Vision inspection works like a smart camera that takes pictures of things, looks closely at them to find any problems or special features, and then decides whether they are good or bad based on what it sees.

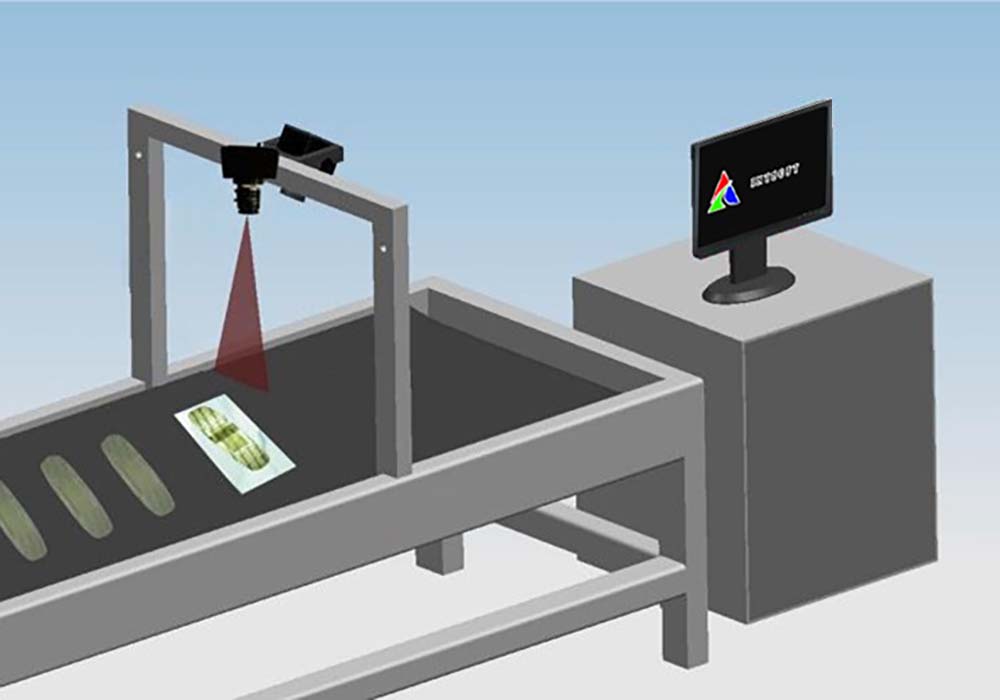

As a key component of modern automation and quality control processes, machine vision system operates by harnessing the power of advanced imaging technology to scrutinize and evaluate objects or scenes with precision and efficiency. At the core of this technology is a sophisticated camera system that captures high-resolution images of the subject under review. These cameras can be strategically positioned to capture the object from different angles, ensuring a comprehensive view for inspection purposes. The quality and resolution of these images are paramount, as they form the basis for subsequent analysis and decision-making within the vision inspection system.

Once the images are acquired, a series of preprocessing techniques are applied to refine and enhance the visual data. This preprocessing phase typically involves tasks such as noise reduction, image calibration, and normalization to optimize image quality for subsequent analysis. Following this, the images are segmented, effectively dividing them into distinct regions of interest and background. This segmentation process is critical for isolating the object to be inspected, facilitating focused analysis of specific areas and features within the image.

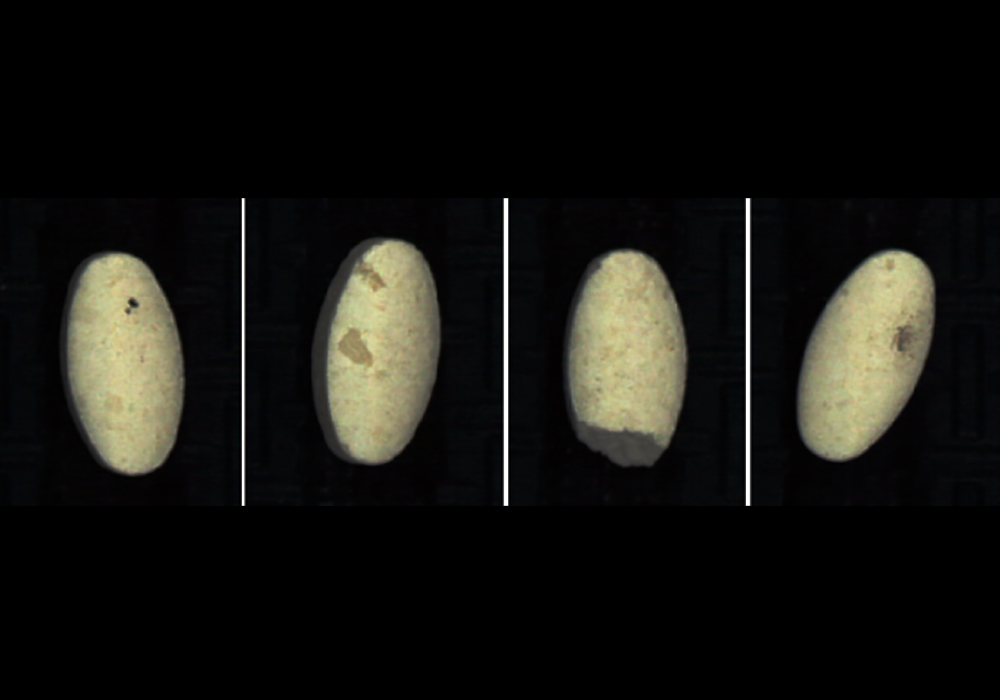

Feature extraction represents a pivotal stage in the vision inspection workflow, where key object attributes and characteristics are identified and isolated for further analysis. Features such as edges, textures, colors, shapes, and patterns are extracted from the segmented images. These extracted features serve as the basis for subsequent pattern matching and recognition algorithms, enabling the system to compare these features against predefined templates or models. Using sophisticated algorithms and machine learning techniques, the system can discern anomalies, defects, or deviations based on the extracted features, allowing accurate and reliable inspection results.

The decision-making process within a vision inspection system depends on the culmination of these previous steps, where the system evaluates the extracted features, matches them against predefined criteria, and makes informed decisions about the quality, integrity, or conformity of the inspected object. Whether it involves identifying defects, classifying objects, measuring dimensions, or verifying assembly processes, the system’s decision-making capabilities play a pivotal role in ensuring efficient and accurate inspection results. Ultimately, seamless integration of hardware components (cameras, lighting) with sophisticated software algorithms empowers vision inspection systems to deliver robust and automated inspection capabilities across a diverse range of industries, revolutionizing quality control processes and driving operational excellence.