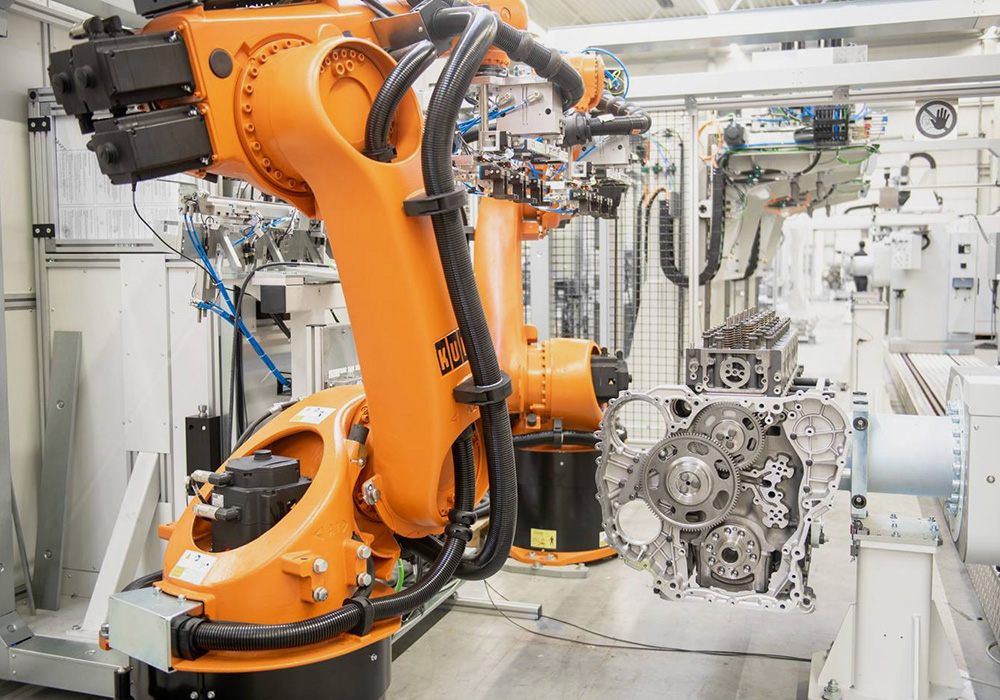

With the development of industry, defect detection is a very important application in industry. Due to the variety of defects, traditional machine vision algorithms are difficult to achieve complete modeling and migration of defect features, with little reusability, which will waste a lot of labor costs. While deep learning has achieved very good results in feature extraction and localization, more and more people are beginning to introduce deep learning algorithms into the field of defect detection.

The following will introduce the application of deep learning algorithms in the field of Intsoft Technology defect detection.

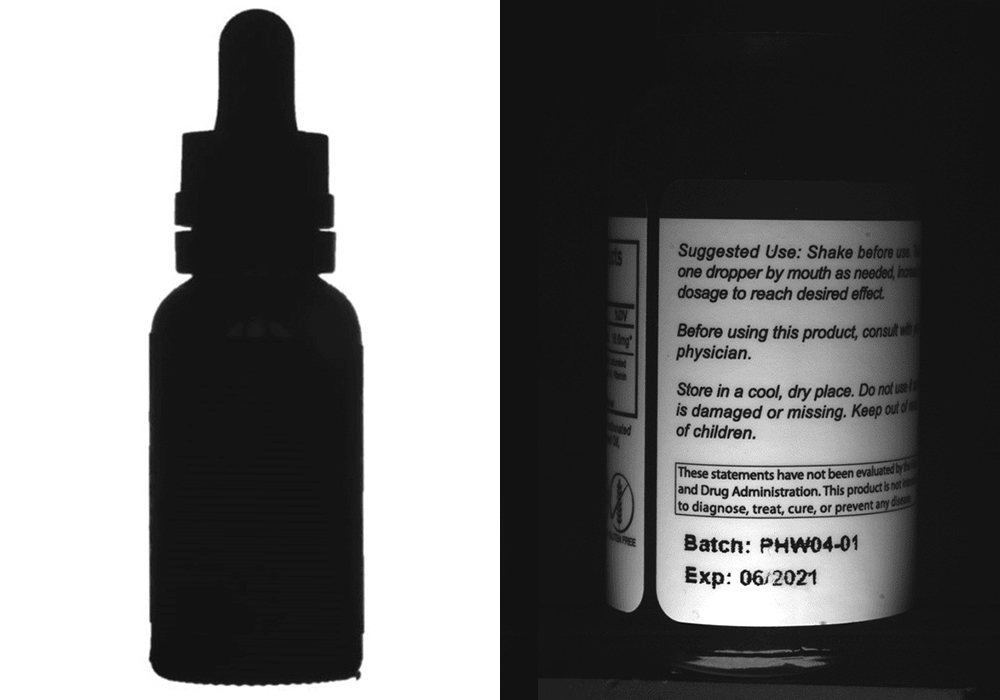

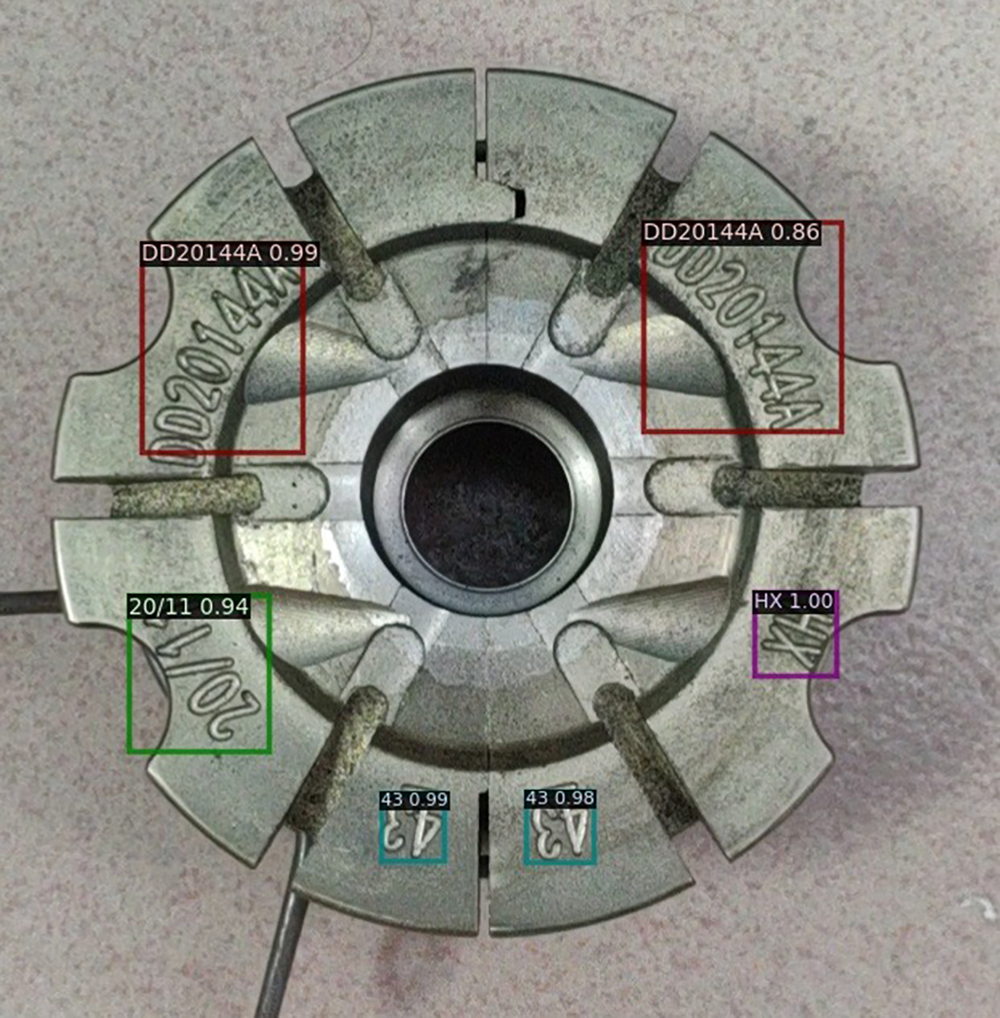

Product character recognition:

Identify the characters on the product according to the customer’s needs and store them in the designated storage space.

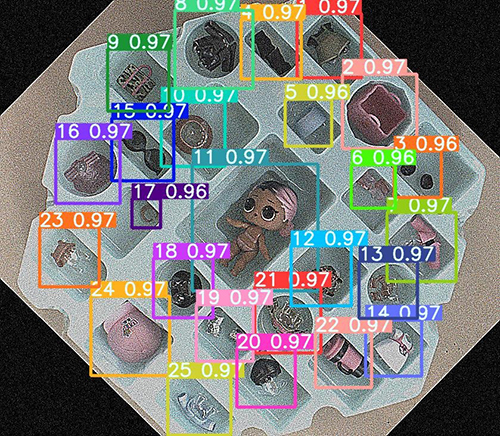

Detection of accessories in Blister tray

According to customer demand, detection of accessories on the blister tray, whether the accessories are too many or accessories installed in reverse, installed wrong and so on.

There are many similar industrial needs, the human eye can recognize things, AI through deep learning can also be identified. In today’s expensive labor costs and huge management costs, the good use of machine vision can play an unexpected effect, the cost can be reduced, and the yield rate is also improved.