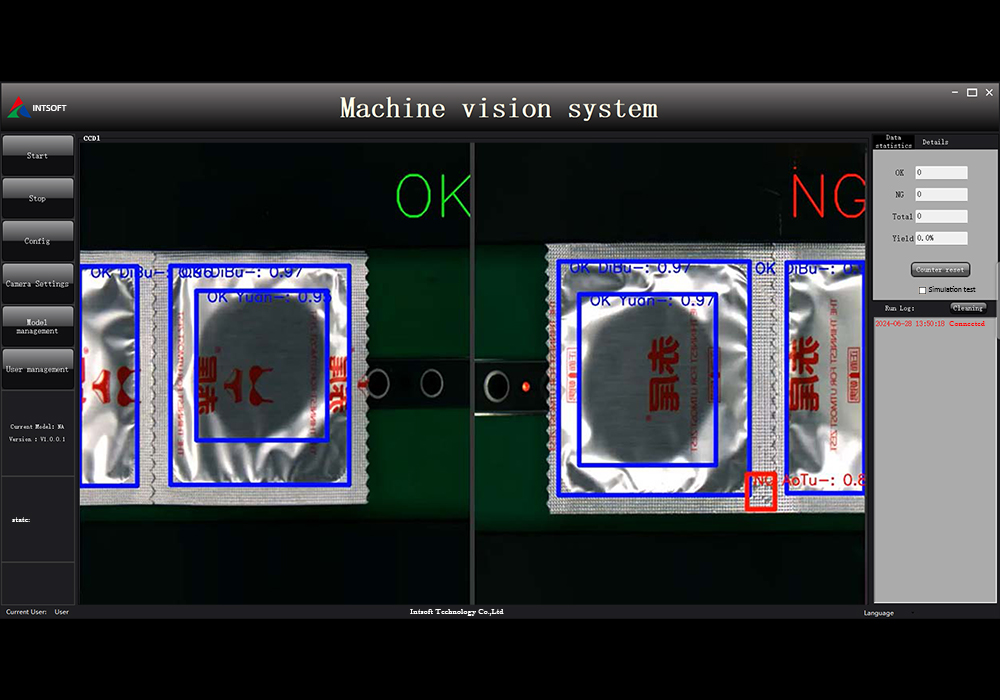

Intsoft Tech delivers condom packaging inspection machine this week.

After two months of design and production, this condom packaging inspection machine was delivered to our condom manufacturer customer as scheduled. This machine solves the problems that have plagued appearance inspection for a long time:

1. The silver reflective outer packaging reflects light when capturing images, which easily causes inaccurate image data and leads to system misjudgment.

2. Condoms are inside the silver packaging, and the position of the condoms must be determined based on the bulges and wrinkles left by the condoms on the packaging.

Through machine deep learning, the model trained by Intsoft Tech can accurately detect condoms with an accuracy rate of more than 99%.

The customer already has a complete line of automatic condom packaging. What we need to do is install an extended production line after condoms are automatically packaged, introduce condoms into camera obscura, use industrial cameras to capture images, and determine whether the condoms are defective and the type of defects based on the images. Finally, the defective condoms are classified according to the type of defect, and the qualified condoms flow directly to the qualified storage box.

This small production line, which produces more than 200 condoms per minute, can detect:

1. Whether the font print on the packaging is correct.

2. Whether the edge of the condom is pressed into the sealing edge.

3. Whether the packaging is damaged, dirty, and other defects.