembly line side of the installation of Intsoft vision inspection system alone, you need to ensure that there is enough space to install the equipment.

Ambient temperature: 0-50 degrees Celsius;

Air humidity: 90% RH or less;

Electronic interference: Provide a place with less electronic interference for the equipment.

Power supply: AC 220V, 50Hz, power consumption <1KVA

The above pin detection cases are from Intsoft Technology internal data. For more information, please contact intsoft technology.