To prevent food from staling, manufacturers generally place deoxidizers and desiccants in food packaging. Deoxidizers, as food preservatives, can prevent food from spoiling by controlling the amount of oxygen in food packaging; desiccant can absorb moisture in the gas inside the packaging, thereby achieving internal dryness of the packaging and keeping the food for a longer shelf life.

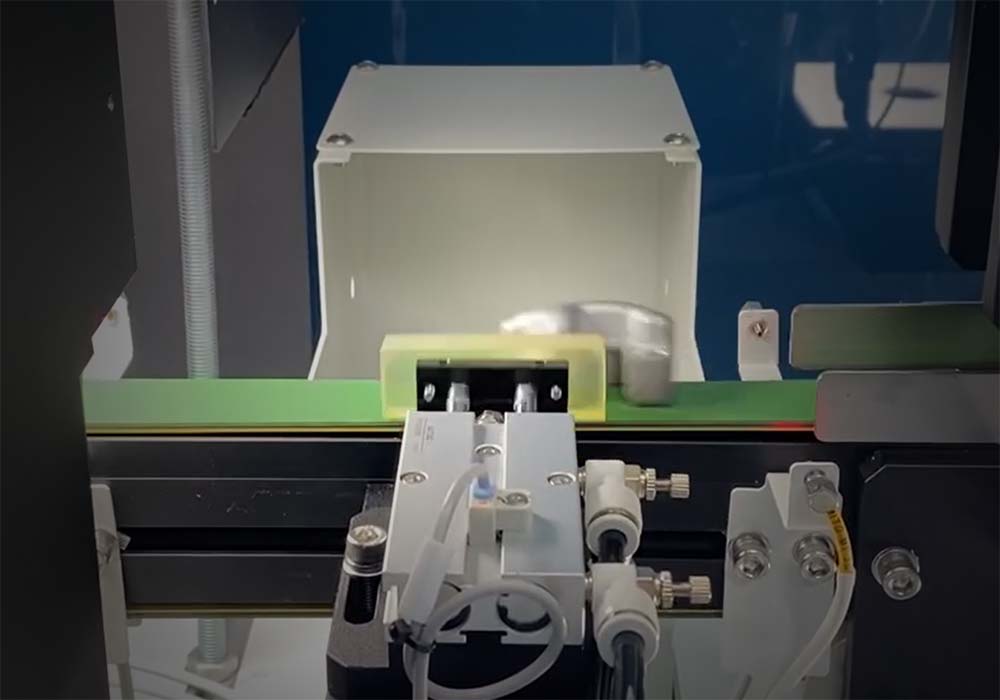

Food safety and the loss of brand reputation caused by the leakage of chemical components inside desiccant and deoxidizer are very costly. Traditional desiccant and deoxidizer production and packaging are mainly carried out through manual testing, which is costly and has poor risk control capabilities. Therefore, how to use machines instead of manual labor to achieve rapid testing of desiccant and deoxidizer production and packaging has become a concern for manufacturers.

Current status of machine vision detection industry

1. Most existing manufacturers are upgrading and renovating existing machines, so it is crucial to quickly determine whether the current machine is suitable for visual upgrades.

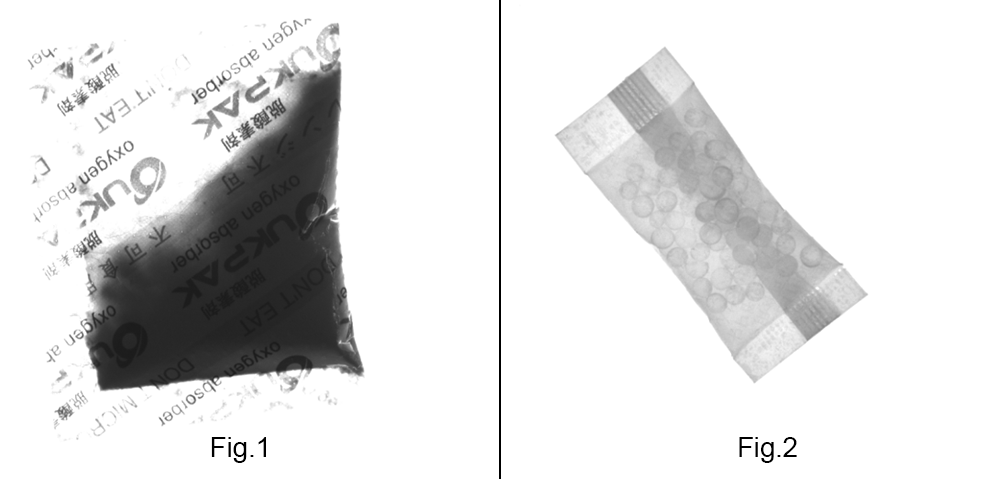

2. Visual inspection as a replacement for manual inspection has a major premise: visible to the human eye. Most deoxidizer packaging is opaque. Silicone desiccant detection is a transparent product. How to solve the imaging problem of opaque products and the detection problem of transparent products is a difficulty in the industry.

3. The same machine may involve many different types, colors, and sizes of packaging paper. How to quickly verify the feasibility of each product is a criterion for considering choosing a machine vision company to cooperate with.

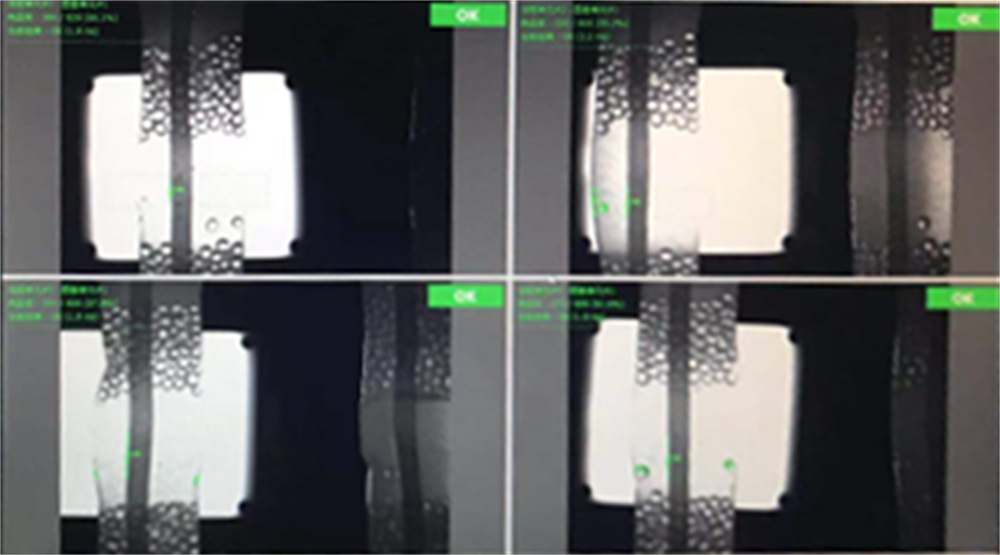

Industry detection requirements:

1. Filling status of desiccant and deoxidizer packaging.

2. Whether there is material stuck to the seal, empty packages, or connected packages.

3. Daily data aggregation to form a truly intelligent upgrade.

Detected product image

Fig.1 Opaque deoxidizers packaging

Fig.2 Transparent silicone desiccant packaging

Detection Image Showcase

Silicone desiccants detected image:

Deoxidizers detected image:

Intsoft Tech has been deeply involved in the industry for many years. With rich experience and more than a thousand successful cases of helping customers realize automated production of machine vision, there is enough capacity to provide one-stop machine vision solutions for enterprises.

During the project cooperation verification and implementation phase, the Intsoft Tech Intelligent Manufacturing Solution Team will provide overall rationalization suggestions in the visual system integration part to adapt to the actual on-site transformation or upgrade needs of the plant, fully meet the space conditions of different machines, and avoid unnecessary cost expenditures during the upgrade process.