Memory cards are ubiquitous components found in a wide range of electronic devices, from smartphones to digital cameras. Ensuring the consistent quality and appearance of these cards is crucial to maintaining product reliability and customer satisfaction. This case study record parts of the automated machine vision inspection process for memory card appearances.

Inspection items:

1. Metal part of memory card size measurement.

2. Metal part of memory card surface defect inspection

Inspection structure:

| No. | Item name | Model | Amount |

| 1 | software | Intsoft Tech Customized | 1 |

| 2 | Industrial computer | Intsoft Tech Customized | 1 |

| 3 | Monitor | PHILIPS22” LCD monitor | 1 |

| 4 | Industrial camera | Sony industrial camera | 1 |

| 5 | Camera adjustment module | Intsoft Tech Customized | 1 |

| 6 | Industrial lens | Telecentric HD optical industrial lens | 1 |

| 7 | Ring light source | Custom optical adaptive light source | 1 |

| 8 | Control system | Intsoft Tech Customized | 1 |

| 9 | Servo motor | 1 | |

| 10 | Reducer | Intsoft Tech Customized | 1 |

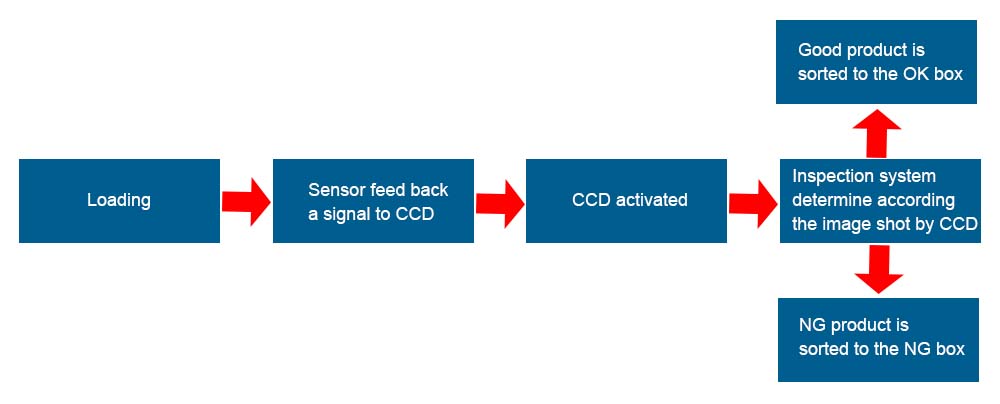

Inspection procedure:

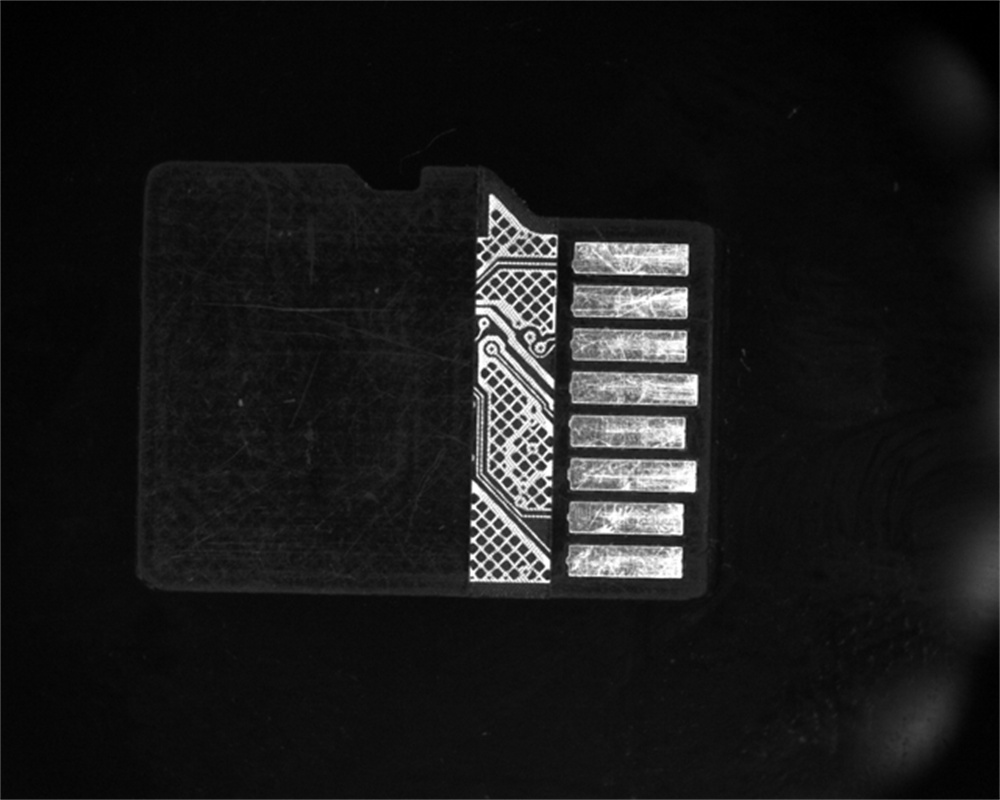

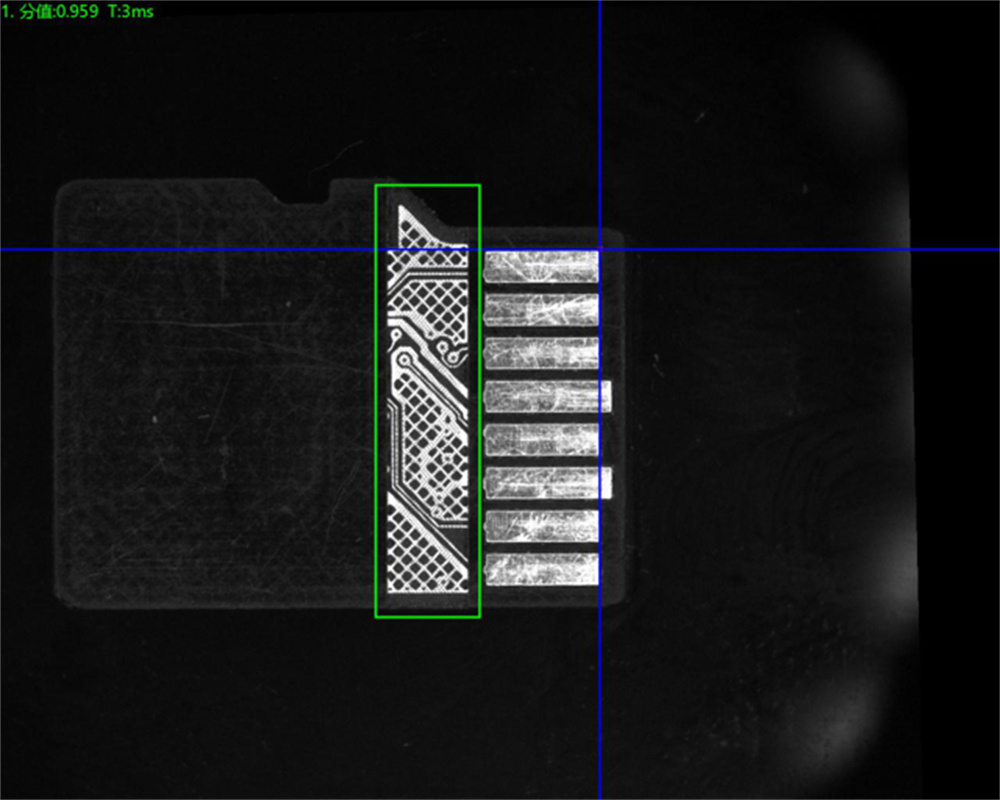

Inspection image

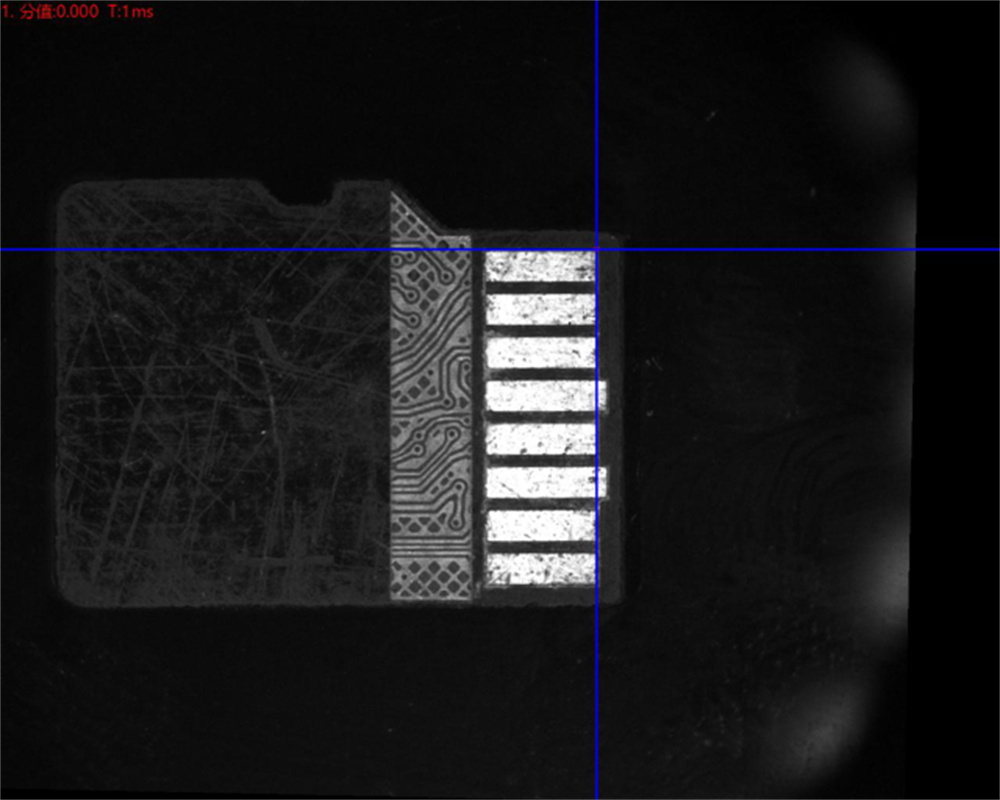

Top view positive light inspection original image:

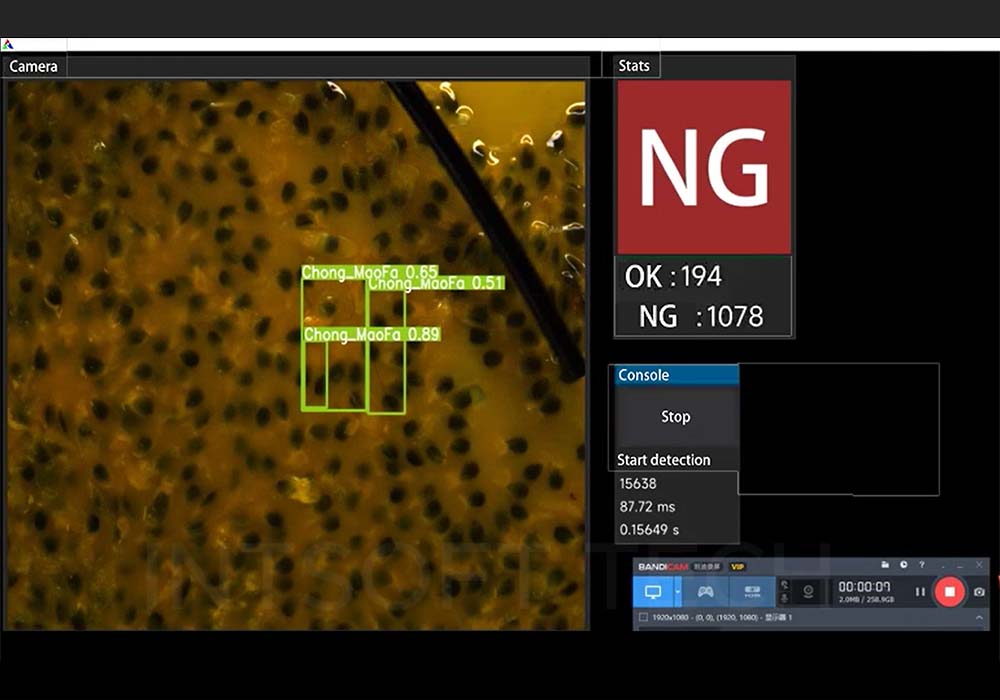

Top view positive light inspection good product analysis image:

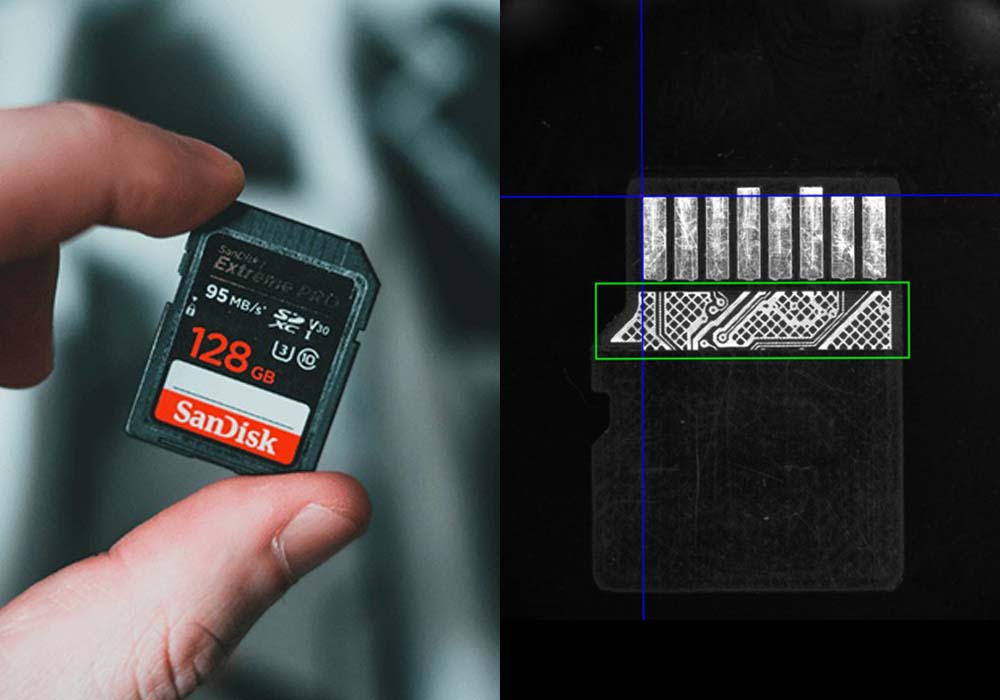

Top view positive light inspection defective product analysis image: Cause: Incorrect length of metal strip —