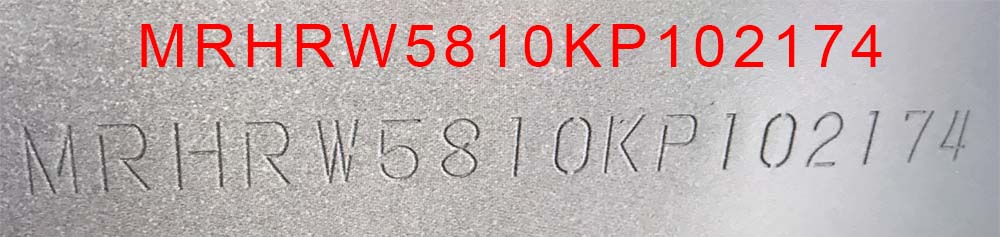

Objects that we come into contact with in our daily lives often have printed characters, such as label characters on clothing, specification characters on electrical appliances, production dates on food packaging, etc. These printed characters are used to describe information such as production date, brand, origin, specifications, etc., so that consumers can learn more about the information of the object and enhance their trust in the manufacturer of the object.

When these characters are printed, it is inevitable that some characters have defects, such as burr, position deviation, excess ink, missing, etc. Poor character printing will cause customers to complain to the manufacturer at least, and at worst, the user’s health will be harmed due to missing information.

To overcome this problem, manufacturers will conduct strict inspections of products before they leave the factory. The traditional inspection method is to use manual visual inspection. Although visual inspection is flexible, it can make different judgments about various errors. However, due to the large number of products, many varieties, and high labor consumption, long-term inspection will cause eye fatigue or confusion and misjudgment due to subjective emotions.

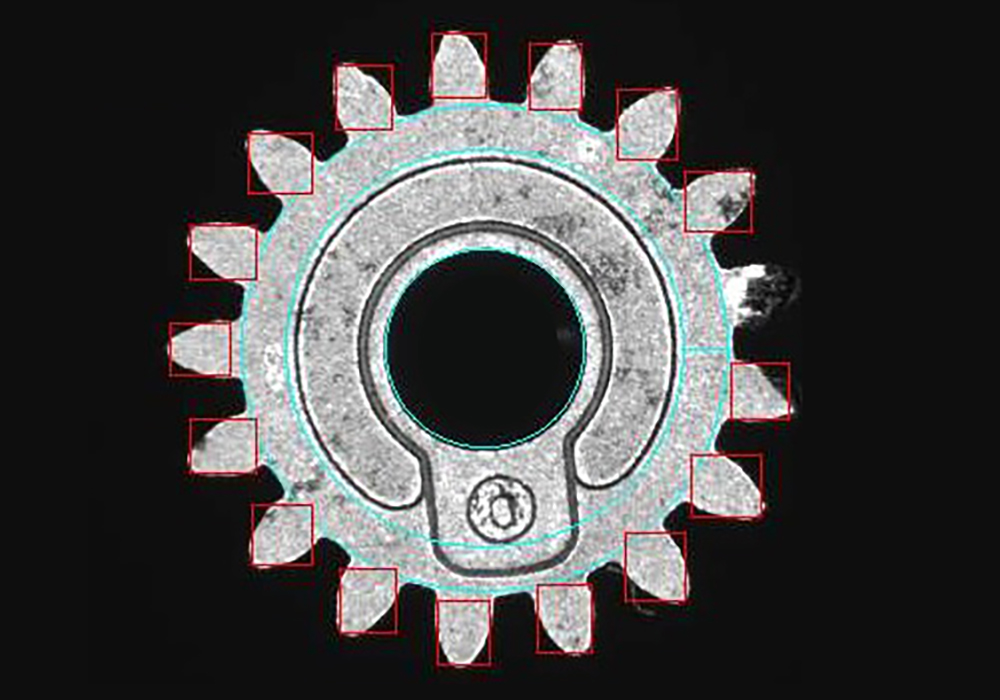

Using machine vision inspection technology, it can distinguish the defect image of the product from the background image according to different product materials, defect conditions and customer needs, by using different light sources and different illumination angles, and cameras with different pixels, and then using color, grayscale, shape, size, etc. of the defect image to identify defects, and using different algorithms to write software through image effects, and develop software in combination with customer needs. High-precision, high-efficiency, high-stability real-time inspection, analysis and calculation of products to determine whether the products are qualified can effectively improve the inspection speed and accuracy of the production line, greatly improve production and quality, reduce labor costs, and prevent misjudgments caused by human eye fatigue.

Functional characteristics of machine vision detection technology applied in character recognition detection:

1. Detect barcode/character printing defects, displacement, excess ink, missing printing, completeness, etc.

2. Detects whether the direction of the object is correct.

3. Static or dynamic detection is available.

4. OK/NG product system outputs corresponding control signals.

Machine vision inspection technology is used in optical character recognition inspection:

1. 1D code, 2D code, OCR/OCV character visual inspection, ocr data extraction.

2. Bottle cap character visual inspection.

3. Mobile phone case character inspection.

4. Package character/label visual inspection.

5. Power battery appearance character inspection.

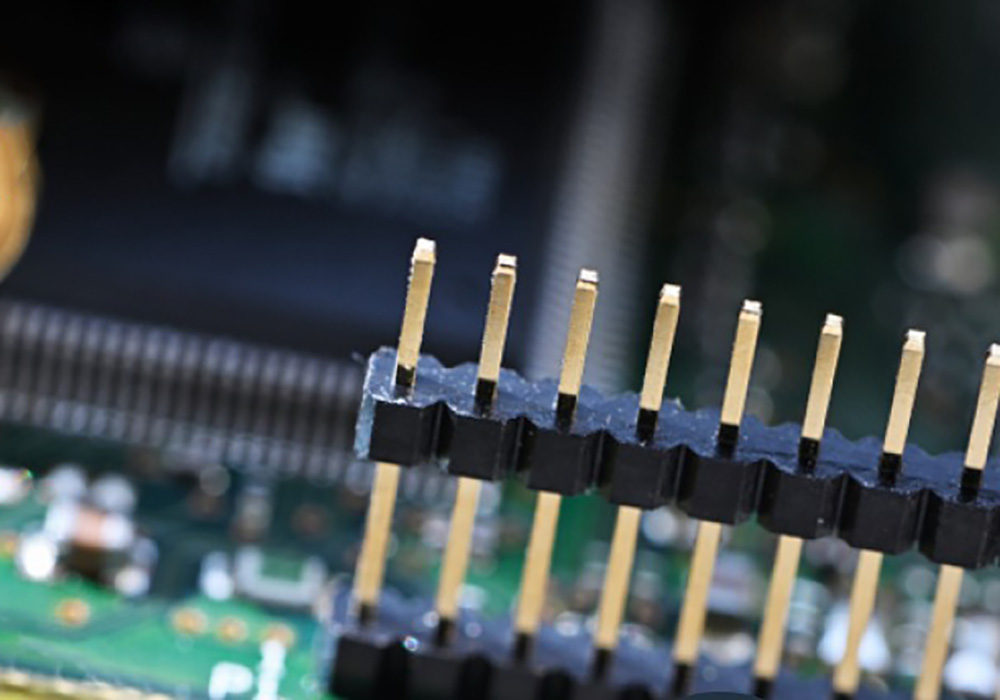

6. PCB circuit board character code reading.

7. Electronic capacitor screen printing inspection, electronic component machine vision inspection.

8. Characters and barcodes on semiconductor chips.

9. Automotive manufacturing part coding, symbols.

10. Printing and packaging plants, food, beverage, medicine and consumer product packaging label visual inspection.

Advantages of machine vision inspection technology in character recognition applications:

1. Higher efficiency: Machine vision inspection is much faster, can inspect hundreds or even thousands of components per minute, and can work continuously for 24 hours.

2. Higher accuracy: Not subject to subjective control, as long as the parameters are the same, multiple machines with the same configuration can guarantee the same accuracy.

3. Lower overall cost: Machines are more effective than manual inspection, and in the long run, machine vision inspection costs are lower.

4. Digital statistical management: Measure data and generate reports after measurement without manually adding them one by one.

5. Applicable to dangerous inspection environments: The machine can perform inspection work well in harsh and dangerous environments, and in occasions where human vision cannot meet the needs.

6. More objective and stable: During manual inspection, inspection results will be affected by personal standards, emotions, energy and other factors. The machine strictly follows the set standards, and the inspection results are more objective, reliable and stable.

7. Simple maintenance: low technical requirements for operators, long service life and other advantages.

In general, machine vision inspection can efficiently, accurately and stably detect the numbers and barcodes of various code systems. Compared to manual inspection, it is more objective, non-contact and highly accurate.

Especially in the field of industrial production, it has a strong application value in repetitive and mechanical work. For enterprises, it not only ensures the stability of product quality, but also improves product competitiveness.