Color recognition is a fundamental capability of machine vision systems, enabling them to accurately identify and classify colors present in captured images or video frames. This capability is achieved through a combination of image acquisition, color space conversion, color segmentation, color feature extraction, and color classification techniques.

To understand how machine vision systems achieve color recognition, we need to start with the basics of how color is perceived and represented in the digital world.

The Human Visual System and Color Perception

The human eye has specialized cells called cones that are responsible for color vision. There are three types of cones, each sensitive to a different range of visible light spectrum: red, green, and blue. When these three cone types are stimulated in different combinations, the human brain is able to perceive a wide range of colors.

The way the human visual system perceives color can be represented using a color model, such as the RGB (Red, Green, Blue) color model. In this model, each color is defined by a combination of red, green, and blue values, typically ranging from 0 to 255. By combining different amounts of red, green, and blue, the human eye can perceive millions of distinct colors.

Digitizing Color Information

In the digital world, images and video are represented as a grid of pixels, where each pixel has a specific color value. To capture and represent color information in digital form, machine vision systems use image sensors, such as charge coupled device (CCD) or complementary metal oxide semiconductor (CMOS) sensors.

These image sensors are designed to capture the intensity of light across the visible spectrum, similar to the way the human eye’s cones work. The sensor’s photosensitive elements (pixels) are arranged in a grid, and each pixel is sensitive to a specific range of the visible light spectrum, typically corresponding to the red, green, or blue color channels.

When light hits the image sensor, pixels generate electrical signals proportional to the intensity of the light they receive. These electrical signals are then digitized and stored as numerical values, representing the color information for each pixel in the image.

Color Representation in Digital Imaging

Digital color information is typically represented using a color model, such as the RGB color model mentioned earlier. In this model, each pixel in the digital image is assigned a specific combination of red, green, and blue values, which collectively determine the perceived color of that pixel.

For example, a pixel with an RGB value of (255, 0, 0) would be perceived as pure red, while a pixel with an RGB value of (128, 128, 128) would be perceived as a shade of gray.

It is important to note that the range of colors that can be represented using the RGB color model is limited by the capabilities of the display device or image sensor. Different display technologies, such as computer monitors, televisions, or projectors, may have slightly different color reproduction capabilities, which can affect perceived colors in a digital image.

Color Recognition in Machine Vision Systems

Now that we have a basic understanding of how color is perceived and represented in the digital world, let’s explore how machine vision systems perform color recognition.

The process of color recognition in machine vision systems typically involves the following steps:

Image Acquisition:

The first step is to capture an image or video frame using the machine vision system’s image sensor. This sensor converts incoming light into digital signals that can be processed by the system.

Color Space Conversion:

The captured image is often represented in a different color space, such as RGB, than the one used for color recognition. Machine vision systems may need to convert image data into a more suitable color space, such as Hue-Saturation-Value (HSV) color space, which is often better suited for color recognition tasks.

Color Segmentation:

The next step is to identify and separate the different color regions within the image. This process is known as color segmentation and involves the use of various algorithms to group pixels with similar color characteristics into distinct regions or objects.

Color Feature Extraction:

Once the color regions have been identified, the machine vision system extracts relevant color features from them. These characteristics may include the average color value, range of color values, dominant color, and distribution of color values within the region.

Color Classification:

The final step is to classify the color regions based on the extracted color characteristics. This involves comparing the color features to a predefined set of color classes or categories, which the machine vision system has been trained to recognize. The classification process can be done using various algorithms, such as k-nearest neighbors, support vector machines, or deep learning-based models.

Colour Recognition Challenges and Techniques

While the basic principles of color recognition in machine vision systems are straightforward, there are several challenges that need to be addressed to achieve reliable and accurate color recognition performance.

Lighting Conditions:

The quality and intensity of lighting conditions can significantly affect the way colors are perceived by the machine vision system. Changes in ambient light, shadows, and reflections can alter the color values captured by the image sensor, resulting in inaccurate color recognition. Machine vision systems often employ techniques such as color constancy, which aims to correct the effects of lighting conditions, to improve the reliability of color recognition.

Color Constancy:

Color constancy is the ability to perceive the same color under different lighting conditions. Machine vision systems can implement color constancy algorithms, such as grey-world or white-balance, to adjust the color values in the image to account for the effects of the lighting environment.

Color Spaces and Color Models:

The choice of color space and color model can significantly impact the performance of color recognition. Different color spaces, such as RGB, HSV, or CIELab, have their own strengths and weaknesses when it comes to color representation and discrimination. Machine vision systems may need to experiment with different color spaces to find the one that works best for their specific application.

Color Calibration:

To ensure consistent color recognition performance, machine vision systems often need to be calibrated. This involves capturing reference images of known color targets and using them to adjust the system’s color response, account for sensor variations, and optimize the color recognition algorithms.

Machine Learning and Deep Learning:

In recent years, the use of machine learning and deep learning techniques has significantly improved the accuracy and robustness of color recognition in machine vision systems. These techniques allow the system to learn and adapt to complex color patterns and distributions, providing better performance than traditional rule-based color recognition algorithms.

Machine learning-based approaches to color recognition often involve training a model, such as a convolutional neural network (CNN), on a large dataset of labeled color images. The trained model can then be used to classify colors in new images with high accuracy, even in the presence of challenging lighting conditions or color variations.

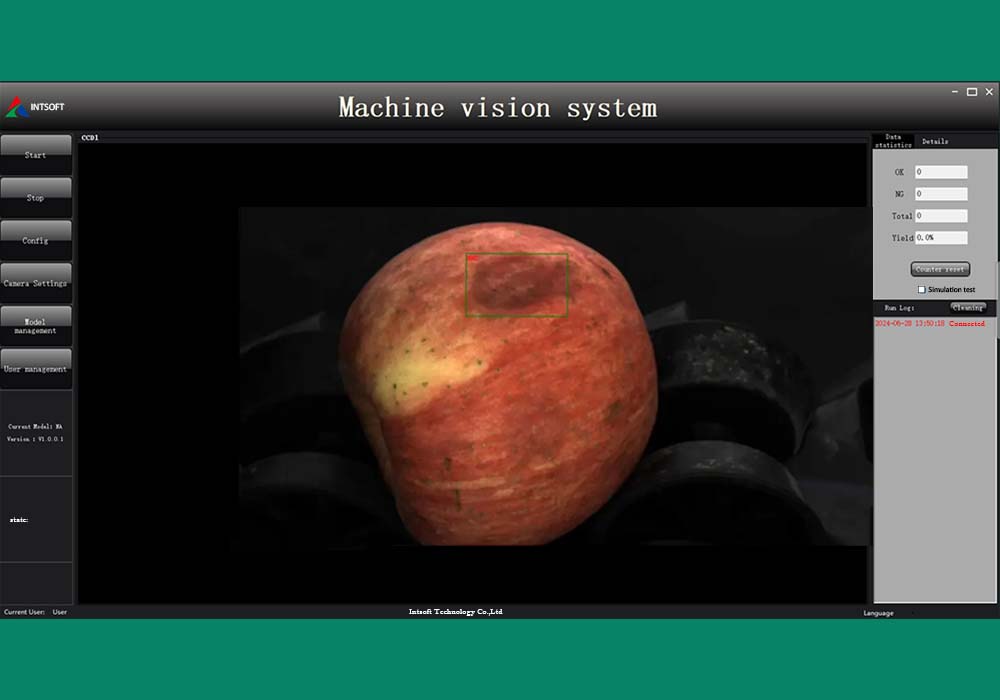

Example of Color Recognition in Machine Vision

To illustrate how color recognition works in a practical application, let’s consider a simple example of a machine vision system used in a manufacturing environment to inspect the color of painted parts.

In this scenario, the machine vision system is equipped with a high-resolution camera and is positioned to capture images of painted parts as they move along a conveyor belt. The system’s task is to ensure that the color of the painted parts matches the specified color requirements.

Here’s how the color recognition process might work:

Image Acquisition:

The camera captures a series of images of the painted parts as they move through the inspection zone.

Color Space Conversion:

The system converts captured RGB images into HSV color space, which is more suitable for color recognition tasks.

Color Segmentation:

The system uses image segmentation algorithms to identify individual painted parts in the image and separate them from the background.

Color Feature Extraction:

For each identified painted part, the system extracts relevant color characteristics, such as the average hue, saturation, and value (brightness) values, as well as the distribution of these values within the part.

Color Classification:

The system compares the extracted color features to a predefined set of color classes, which represent acceptable color ranges for the painted parts. This comparison is typically done using a classification model based on machine learning, such as a support vector machine or neural network.

Quality Inspection:

Based on the color classification results, the system determines whether the painted part meets the color requirements. If the part falls outside the acceptable color range, it is marked as defective, and appropriate quality control actions can be taken.

Throughout this process, the machine vision system may also employ techniques like color constancy and color calibration to ensure the accuracy and reliability of the color recognition results, even in the face of changing lighting conditions or sensor variations.

By implementing this color recognition pipeline, the machine vision system can automate the quality inspection process, reducing the need for manual inspection and ensuring consistent color quality in manufactured parts.

While the basic principles of color recognition are straightforward, there are several challenges, such as lighting conditions, color constancy, and color space selection, that need to be addressed to ensure reliable and accurate performance. By incorporating advanced techniques such as as machine learning and deep learning, modern machine vision systems have significantly improved their color recognition capabilities, making them essential tools in a wide range of industrial and commercial applications.