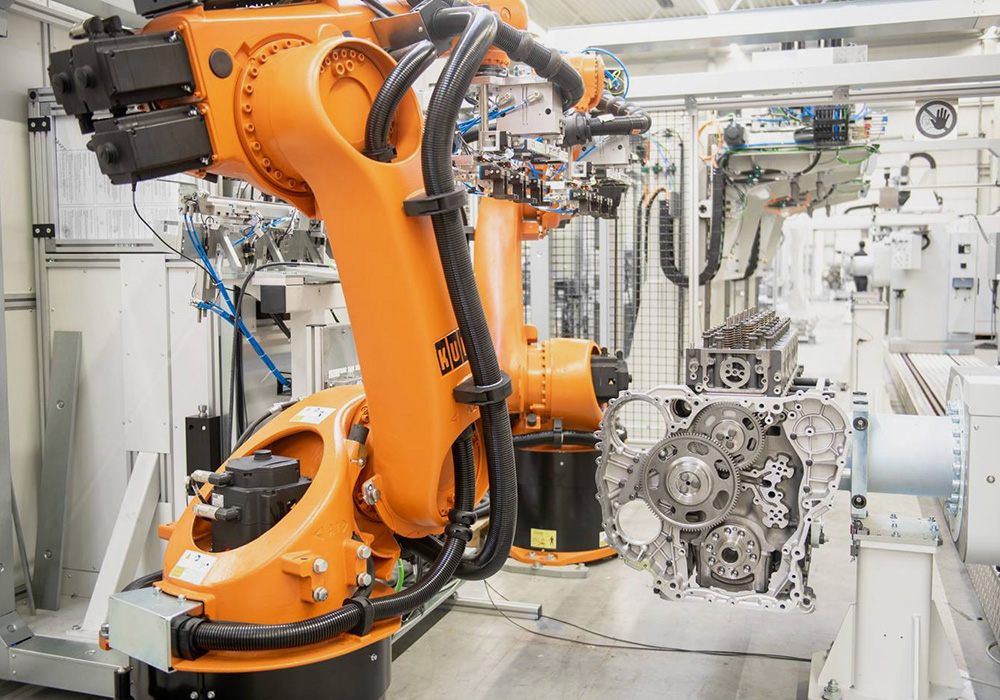

In the dynamic landscape of the automotive industry, precision and efficiency are critical to achieving a competitive advantage. INTSOFT TECH has launched an advanced Machine Vision System designed to seamlessly integrate with KUKA robotic arm, facilitating the assembly of automotive parts. This state-of-the-art solution redefines traditional assembly processes, empowering robots to perform complex tasks with exceptional speed and accuracy.

Need for innovative assembly solutions

Challenges in Automotive Assembly

The assembly of automotive components involves complex tasks that require precise alignment and secure fastening. Traditional manual assembly methods can lead to inconsistencies and longer production times, underscoring the need for automated solutions that enhance workflow efficiency and reduce costs.

Key Features of INTSOFT TECH’s Machine Vision System

1. High-Resolution Imaging

The system uses high resolution cameras to capture detailed images of car parts during the assembly process. This capability ensures accurate identification and positioning of components, leading to precise assembly.

2. Advanced Image Processing

Using sophisticated image processing algorithms, the machine vision system analyzes captured images in real time. This feature allows for the immediate detection of variations in part orientation, allowing the robotic arm to make quick adjustments as needed.

3. Dynamic Path Optimization

The system intelligently calculates the most efficient paths for the KUKA robotic arm, minimizing unnecessary movements and improving overall assembly efficiency.

4. Real-time feedback mechanism

Continuous monitoring throughout the assembly process provides real-time feedback, allowing immediate corrections to ensure accurate and secure assembly of each part.

5. User-Friendly Interface

With an intuitive interface, the system simplifies the configuration and monitoring of assembly tasks, significantly reducing training time for operators.

Benefits of the Integrated System

1. Exceptional Precision

The integration of machine vision ensures that car parts are assembled with high accuracy, greatly reducing the risk of misalignment and defects.

2. Increased Efficiency

Automating the assembly process accelerates production rates, allowing the robotic arm to operate continuously, resulting in higher throughput and shorter cycle times.

3. Cost Savings

By minimizing errors and relying on manual labor, manufacturers can achieve substantial cost savings, making this investment in automation highly beneficial.

4. Enhanced Quality Control

Real-time monitoring facilitates the rapid identification and correction of assembly problems, ensuring that each vehicle meets stringent quality standards.

5. Manufacturing Flexibility

The system can be easily reprogrammed to accommodate different car models and assembly configurations, providing essential flexibility to adapt to changing production needs.