Electronic components are critical components in a wide range of products, from consumer electronics to industrial equipment. Ensuring the quality and reliability of these components is paramount, and automated visual inspection plays a vital role in the process. So, what equipment do companies need to use to ensure their quality when detecting electronic component products?

–Visual inspection equipment for electronic component products

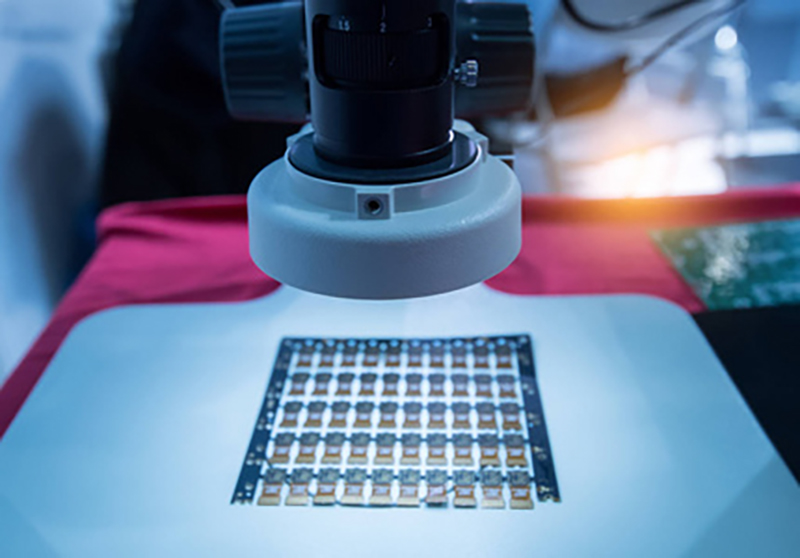

Due to the fact that electronic components are generally small, and the environmental requirements are more stringent, they can not be detected by manual mass inspection, only through customized machine vision inspection software and equipment.

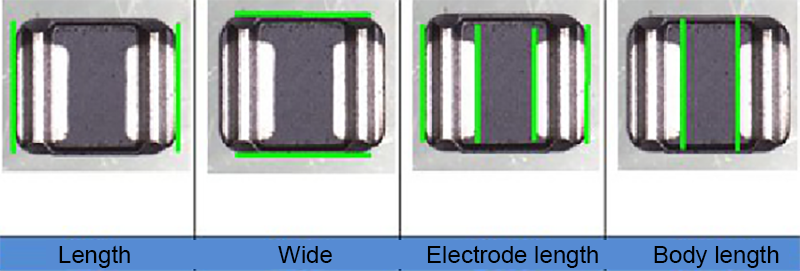

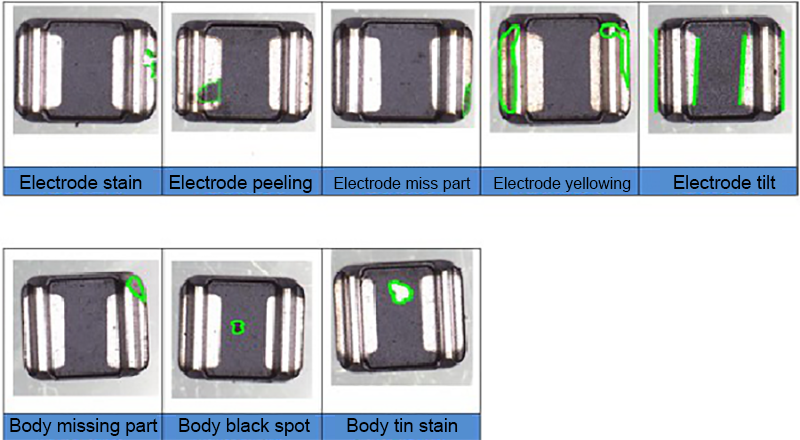

For example, the appearance of electrode defect detection, visual appearance inspection can detect items such as electrode size measurement, electrode dirt, peeling, chipping, yellowing, and tilting.

Electronic components body missing corners, black spots, tin staining, etc. After visual defect detection, we can sort qualified and unqualified parts into different material areas through sorting equipment.

Electronic component appearance inspection items: Electrode size measurement and electrode dirt, peeling, chipping, yellowing, tilting; body missing corners, black spots, tin staining.

Electronic component appearance inspection cases

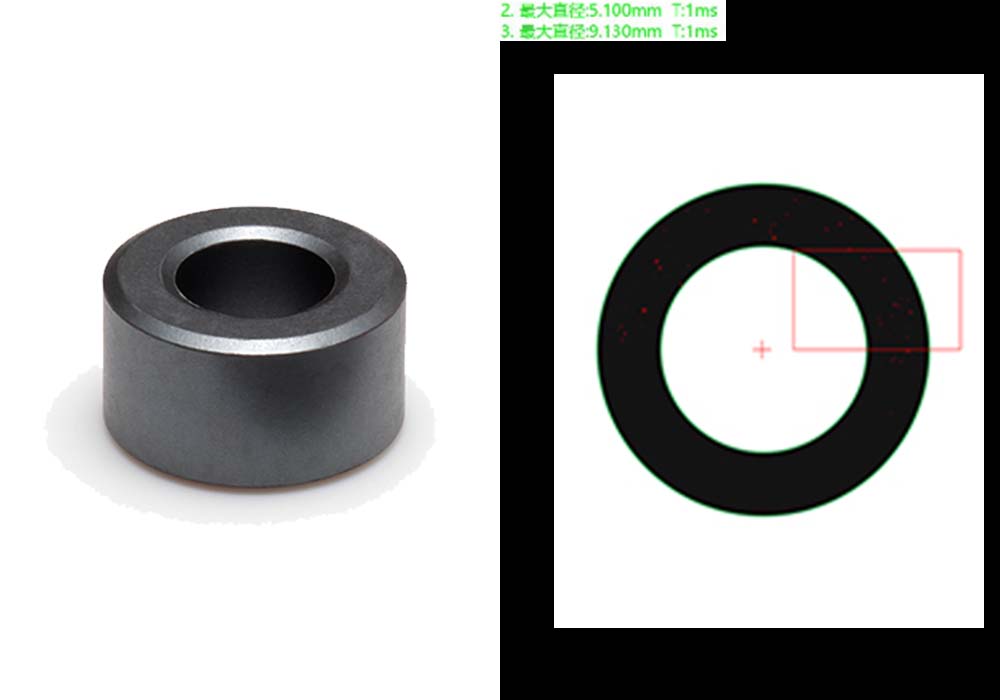

Dimension Measurement:

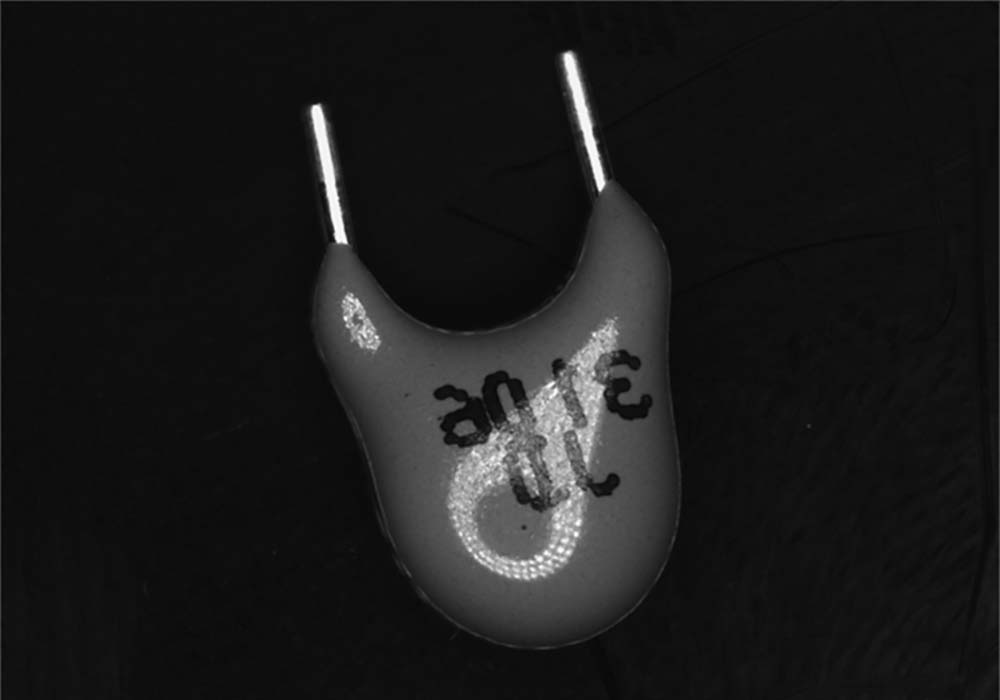

Surface Detection:

Intsoft Technology Co., Ltd., engaged in optical and visual inspection for many years, is a professional manufacturer of visual inspection equipment, specializing in CCD visual inspection, automated inspection. The company’s main visual inspection equipment, optical inspection equipment, provides visual inspection equipment for various industries. We can provide non-standard product visual inspection equipment, electronic component inspection equipment, and customized services for related product visual inspection according to customers’ different inspection needs.