LED digital tubes are ubiquitous in our lives, such as electronic clocks in the display of time is a digital tube, calculators, multimeters and other displays are used in the digital tube.

In the LED digital tube production line, the traditional method of product quality control mainly relies on manual visualization to achieve, but due to the subjectivity of human eyes, it is difficult to accurately and stably control the quality of the product.

For this reason, a device that can quickly and effectively detect display defects is needed to replace the detection of subjective evaluation by the human eye.

Compared to the human eye, the machine vision system has high speed, high accuracy, repeatability, and long-term working stability. After applying machine vision inspection technology for optical inspection of digital tubes, the accuracy and speed of product quality control can be greatly improved.

The following mainly introduces machine vision based on the realization of digital tube character defects for rapid and accurate detection.

Detection object: plastic digital tube.

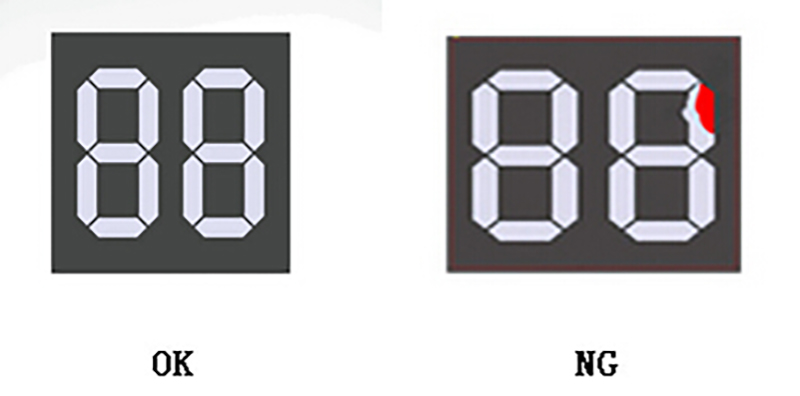

Detect defects: scratches, stains, character defects.

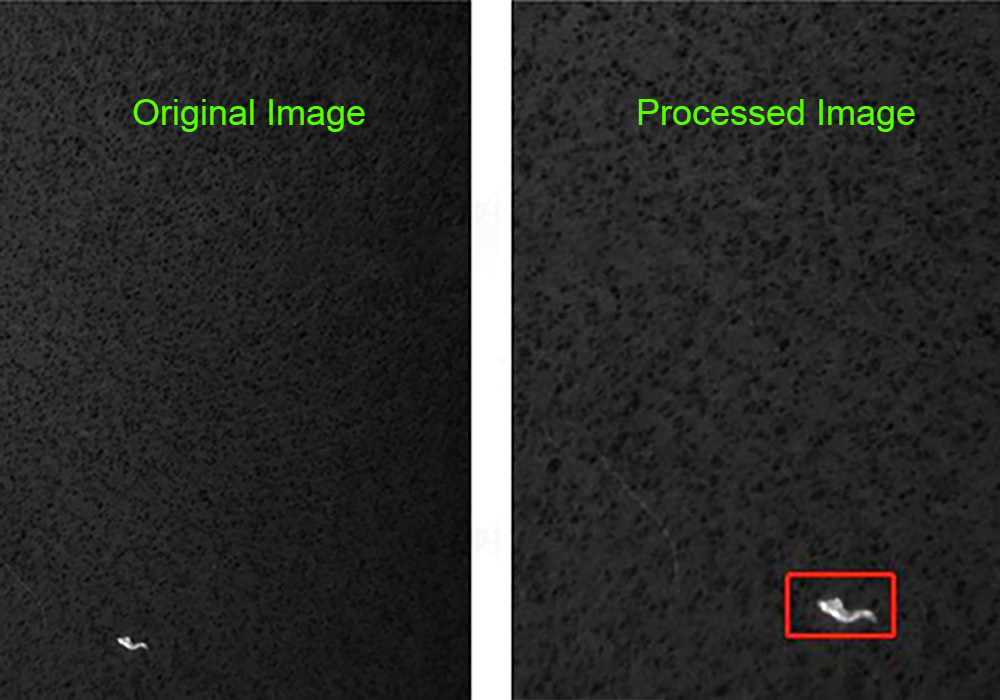

Detection effect image:

This inspection uses Intsoft Technology series of highresolution industrial cameras with megapixel industrial lenses and Intsoft machine vision image processing software to detect characters on the surface of the digital tube.

First of all, the industrial digital camera captures images, and then through image processing software on its image preprocessing, defect detection. When detecting defective workpieces, the system can also be based on the actual needs of the corresponding control signals.

Intsoft Technology machine vision defect detection system in the industrial assembly line to detect products, can be 99.97% accurate in a variety of high-speed continuous product production, real-time, accurate surface quality inspection, to improve production automation and ensure that quality control provides an effective solution. Intsoft Machine Vision Detection is now widely used in plastic digital tubes, LED digital tubes, instrument panels, keyboards, printing, flat panel displays, plastic film , and if you need to use machine vision inspection technology in your industrial production line, please contact us.