We may have eaten biscuits from brands like Oreo, Ferrero, and McVitie’st, but we may not have paid attention to the detection process of these biscuits. These delicious biscuits are made by mixing flour, sugar, eggs, oil and other raw materials, stirring, extruding, baking, etc. Due to the various ingredients and the need for heat treatment, the surface of the finished biscuits is uneven and has many colors. If there are foreign matters on the surface, it is not easy to distinguish them.

Through machine vision technology, biscuit manufacturers can realize intelligent inspection of biscuit appearance. This includes timely detection of abnormal conditions such as biscuit size, shape, color, cracks, etc., and comparison and analysis with ideal templates, elimination of unqualified biscuits, and saving these defect data to the database for AI training to improve the inspection speed and success rate of subsequent biscuit inspections.

The following is a biscuit detection case shared by Intsoft Tech.

Project difficulty

The biscuit surface has many colors and bumps, which are difficult to distinguish from foreign matters and defects on the surface. In addition, the camera is required to be more demanding when shooting while moving.

Visual system solution

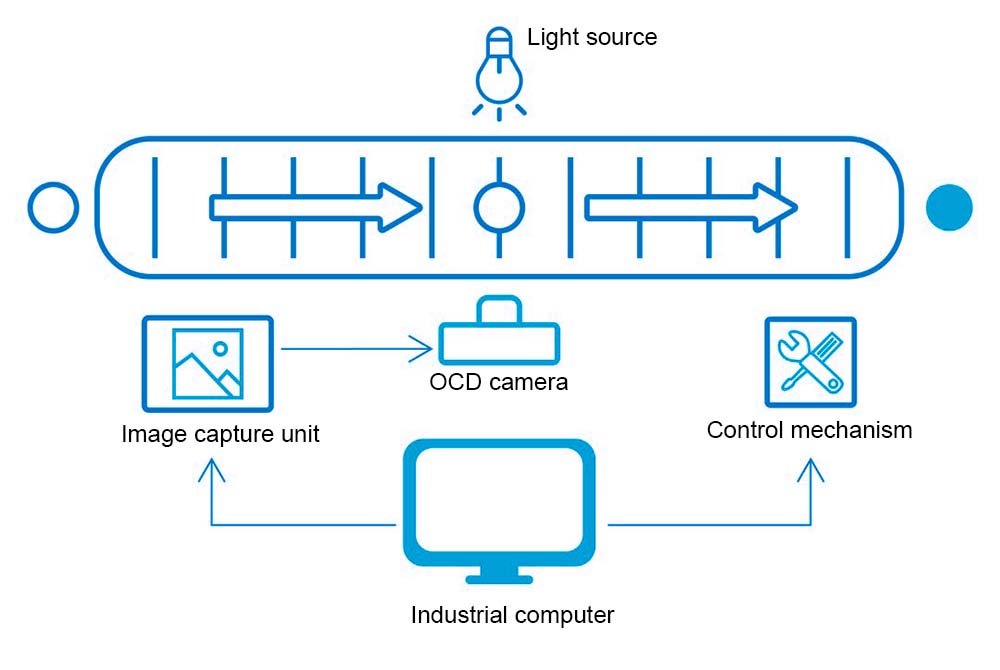

The visual system is mainly composed of industrial cameras, light sources, lenses, and software systems.

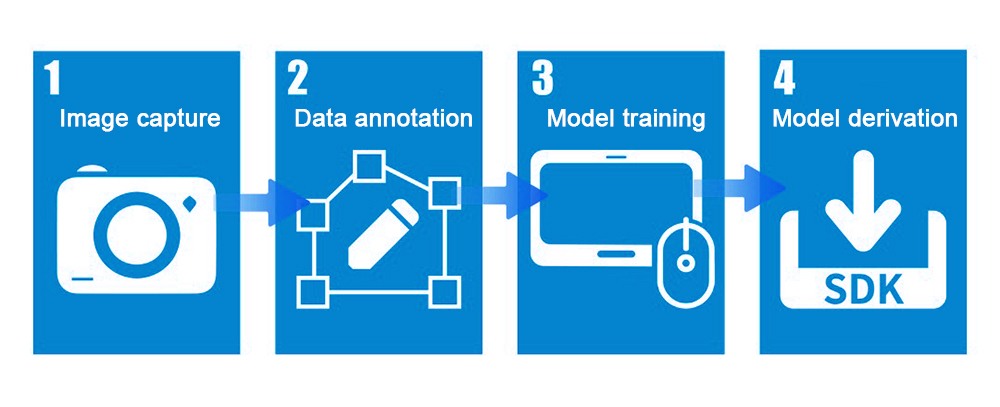

The camera, light source, and lens work together to complete the image acquisition task; the system software can mark the defect features of uploaded images and use deep learning technology to complete the model training task to achieve directional recognition and detection of marked feature defects. The operation is simple and easy to master.

Lighting and imaging solution

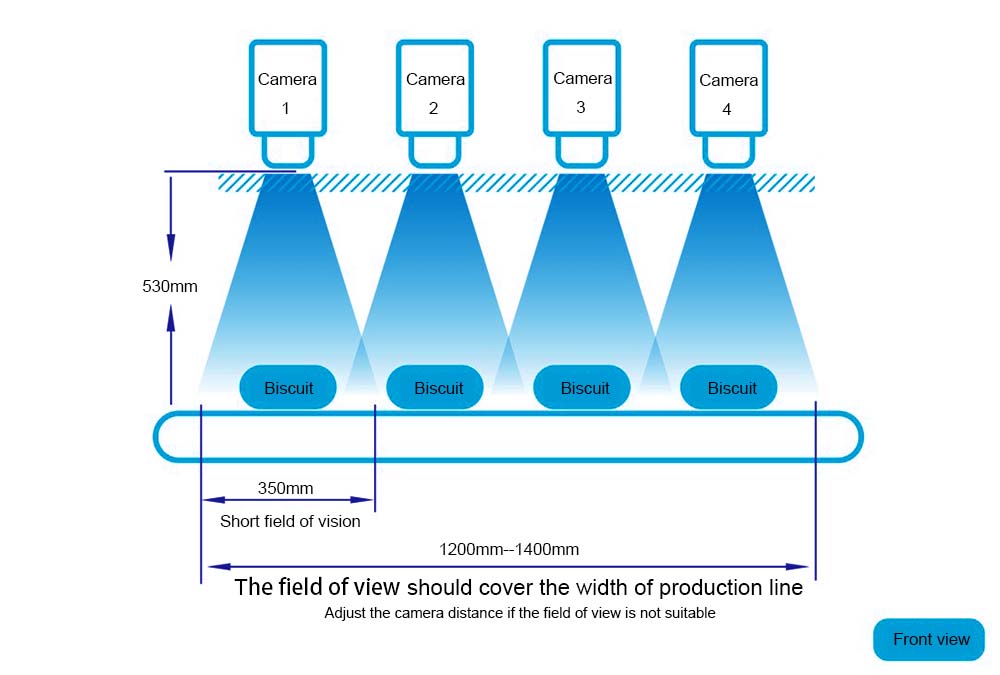

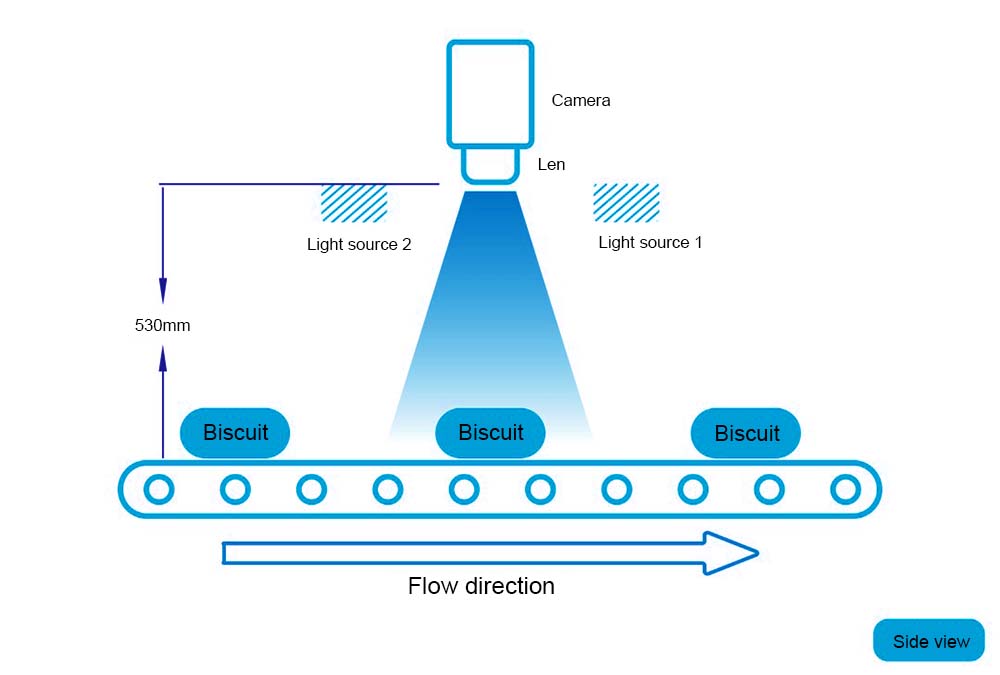

High-brightness strip light source is used, and two light sources are fixed on both sides of the entire line of cameras. The installation height is about 450-500mm, which can be adjusted according to actual conditions. If a diffuser is installed, the illumination will be more uniform.

In the dynamic shooting mode of the assembly line, 4 cameras are fixed at equal intervals directly above the assembly line, and the photos are taken perpendicular to the front of the product. The long side direction of the camera corresponds to the flow direction of the assembly line, and the short side direction of the camera corresponds to the width direction of the assembly line.

Algorithm solution

The software system is used for pixel segmentation to quickly implement data annotation and model training. Under the same model, the software supports multiple defect tags, can detect multiple defects in a picture at the same time, and can classify defects. Depending on the defect type, corresponding labels are established and annotated.

Detection results

The software system can display the defect detection results in real time and record the results in time, which greatly improves the efficiency of manufacturers in identifying biscuit defects.