In the production of pigments packaged in blister trays, the precise arrangement and orientation of color elements are of the utmost importance. These pigment sets are not only functional tools for creative expression, but also serve as visually appealing retail products. Intsoft Tech, a leading provider of machine vision solutions, offers a specialized application to help manufacturers ensure flawless color layout and presentation on pigment blister trays.

Intsoft Tech’s vision system adapts high-resolution cameras and sophisticated algorithms to carefully examine the layout of each paint color on the blister tray. Our solution can pinpoint the exact location of each color region, verifying that they are positioned correctly within the specified tolerances. This level of precision is essential to maintain the visual harmony and consistency of the pigment for retail use.

Identify whether pigments are arranged in a specific color order

The visual system checks the position of each pigment color on the Blister Tray. The system can accurately locate the coordinates of each color on the tray to ensure that they are neatly arranged in the preset order. Any deviation in the color order will be detected and marked by the system in time.

Correct front and back orientation

The orientation of the pigment on the front and back of the Blister Tray is equally important. Intsoft Tech’s machine vision solution checks whether each color block is oriented the same on the front and back to ensure colors are not reversed during use. This meticulous inspection helps to improve the overall quality image of the final product and create a high-quality, professional user experience for users. The characters printed on the front and back of the pigment are different. The vision system will accurately determine whether the front and back are placed incorrectly based on the difference in characters.

Accuracy of printed information

In addition to the color itself, the printed information on the Blister Tray must also be accurate. Intsoft Tech’s system can identify and verify key information such as brand logo, model, instructions, etc. on each package to ensure that it is completely consistent with the design requirements. This not only maintains the brand image, but also makes it easier for consumers to correctly identify and purchase.

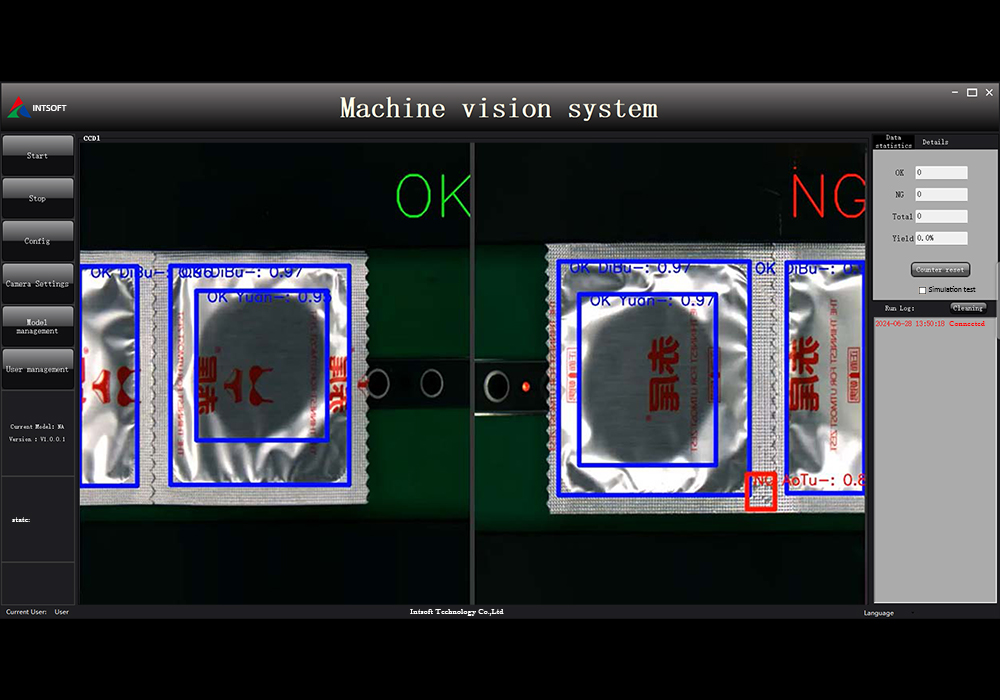

Real-time quality monitoring

Intsoft Tech’s machine vision solution can be seamlessly integrated into the production line to monitor the placement of pigments in each Blister Tray in real time. Once any deviation is detected, the system will immediately provide feedback so that staff can make timely corrections. This not only greatly improves inspection efficiency, but also minimizes the risk of unqualified products entering the market.

Inspection items:

1. Pigment missing inspection.

2. The order and direction of the pigments on the blister.

3. The correctness of the characters.

4. Whether the front and back sides are placed incorrectly.

Note: Image should be visible clearly and placed in the detectable area.

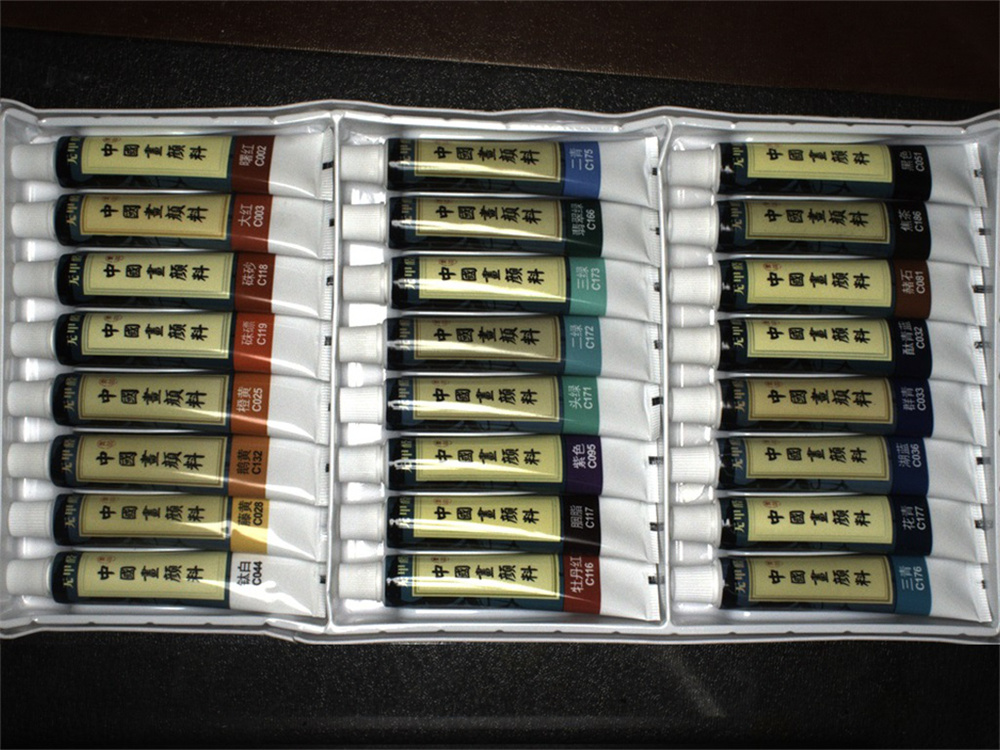

Inspection Image

Correct placement of pigment

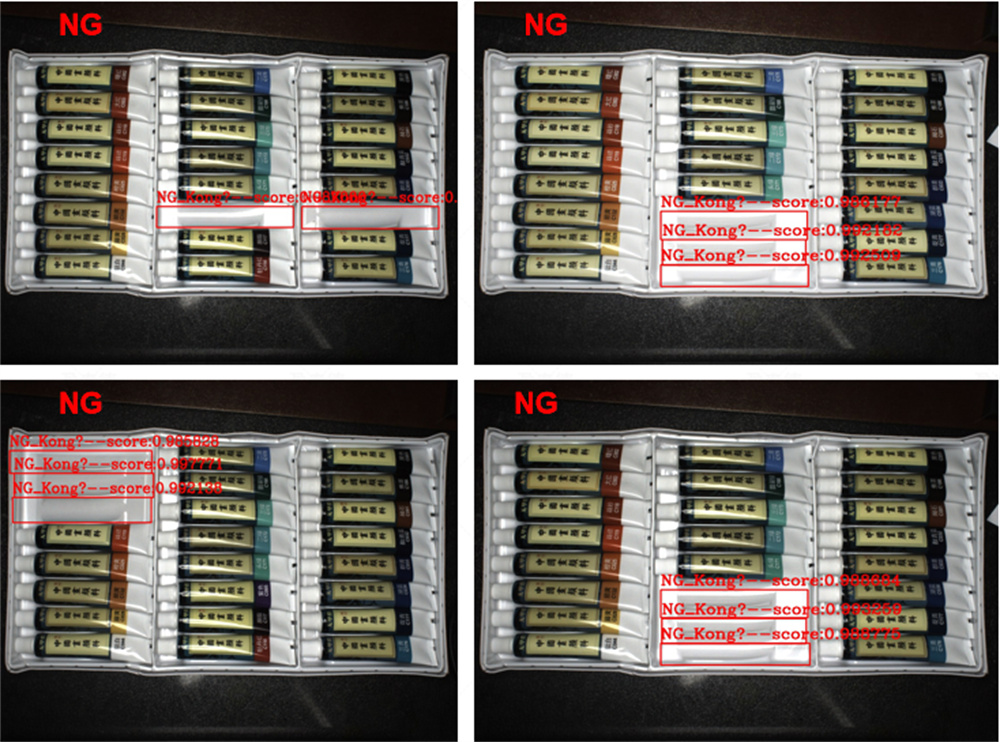

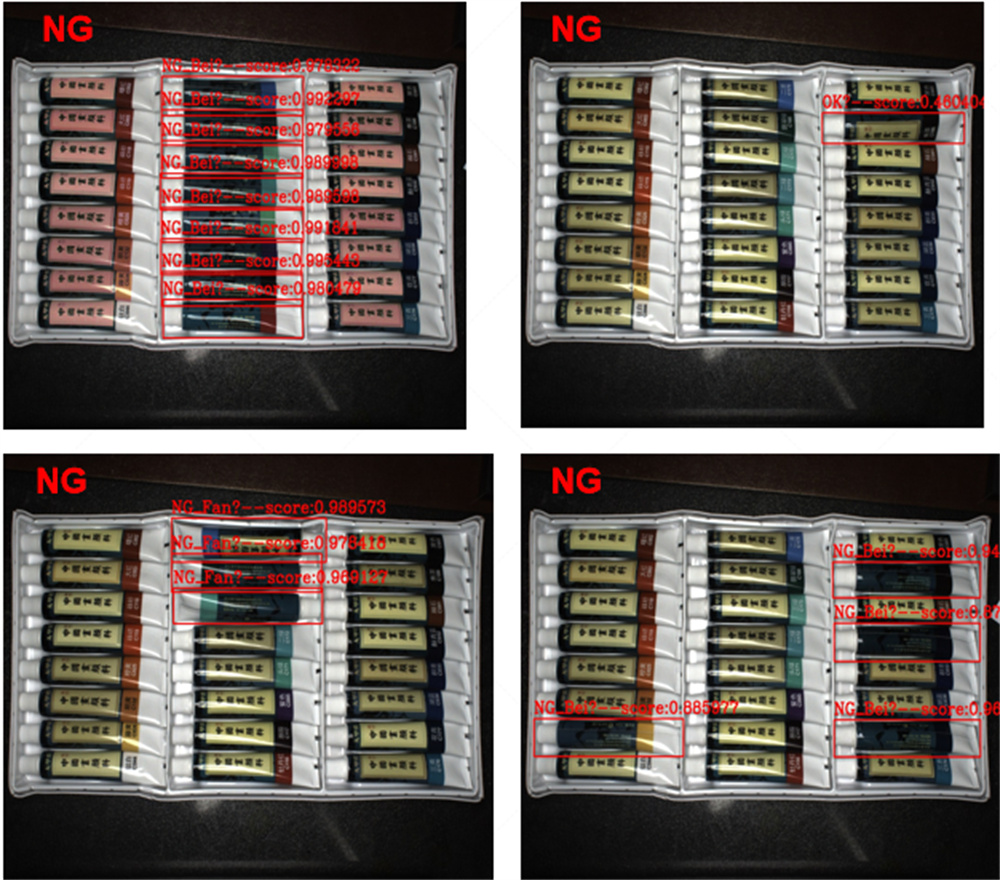

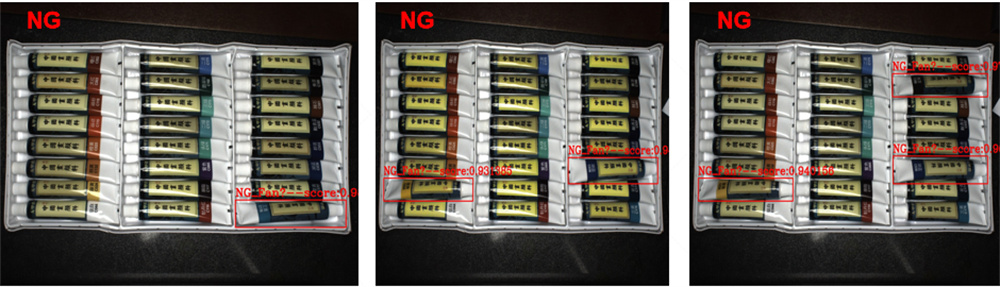

Wrong front and back placement, pigment missing, wrong direction placement:

Missing pigment: